Inline high shear mixing for dairy and condiments

Streamline your production line with innovative inline high shear mixing, ensuring seamless emulsification and homogenization for liquid and slurry products.

Mixes, Emulsifies, and Homogenizes Inline

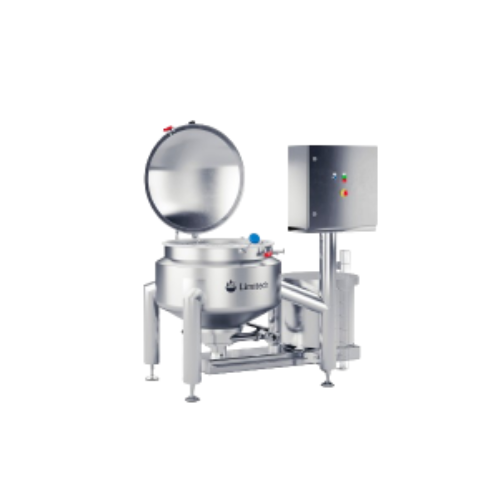

The SuperFlow 2 Inline from Limitech is an engineered inline high shear mixer tailored for food, beverage, dairy, and personal care industries. Featuring high shear inline mixing, this machine excels in emulsifying and homogenizing processes, optimizing the production of diverse products such as custard pudding, infant formula, and liquid foundation. With an emphasis on continuous operation, it handles both liquid and slurry product types efficiently. The SuperFlow 2 uses direct steam injection and vacuum technology to enhance processing capabilities and is integrated with a CIP system for effortless cleaning. Available in stainless steel to resist corrosion, it offers optional features like frequency inverters and customizable inlet numbers for tailored configurations. This mixer is designed to seamlessly integrate into your production line, improving consistency and throughput while maintaining compliance with industry standards.

Benefits

- Streamlines operations with continuous inline processing for consistent product quality.

- Enhances product texture and stability through precise high shear emulsification and homogenization.

- Minimizes cleaning time and contamination risk with integrated CIP system.

- Offers energy efficiency with optional frequency inverters for variable-speed mixing.

- Customizable design supports a wide range of application needs and production scales.

- Applications

- Beverages, Sauces, Personal care products, Pet food, Confectionery, Custard, Pharma products, Vegetable cream, Ice cream mix, Baby food, Vegan/plant-based products, Dairy products

- End products

- Flavored yogurt drink, Béchamel sauce, Non-dairy creamer, Canned dog food, Infant formula, Pharmaceutical suspension, Plant-based cheese, Custard pudding, Ice cream base, Chocolate ganache, Liquid foundation, Soy milk creamer

- Steps before

- Pre-mixing, Weighing

- Steps after

- Cooling, Packing

- Input ingredients

- dairy products, custard mix, flavoured milk, ice cream mix, pectine, recombined milk, vegetable cream, ingredients for emulsifying, ingredients for dissolving

- Output ingredients

- processed custard, flavoured milk product, ice cream base, dissolved pectine, recombined milk product, emulsified vegetable cream, homogenized products

- Market info

- Limitech is known for manufacturing customized food processing equipment, specializing in jacketed kettles and mixers for the food industry, focusing on flexibility and quality to meet client-specific requirements.

- High Shear Mixing

- Inline

- Vacuum

- Optional

- Direct Steam Injection

- Yes

- Inline Mixing

- Continuous

- Cleaning in Place (CIP)

- Standard

- Capacity

- Low to Medium Viscosity

- Cooling

- Optional

- Frequency Inverter on Mixer

- Optional

- Custom Number of Inlets

- Top, Bottom, or Side

- Direct Heating

- Optional

- Indirect Heating

- Optional

- Water Inlet

- On top

- Manway Hatch

- Standard

- Working mechanism

- High shear inline mixing

- Integrated steps

- Mixing, Dispersion, Dissolving, Emulsifying

- CIP principles

- CIP

- Batch vs continuous operation

- Inline Continuous

- Direct steam injection

- Yes

- Vacuum functionality

- Optional

- Cooling capability

- Optional

- Heating options

- Direct and Indirect heating

- Frequency control

- Optional via frequency inverter

- Custom inlet configuration

- Top, bottom or side

- Tank shape

- Cylindrical

- Feed/discharge method

- Inline

- Manway hatch

- Top

- Water inlet

- Top

- Customization options

- Custom inlets, Funnels, Insulation

- Control Panel Type

- HMI / PLC

- Integration Possibilities

- SCADA

- Frequency Inverter on Mixer

- Yes

- Custom Number of Inlets

- Top / Bottom / Side

- Insulation

- Available

- Heating Options

- Direct / Indirect

- Cooling System

- Available

- Vacuum

- Available

- Funnels

- Available