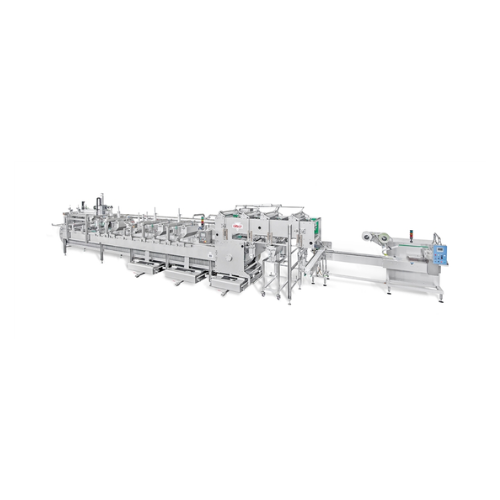

Linear mould system for ice cream production

Optimize your ice cream line with modular flexibility, allowing seamless adaptation to diverse product designs and production capacities.

Shapes and Hardens Ice Cream and Desserts

The Eskimoline series from Catta 27 offers versatile Linear Mould Machines tailored for ice cream and dessert production. These machines stand out for their modular design, enabling seamless integration into existing production lines with flexibility for various product shapes and capacities. Utilizing a customizable moulding and hardening process, the Eskimoline excels in producing high-quality extruded popsicles, chocolate-covered bars, and layered cakes, supporting processing capacities ranging from 7,500 to 28,000 pieces per hour. Each unit is equipped with PLC control for optimal automation, while energy efficiency is improved through advanced refrigerant options like FREON and NH3. Constructed with durable materials, the machines ensure compliance with food industry standards and feature easy maintenance access, supporting continuous, high-speed production demands.

Benefits

- Enhances production efficiency with modular configuration for tailored product shaping.

- Reduces operational costs through energy-efficient cooling with FREON and NH3 refrigerants.

- Increases throughput with capabilities up to 28,000 pieces per hour.

- Simplifies integration into existing lines, minimizing setup time.

- Ensures consistent product quality with precise moulding and hardening controls.

- Applications

- Stick ice-cream, Water-ice lolly, Sandwich, Tartufo, Candy bars, Desserts, Cakes, Ice cream, Bon bons

- End products

- Gourmet ice cream sundaes, Vanilla ball cones with toppings, Candy bars with nougat and caramel layers, Extruded ice cream popsicles, Ice cream sandwiches with caramel layers, Bon bons with chocolate coating, Chocolate covered ice cream bars, Layered ice cream cakes with nuts, Tartufo with chocolate core, Fruit-flavored water ice push-ups

- Steps before

- Mix Treatment, Freezing, Batch Preparation, Dosing

- Steps after

- Hardening, Extrusion, Packaging, Cooling

- Input ingredients

- ice cream mix, water, air

- Output ingredients

- ice cream, extruded stick ice-cream, lollies, water-ice lolly, water-ice push-up, extruded products, sandwiches, bon bons, candy bars, cakes, tartufo, desserts

- Market info

- Catta 27 is known for manufacturing high-quality engineered-to-order (ETO) industrial equipment, specializing in customized solutions for various industries. Renowned for innovation and reliability, Catta 27 delivers precise, tailored machinery to meet complex client specifications efficiently.

- Pieces Per Hour

- 7, 500/12, 000

- Number of Rows

- 5-6-8

- Air Consumption

- 11, 000 Nl/min

- Water Consumption

- 4, 000 l/min

- Total Installed Power

- 28.5 kW

- Cooling Power

- 60-100 kW

- Type Of Refrigerant

- FREON - NH3

- Dimensions

- 12, 000x1, 900x2, 200 mm

- Pieces Per Hour

- 15, 000/21, 000

- Number of Rows

- 10-12-14

- Air Consumption

- 3, 600 Nl/min

- Water Consumption

- 7, 000 l/min

- Total Installed Power

- 38 kW

- Cooling Power

- 90 kW

- Dimensions

- 15, 600x3, 950x2, 950 mm

- Pieces Per Hour

- 21, 000/28, 000

- Number of Rows

- 14-16-18

- Air Consumption

- 17, 000 Nl/min

- Water Consumption

- 10, 000 l/min

- Total Installed Power

- 94.4 kW

- Cooling Power

- 180-240 kW

- Dimensions

- 12, 000x2, 750x2, 200 mm

- Production rate

- 7500–28000 pieces/hour

- Modularity

- Customizable stations

- Flexibility

- Wide variety of products

- Adaptability

- Layout configurability

- Cooling system

- Freon / NH3

- Row configuration

- 5–18 rows

- Cooling power

- 60–240 kW

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 12, 000x1, 900x2, 200 mm (Eskimoline 5)

- Machine footprint

- 15, 600x3, 950x2, 950 mm (Eskimoline 10)

- Machine footprint

- 12, 000x2, 750x2, 200 mm (Eskimoline 14)

- Modularity

- Yes, stations are modular

- Shape

- Adaptable to production layout

- Cooling method

- FREON - NH3

- Control panel type

- PLC / Manual

- Modular design

- Yes

- Production layout adaptability

- Yes

- Cooling option

- FREON / NH3

- Row configuration

- 5-6-8 / 10-12-14 / 14-16-18