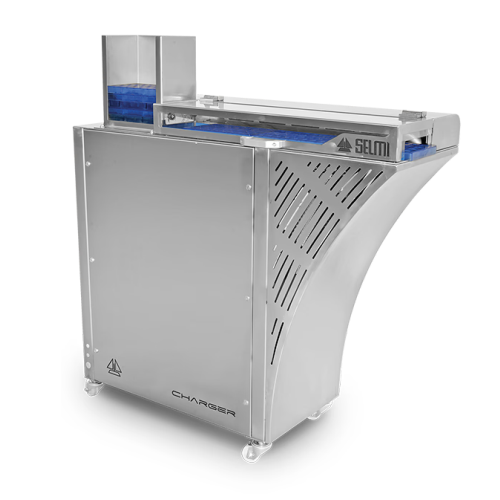

Automatic heated mould loader for chocolate production

Streamline your chocolate production with this heated mould loader that optimizes filling quality and efficiency by ensuring consistent mould temperature, perfect for creating complex chocolate confections with precision.

Heats and Loads Moulds for Chocolate Production

The Selmi Charger 175/275 is an automatic mould heater and loader specifically engineered for seamless integration with the TUTTUNO Oneshot chocolate production line. This equipment excels in maintaining optimal mould temperature through controlled hot air application, essential for achieving consistent chocolate filling quality. The Charger is designed to address the demands of chocolate manufacturers seeking enhanced precision in moulding and loading processes, making it invaluable across various applications, from pralines to ganache-filled bonbons and chocolate bars.

Utilizing a temperature-regulated hot air system, the Charger ensures that each mould is uniformly preheated, significantly reducing imperfections in the finished product. With a focus on automation and efficiency, it can easily integrate into existing operations, enhancing throughput without requiring additional electrical power supply, as it connects directly with the TUTTUNO system.

Ideal for food and confectionery industries, the Selmi Charger is constructed to handle continuous production cycles, supporting both solid and liquid product types. Its design facilitates easy cleaning and maintenance, minimizing downtime and maximizing operational reliability. The Charger is an optimal solution for those seeking to refine their chocolate production line while benefiting from Selmi’s comprehensive engineering support and customization options.

Benefits

- Enhances product quality by ensuring consistent mould temperature, reducing defects in filled chocolates.

- Increases production efficiency by seamlessly integrating into existing TUTTUNO Oneshot lines.

- Optimizes labor resources with automated mould loading, reducing manual intervention.

- Provides customizable heating controls for precise temperature management, catering to diverse chocolate products.

- Ensures long-term reliability and minimal maintenance, reducing downtime and associated costs.

- Applications

- Cocoa beans, Pralines, Ganache fillings, Coffee, Chocolate bars, Spreadable creams, Ice cream, Dried nuts, Hollow chocolate bodies, Chocolate, Anhydrous pastes, Truffles

- End products

- Hollow chocolate easter eggs, Chocolate truffles, Praline chocolates, Chocolate tablets, Artisan chocolate from cocoa beans, Nutella-style chocolate spreads, Chocolate bars with fillings, Ice cream with chocolate swirls, Almond butter, Roasted coffee beans, Ganache-filled bonbons

- Steps before

- Mould preparation, Ingredient mixing, Chocolate tempering

- Steps after

- Chocolate cooling, Mould demoulding, Chocolate packaging

- Input ingredients

- chocolate moulds, cold moulds

- Output ingredients

- pre-heated chocolate moulds, filled chocolate products

- Market info

- Selmi is renowned for manufacturing high-quality chocolate processing equipment, such as tempering, enrobing, and cooling machines, with a strong reputation for precision, innovation, and reliability in the confectionery and chocolate industry.

- Voltage

- 220V

- Phase

- Single Phase

- Frequency

- 50/60Hz

- Power Consumption

- 2kW

- Dimensions (Charger 175)

- H

- Dimensions (Charger 275)

- H

- Working Mechanism

- Automatic mould heating, loading

- Integrated Steps

- Mould heating and loading combined

- Automation Level

- PLC-controlled

- Batch vs. Continuous Operation

- Batch

- Changeover Time

- Minimal due to integrated system

- Cleaning Method

- Manual

- Energy Efficiency

- Utilizes existing power supply

- Air Incorporation Control

- Adjustable via control panel

- Abrasion resistance

- Suitable for materials that require gentle handling

- Biological compatibility

- Yes, compatible for food-grade materials

- Cleanability

- Designed for easy cleaning, suitable for food-grade environments

- Corrosive resistance (e.g. acids)

- Not applicable, designed for chocolate and similar non-corrosive materials

- Density/particle size

- Suitable for chocolate and ganache with varying viscosities

- Machine Footprint

- 1400mm x 1300mm x 520mm (Charger 175)

- Machine Footprint

- 1400mm x 1300mm x 620mm (Charger 275)

- Control Panel Type

- Regulated via TUTTUNO Oneshot control panel

- Discharge Method

- Automatic mould loading