Continuous moulding line for chocolates

Achieve precise chocolate moulding with continuous operation, ensuring high-speed production of diverse confectionery forms, from pralines to aerated pieces, with optimal quality and uniform gloss.

Processes and Moulds Diverse Chocolate Products

The ChocoMaster Continuous Moulding Line from Bühler Group is a highly flexible moulding solution designed to optimize chocolate production. This system utilizes a servomotor-driven chain process to continuously and accurately deposit and mould chocolate into various forms, such as pralines, bars, and aerated pieces. Its modular design includes integrated tempering, cooling, and demoulding stages, ensuring consistent quality and finish. Suitable for high-speed operations, it manages both liquid and solid chocolate products, with the ability to seamlessly switch between different styles, including filled and chocolate-coated snacks. Built with noncorrosive materials for hygiene, the ChocoMaster also allows customization to meet specific manufacturing requirements, supported by Bühler’s global engineering expertise. Automated control ensures smooth integration with existing confectionery lines, optimizing throughput and minimizing downtime.

Benefits

- Enhances production flexibility with seamless switching between diverse chocolate products.

- Ensures consistent product quality and gloss through uniform tempering processes.

- Minimizes maintenance downtime with a hygienic design using noncorrosive materials.

- Improves operational efficiency using servomotor-driven systems for smooth mould movement.

- Customizable to specific manufacturing needs, supported by expert engineering support.

- Applications

- Snacks, Confectionery, Bars, Tablets, Chocolate

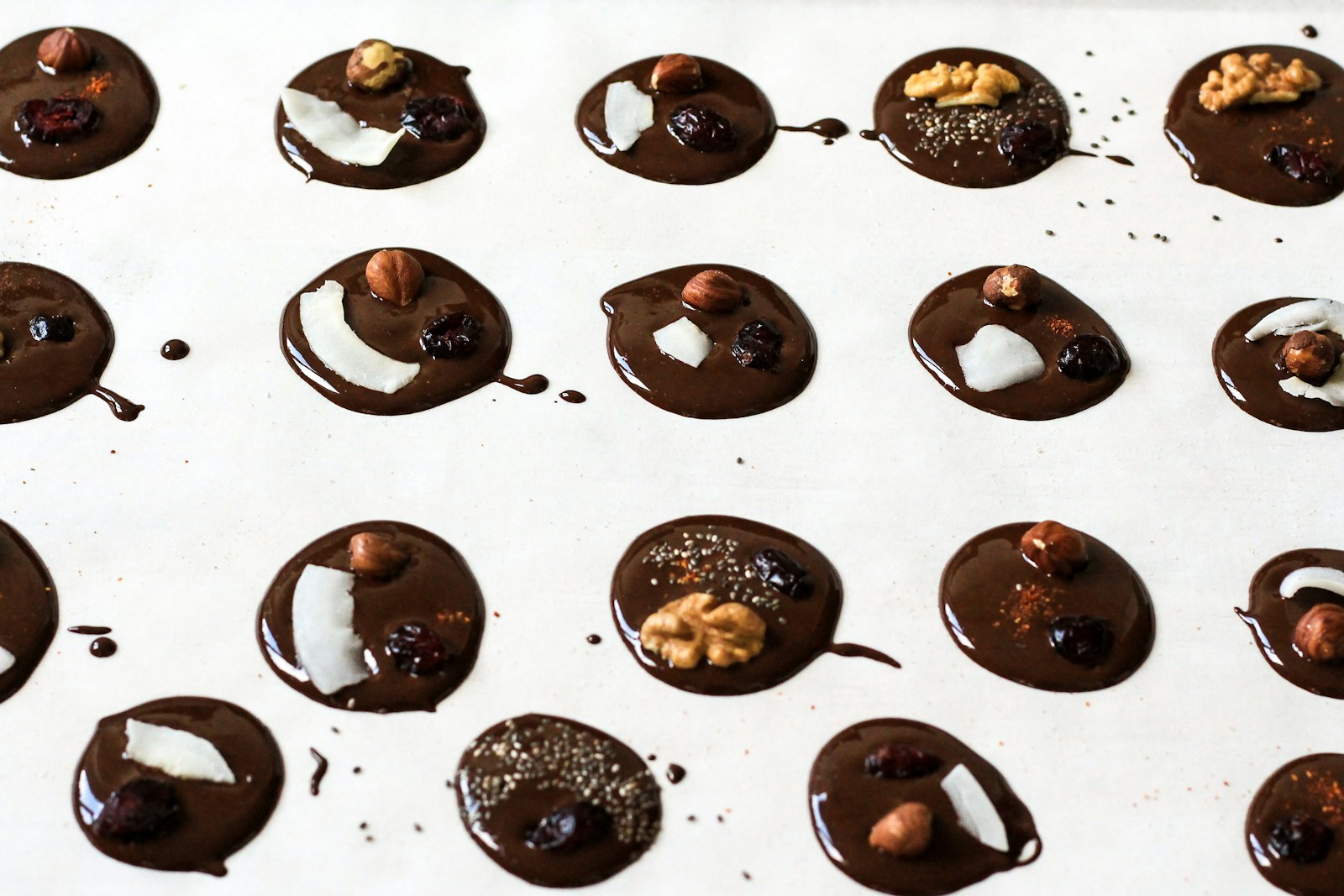

- End products

- Filled chocolate bars, Dark chocolate tablets, Chocolate pralines, Encased chocolate snacks, Chocolate tablets with inclusions, Aerated chocolate pieces, Chocolate drops, Milk chocolate bars, Chocolate-coated nuts

- Steps before

- Tempering, Mixing, Cooking, Conditioning

- Steps after

- Cooling, Packing, Palettizing, Sorting

- Input ingredients

- chocolate mass, inclusions

- Output ingredients

- moulded chocolates, chocolate bars, chocolate tablets, aerated chocolates

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Automation

- PLC-controlled

- Filling accuracy

- ±0.5%

- Filling volume

- 1 ml – 5 L

- Capacity

- Variable throughput

- Material

- Noncorrosive

- Tempering

- Uniform

- Precision depositing

- High-precision

- Motion control

- Servomotors

- Molding line movement

- Continuous

- Product compatibility

- Spot, ribbon, one-shot

- Production style

- Continuous production

- Working Mechanism

- Continuous Moulding

- Integrated Steps

- Spot, Ribbon, One-shot Depositing

- CIP Principles

- Hygiene Design with Noncorrosive Materials

- Batch vs Continuous Operation

- Continuous

- Changeover Time

- High Flexibility for Product Change

- Corrosive resistance (e.g. acids)

- Noncorrosive materials

- Machine footprint

- Compact design

- Material used

- Noncorrosive materials

- Mould design

- Continuous mould motion

- Control panel type

- Integrated PLC control panel

- Discharge method

- Automatic demoulding

- Deposition type

- Spot, ribbon, one-shot

- Modular design

- Tailored to process

- Control panel type

- High-precision depositing control

- Flexibility

- Switch between chocolate styles

- Integration possibilities

- Continuous production

- Customization

- Customized solutions tailored to process

- Hygiene design

- Noncorrosive materials