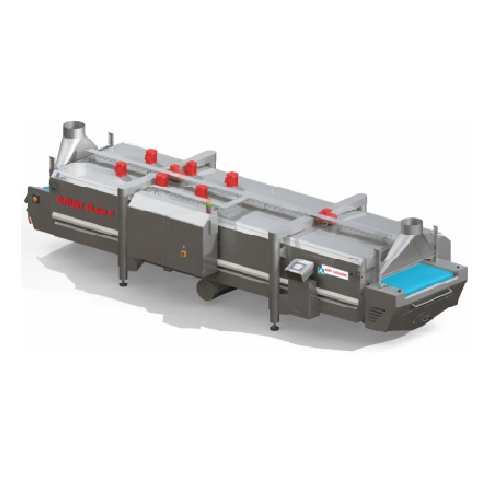

Cryogenic freezing tunnel for crust-freezing delicate foods

Enhance your production with rapid crust-freezing, expertly preserving the shape and appearance of delicate food products while maintaining high-speed continuous operations.

Freezes and Crust-Freezes Soft Food Products

The Cryogenic Tunnel Freezer – CFP from The SERAP Group is engineered to deliver unmatched precision in crust-freezing soft and fragile food products. Utilizing a high-speed conveyor saturated with liquid nitrogen, it enables instant freezing, critical for protecting the structural integrity and appearance of products like ravioli, ice cream bars, and filled pasta shells. This tunnel offers versatility in freezing methods, allowing either immersion in a nitrogen bath or an overhead spray system. Ideal for food processing, confectionery, and ready meal industries, it seamlessly integrates into continuous production lines, effectively reducing deformation and product marking. Constructed from robust AISI 304 stainless steel, it is compliant with European standards and designed for enduring performance. Its energy-efficient design, developed in partnership with AIR LIQUIDE, ensures operational cost savings. The Cryogenic Tunnel Freezer – CFP can handle a variety of product types, both solid and liquid, enhancing your production capacity while maintaining quality. For maintenance ease, the equipment is designed with accessibility in mind, simplifying cleaning and reducing downtime. Custom configurations are available to meet specific throughput requirements and product specifications.

Benefits

- Preserves product integrity by preventing deformation and marking during the freezing process.

- Enhances operational efficiency with high-speed continuous processing capabilities.

- Lowers production costs through energy-efficient liquid nitrogen use.

- Adaptable to various production requirements with customizable freezing methods.

- Complies with European standards, ensuring reliable and safe food processing operations.

- Applications

- Mousses, Ready meals, Complex products, Pasta, Extruded biscuits, Fragile and soft foods, Ice cream

- End products

- Lasagna, Frozen lasagna, Ice cream bars, Filled pasta shells, Eclairs, Ravioli, Chocolate-covered ice cream pops, Frozen mousse desserts

- Steps before

- Mixing, Extruding, Molding, Preparing

- Steps after

- Coating, Topping, Packaging, Storage

- Input ingredients

- fragile foods, soft foods, extruded biscuits, pasta, mousses, ready meals, ice cream, complex products

- Output ingredients

- crust-frozen foods, preserved shape and appearance, defect-free coated products

- Market info

- Material

- AISI 304 stainless steel

- Automation

- Conveyor belt system

- Freezing method

- Liquid nitrogen bath/spray

- Compliance

- European standards

- Working mechanism

- Conveyor belt with liquid nitrogen saturation

- Integrated steps

- Crust-freezing, immersion, or spray of liquid nitrogen

- Batch vs. continuous operation

- Inline Continuous

- AISI 304 Stainless Steel Compatibility

- Yes

- Corrosion Resistance

- High

- Food Safety Compliance

- Compliant with European Standards

- Temperature Compatibility

- Suitable for Cryogenic Temperatures

- Cleanability

- Easy to Clean

- Food Type

- Extruded biscuits, pasta, mousses, ready meals, ice cream

- FDA compliance

- Yes

- Stainless steel material standard

- AISI 304

- Material

- AISI 304 stainless steel

- Compliance with standards

- European standards

- Footprint

- Tunnel design

- Discharge method

- Conveyor belt

- Control panel type

- Automation / Manual

- Integration with existing systems

- Yes

- Material

- AISI 304 stainless steel

- Configuration options

- Conventional freezing / Liquid nitrogen bath