Flexible depositor and extruder for small-scale production

Achieve precise multi-mass creations with a compact, versatile depositor and extruder, perfect for experimental lab environments and small-scale product lines, ensuring seamless transitions from concept to production.

Deposits and Extrudes Chocolate for Creative Production

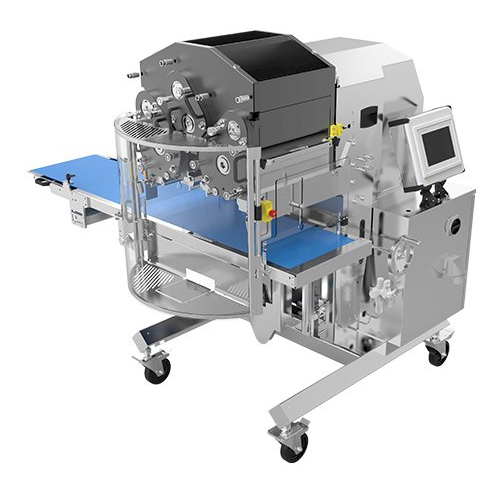

The Alice™ C-Frame from Aasted is a versatile depositor and extruder designed for the food, chocolate, bakery, and confectionery industries. Ideal for small-scale and continuous production, it empowers chocolate producers and R&D departments to experiment with up to three masses simultaneously. This plug-and-play machine offers seamless integration into laboratory environments, featuring a mobile design for flexible operation. The Alice™ C-Frame’s user-friendly interface ensures efficient use, making it an essential tool for developing innovative chocolate bars, filled chocolates, pralines, and more. With its ability to handle both liquid and solid product types, this equipment provides a dynamic solution for diverse applications.

Benefits

- Enhances creativity by allowing experimentation with multiple masses.

- Streamlines small-scale production with easy, plug-and-play setup.

- Improves operational flexibility with a mobile design.

- Facilitates product innovation in laboratory and R&D settings.

- Integrates seamlessly into existing production lines for efficient workflow.

- Applications

- Snacks, Bakery, Confectionery, Sweets, Chocolate

- End products

- Chocolate shells, Filled chocolates, Pralines, Decorative chocolate shapes, Molded confectionery items, Chocolate eggs, Enrobed pastries, Confectionery coatings, Snacks with chocolate coating, Chocolate bars, Chocolate lentils, Chocolate chips

- Steps before

- Mixing, Mass preparation

- Steps after

- Cooling, Enrobing, Packaging, Tempering, Quality assurance

- Input ingredients

- chocolate masses, bakery ingredients, confectionery ingredients, chocolate temper materials

- Output ingredients

- chocolate products, bakery products, confectionery products, chocolate chips, chocolate balls, lentils, eggs, shaped chocolate shells, enrobed products

- Market info

- Aasted is known for its expertise in manufacturing equipment for the chocolate, bakery, and confectionery industries, offering solutions like tempering, molding, and baking machinery with a strong reputation for innovation and quality.

- Capacity

- Small-scale production

- Mass handling

- Up to 3 different masses simultaneously

- Automation

- Plug-and-play

- Mobility

- Machine on wheels

- Cooling control

- Cooling simulator

- Enrobing precision

- Highly flexible and efficient

- Production Type

- Standalone or continuous production

- Temperature control

- AMC SuperNova Temper

- Flexibility

- Dynamic depositor and extruder

- Shell formation

- FrozenCone® cold pressing

- Enrobing disassembly

- No tools required

- Automation level

- Manual / Plug-and-play

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Quick setup

- Cleaning method

- Easy to disassemble / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Standalone, portable, compact

- Control panel type

- Plug-and-play interface

- Machine mobility

- On wheels

- Control panel type

- Touchscreen / Button controls

- Integration possibilities

- Standalone / Inline operation

- Flexibility

- Handles up to 3 different masses simultaneously

- Mobility

- On Wheels

- Configuration

- Plug-and-play