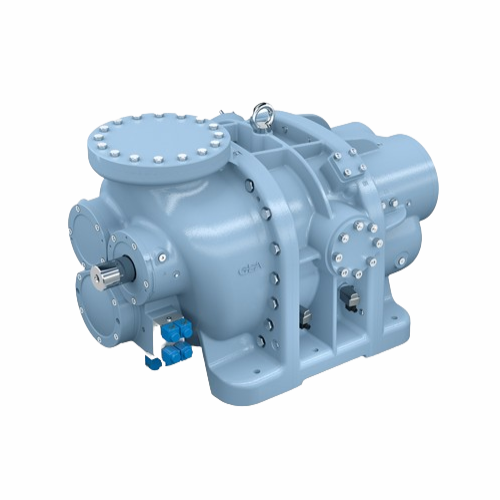

Industrial screw compressor for various refrigerants

Optimize your refrigeration systems with high-performance screw compressors designed for low noise and vibration, ensuring efficient compression and cooling under demanding conditions.

Compresses and Cools Industrial Refrigerants

The GEA Grasso LT Series Screw Compressor, designed by GEA, provides customizable solutions for industrial refrigeration challenges. This equipment features a robust compression mechanism tailored for applications in ammonia refrigeration, HVAC systems, and more. It efficiently handles refrigerants, supporting a variety of end-products such as vaccines, LNG, and ice cream. With a swept volume range of 805 to 11,467 m³/h and capability to operate at speeds between 1,500 and 4,500 rpm, it ensures optimal cooling capacities. Designed for continuous high-speed operations, it integrates seamlessly into production lines with API 619 and ISO 10440 standards compliance. The compressors also offer energy efficiency through optimized motor control, and components are crafted for durability and reduced maintenance. For enhanced integration, it includes advanced PLC control systems and supports remote monitoring, making it suitable for sectors like food, marine, and pharmaceuticals.

Benefits

- Minimizes operational noise and vibration for enhanced workplace safety.

- Supports a wide range of refrigerants, enabling versatile industrial applications.

- Reduces energy costs through optimized motor efficiency.

- Ensures long equipment lifespan, decreasing maintenance frequency and costs.

- Integrates easily into existing systems with compliance to industry standards.

- Applications

- Chemical processing, Oil and gas industry, Pharmaceutical cooling, Refrigerants, Food and beverage production, Ammonia refrigeration, Energy sector, Hvac systems, Industrial cooling, Marine refrigeration

- End products

- Freon, Lng, Ammonia, Vaccines, Frozen pizza, Ship cargo units cooling, Power plant cooling units, Processed chemicals, Petrochemicals, Ice cream, Soft drinks

- Steps before

- Cooling load calculation, Refrigerant selection, System design, Component assembly

- Steps after

- Cooling/heating distribution, Maintenance scheduling, Energy efficiency monitoring, System optimization

- Input ingredients

- R717 (ammonia), common refrigerants

- Output ingredients

- cooling capacity, heating capacity

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Swept Volume Range

- 805 to 11, 467 m³/h at 2, 940 rpm

- Speed Range

- 1, 500 – 3, 600 rpm (P and V to XH types)

- Speed Range

- 1, 500 – 4, 500 rpm (R, S, and T types)

- Design Pressure

- 28 bar, 52 bar

- Refrigerants Compatible

- R717 (ammonia) and all other common refrigerants

- Noise and Vibration Levels

- Low

- Standard Compliance

- API 619 and ISO 10440

- Working mechanism

- Screw compressor

- Swept volume

- 805 to 11, 467 m³/h

- Speed range

- 1, 500 – 4, 500 rpm

- Design pressure

- 28 bar, 52 bar

- Compressor types

- P, V, R, S, T to XH

- Refrigerant compatibility

- R717 (ammonia) and all common refrigerants

- Operational noise and vibration

- Low levels

- Automation level

- High availability

- Maintenance ease

- Easy

- Machine footprint

- N/A

- Material Type

- Steel, Aluminum

- Noise level

- Low noise

- Vibration levels

- Low vibration

- Shape and size

- Varies by type (16 sizes)

- Bearing Type

- Sleeve and roller bearing

- Control panel type

- Advanced digital interface

- Integration possibilities

- API 619, ISO 10440 compliance

- Speed range adaptation

- 1, 500 – 4, 500 rpm

- Refrigerant compatibility

- R717 and other common refrigerants

- Pressure rating customization

- 28 bar, 52 bar