Chocolate tempering solution for industrial production

Achieve consistent chocolate crystallization with a machine that ensures optimal texture and shine in your confections, eliminating common tempering issues like bloom and poor texture.

Tempers Chocolate for Optimal Consistency and Quality

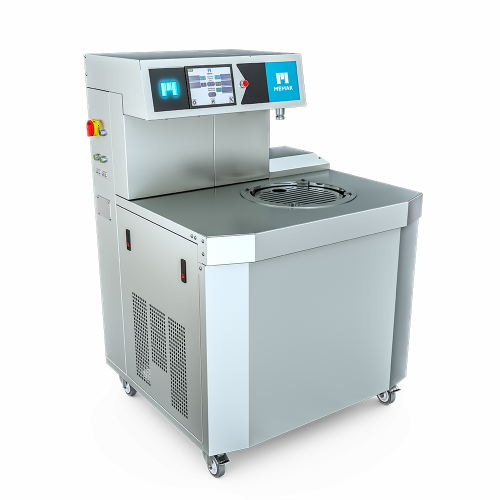

The MKTM-250 from Memak offers chocolate manufacturers a robust solution for achieving consistent tempering, essential for producing high-quality confectionery products. This tempering machine stabilizes chocolate crystals using precise heat treatment, ensuring the ideal texture and sheen in chocolates ranging from bars to truffles.

With a processing capacity of 250 kg per hour, the MKTM-250 suits both medium and large-scale operations. Its automated controls facilitate seamless integration into existing production lines, while its efficient power usage—totaling 8.2 kW—helps reduce operational costs.

Constructed with durable materials, this machine provides excellent corrosion resistance, extending its lifespan and maintaining hygiene standards. The MKTM-250 also supports easy cleaning and maintenance, minimizing downtime and ensuring smooth operation.

Designed to meet the stringent quality demands of the food, confectionery, and bakery industries, it underscores Memak’s commitment to engineering support and customizable options, resulting in bespoke solutions to match specific production needs.

Benefits

- Enhances product quality by ensuring consistent crystal structure in chocolates.

- Increases production efficiency with a capacity of 250 kg per hour.

- Reduces operational costs through optimized energy consumption of 8.2 kW.

- Minimizes downtime with easy-to-maintain design and cleaning processes.

- Integrates seamlessly into existing lines with automated control systems.

- Applications

- Candy, Confectionery products, Sweets, Bakery products, Chocolate

- End products

- Filled chocolates, Chocolate tablets, Molded chocolate figures, Pralines, Chocolate shells for confections, Chocolate coatings, Ganache, Chocolate bars, Chocolate chips, Truffles

- Steps before

- Fat Melting, Pre-Mixing, Grinding, Conching, Chocolate Storage

- Steps after

- Moulding, Enrobing, Cooling, Wrapping, Packing

- Input ingredients

- chocolate, untempered product

- Output ingredients

- tempered chocolate

- Market info

- Memak is known for manufacturing high-quality, engineered-to-order equipment primarily for the food processing industry, with a reputation for innovation, precision engineering, and reliable customer support.

- Product Code

- MKTM-250

- Capacity

- 250 kg/h

- Power of Mixer Motor

- 0.75 Kw

- Power of Resistance

- 4.5 Kw

- Total Power

- 8.2 Kw

- Working mechanism

- Heat treatment for chocolate tempering

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Batch

- Energy efficiency

- 8.2 kWh total power

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Food Safety Standards

- HACCP

- Machine footprint

- Compact design

- Tank shape and size

- 1650-3 Automatic Pre-Mixer System

- Discharge method

- Continuous discharge

- Control panel type

- Touchscreen interface

- Compact footprint

- Space-saving design