Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and minimal product degradation with direct steam infusion, ideal for processing sensitive food and beverage formulations.

Heats, Cools, and Sterilizes Liquid Products

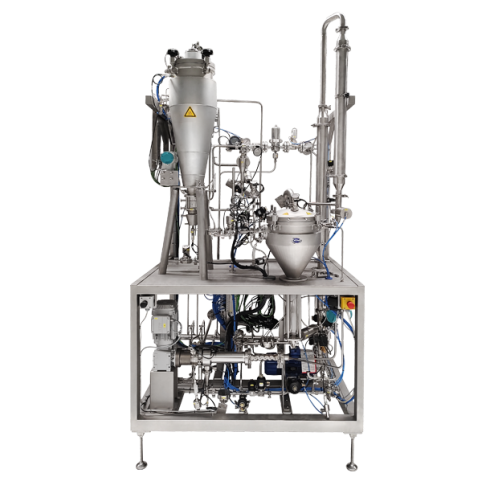

The HT324 Direct Steam Infusion & DSI System from OMVE is specifically engineered for those in the dairy, beverage, and food processing industries seeking robust solutions for heat treatment and sterilization of liquid products. This system combines Direct Steam Infusion and Steam Injection technologies, allowing for rapid heating and cooling profiles which preserve product quality by minimizing thermal degradation and achieving high spore kill rates. With nominal capacities of 100 or 200L/hr, the HT324 offers PLC-controlled operations, ensuring high levels of automation and process control. It’s designed for in-line and stand-alone operations, making it versatile for different production settings. Unique features include a 20-bar flash tank pump outlet pressure and a 0.2 bar(a) vacuum in the flash tank for maximum cooling efficiency. Additionally, the system integrates seamlessly with existing UHT pilot plants and includes automatic CIP/SIP systems for effective cleaning. Compliance with industry standards ensures reliable operation across a range of applications, from milk and yogurt to nutraceutical drinks and plant-based beverages.

Benefits

- Enhances product quality by minimizing thermal degradation during sterilization.

- Increases production flexibility with adjustable capacities of 100 or 200L/hr.

- Reduces energy consumption through efficient vacuum cooling in the flash tank.

- Simplifies maintenance and ensures process reliability with automatic CIP/SIP systems.

- Supports diverse product lines, from dairy to plant-based beverages, enhancing operational versatility.

- Applications

- Soups, Alcoholic drinks, Sauces, Nutraceuticals, Fats, Still drinks, Oils, Plant-based, Carbonated drinks, Ice creams, Dairy

- End products

- Protein shakes, Cheese, Beer, Orange soda, Almond milk, Vitamin-enriched drinks, Vanilla ice cream, Margarine, Yogurt, Olive oil, Tomato soup, Milk, Whiskey, Lemon-lime soda, Soy milk, Fruit sorbet, Lemonade, Ketchup, Iced tea, Mayonnaise, Chicken soup

- Steps before

- Deaeration, Homogenizing, MPV Blending and Mixing

- Steps after

- Cooling, Flash tank vacuum process, Packaging

- Input ingredients

- sensitive food products, dairy, fats, oils, carbonated drinks, still drinks, alcoholic drinks, soups, sauces, plant-based ingredients, nutraceuticals, ice creams

- Output ingredients

- sterilized food products, heat-treated products, minimized product degradation, products with high spore kill rate

- Market info

- OMVE is known for manufacturing pilot and small-scale processing equipment for the food and beverage industry, specializing in pasteurization, carbonation, fermentation, and homogenization systems, with a strong reputation for innovation and quality in engineered-to-order solutions.

- Capacity

- 100 or 200 L/hr

- Flash Tank Pump Outlet Pressure

- 20 bar

- Vacuum Pressure

- 0.2 bar(a)

- Holding Times

- Very Short

- Cooling Method

- Vacuum flash tank

- Automation

- High level of automation, control

- Working mechanism

- Steam Infusion, Injection

- Integrated steps

- In-Line Sterilization

- CIP/SIP

- Automatic CIP/SIP

- Batch vs. continuous operation

- In-Line Continuous

- Automation level

- High automation, control

- Cooling method

- Vacuum flash tank cooling

- Pump outlet pressure

- 20bar

- Vacuum pressure

- 0.2 bar(a)

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Spore kill rate

- High

- Tank size

- 100 or 200 L/hr

- Control panel type

- Stand-alone / HT320 system

- Control panel type

- Stand-alone / HT320 integrated

- Vacuum capability

- 0.2 bar(a)

- Flash tank pump outlet pressure

- 20 bar

- Capacity

- 100 or 200 L/hr