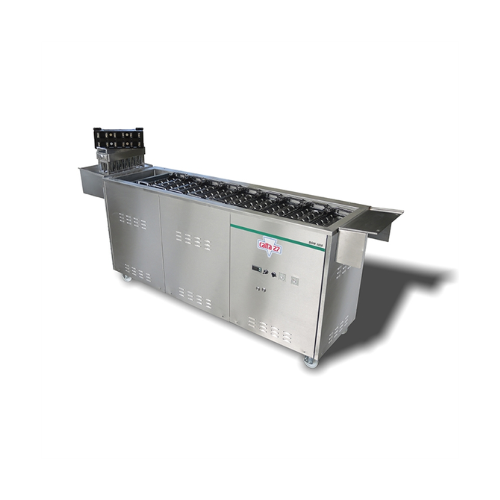

Hardening tank for water-ice lollies

Enhance your small-scale ice cream production with a versatile solution that allows you to efficiently harden and mold a variety of frozen treats, from stick ice creams to artisanal desserts, while optimizing freezing operations and reducing operational footprints.

Freezes and Molds Ice Creams and Confections

The BGM Hardening Tank from Catta 27 is ideal for small-scale ice cream and confectionery production. This versatile machine efficiently freezes and molds products such as stick ice-cream and candy bars. Available in two models, the BGM offers a processing capacity of up to 1,000 pieces per hour, with customizable options like a hot chocolate tank or a wrapping machine, optimizing your production line. With a refrigerant capacity that accommodates both batch and pilot operations, the tank integrates seamlessly into existing processes, ensuring consistent product quality. Air and water-cooled options allow for efficient energy use, while the compact design facilitates space-saving installations. With HACCP compliance and durable construction, the BGM ensures food safety and longevity, backed by Catta 27’s engineering support for tailored solutions.

Benefits

- Enhances production efficiency by processing up to 1,000 pieces per hour.

- Customizable options allow for tailored operations, improving product innovation and flexibility.

- Minimizes energy use with air and water-cooled models.

- Easy integration into existing lines due to compact design and adaptability.

- Ensures durability and meeting food safety standards with HACCP compliance.

- Applications

- Lollies, Sweets, Candy bars, Desserts, Ice creams

- End products

- Tartufo, Water-ice lolly, Stick ice-cream, Water-ice push-up, Sandwich ice-cream, Bon bons, Cakes, Extruded stick ice-cream

- Steps before

- Mix Treatment, Batch Processing, HTST Processing, Emulsification

- Steps after

- Hot Chocolate Coating, Wrapping, Packing

- Input ingredients

- ice cream base, water-ice mix, stick

- Output ingredients

- ice cream on a stick, water-ice lolly

- Market info

- Catta 27 is known for manufacturing high-quality engineered-to-order (ETO) industrial equipment, specializing in customized solutions for various industries. Renowned for innovation and reliability, Catta 27 delivers precise, tailored machinery to meet complex client specifications efficiently.

- Hourly Production

- Up to 500 pz/h

- Refrigerant Capacity Tank

- 68 l

- Refrigerant Capacity Freeze

- 12 l

- Total Installed Power

- 6.4 kW

- Condenser

- Air

- Condensing Water Consumption

- 250 l/h

- Weight

- 330 kg

- Dimensions

- 1320 x 630 x 1020 mm

- Hourly Production

- Up to 1000 pz/h

- Refrigerant Capacity Tank

- 120 l

- Refrigerant Capacity Freeze

- 12 l

- Total Installed Power

- 12.2 kW

- Condenser

- No

- Condensing Water Consumption

- 920 l/h

- Weight

- 495 kg

- Dimensions

- 2120 x 630 x 1020 mm

- Hourly Production Capacity

- Up to 1, 000 pieces per hour

- Automation Level

- Semi-Automatic

- Cooling Mechanism

- Air/Water Cooled

- Customization Options

- Hot chocolate tank, Small wrapping machine

- Mold Flexibility

- Available in multiple models

- Refrigerant Capacity

- 68 to 120 liters

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 1320x630x1020 mm

- Machine footprint

- 2120x630x1020 mm

- Tank size

- Refrigerant Capacity

- Weight

- 330 kg / 495 kg

- Mold set availability

- Available in various models

- Customization Options

- Hot chocolate tank, small wrapping machine

- Air-cooled or Water-cooled

- Condenser Air / Water Consumption

- Model Options

- BGM with different hourly production rates

- Additional Features

- Hot chocolate tank

- Additional Features

- Small wrapping machine

- Mold Selection

- Custom molds available