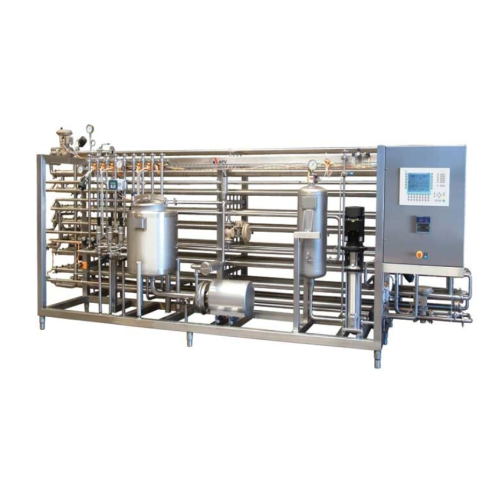

Tubular Uht processing for dairy products

Experience efficient high-pressure thermal processing with tubular UHT technology for diverse dairy and beverage applications, ensuring consistent product quality and extended shelf life for heat-sensitive liquids.

Processes Liquid Dairy and Beverage Products

The Tubular Ultra High Temperature (UHT) Plant from APV is designed to provide flexible handling and superior thermal processing for a diverse range of liquid dairy and beverage products. It utilizes a tubular heat exchanger system that ensures efficient heat transfer and back pressure tolerance up to 870 psi (60 bar), offering remarkable performance in high-pressure environments. With approximately 85% heat regeneration, this equipment minimizes energy consumption, reducing operational costs for processors.

Ideal for applications like milk, flavored milk, and coffee creamers, the plant supports production of end products such as whole milk, strawberry milk, and iced latte beverages. It operates continuously and integrates seamlessly into existing production lines, thanks to its pre-assembled, factory-tested design. The plant’s operator-friendly setup, along with its easy inspection features, reduces maintenance requirements and enhances uptime.

Constructed with material options that ensure corrosion resistance, the Tubular UHT Plant complies with ASME, PMO, and 3-A standards, ensuring safety and reliability in food-grade environments. Customization options are available, providing engineering support for specific production needs.

Benefits

- Enhances production versatility with its ability to handle a wide range of liquid products.

- Reduces energy costs through high-efficiency heat regeneration.

- Minimizes maintenance with easy access for inspection and cleaning.

- Ensures operational reliability under high-pressure conditions.

- Supports compliance with industry standards, ensuring safe and reliable processing.

- Applications

- Cream, Beverages, Milk, Dairy products, Custard, Milk shake, Ice cream mix, Coffee cream, Flavored milk

- End products

- Whipped cream, Hazelnut coffee creamer, Vanilla custard, Banana milkshake, Chocolate ice cream base, Yogurt drink, Strawberry milk, Iced latte beverage, Whole milk

- Steps before

- Homogenization, Heat Exchanging, Mixing, Blending

- Steps after

- Cooling, Aseptic Packaging, Storage, Distribution

- Input ingredients

- milk, flavored milk, coffee cream, cream, ice cream mix, custard, milk shake

- Output ingredients

- UHT milk, UHT flavored milk, UHT coffee cream, UHT cream, UHT ice cream mix, UHT custard, UHT milk shake

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Back pressure tolerance

- up to 870 psi (60 bar)

- Heat regeneration efficiency

- approx. 85%

- High pressure tolerance

- Yes

- Working pressure tolerance

- Up to 870 psi (60 bar)

- Heat regeneration

- Approx. 85%

- Automation level

- Operator-friendly, possibly PLC-controlled

- Batch vs. continuous operation

- Continuous

- Inspection ease

- Easy inspection of product and medium surface

- Energy efficiency

- Low energy cost

- Product Range Flexibility

- Wide range

- Control panel type

- Operator-friendly

- Machine footprint

- Pre-assembled

- Tank shape and size

- Robust and flexible

- Back pressure tolerance

- Up to 870 psi (60 bar)

- Heat regeneration efficiency

- Approx. 85%

- Factory testing

- Pre-assembled and factory tested