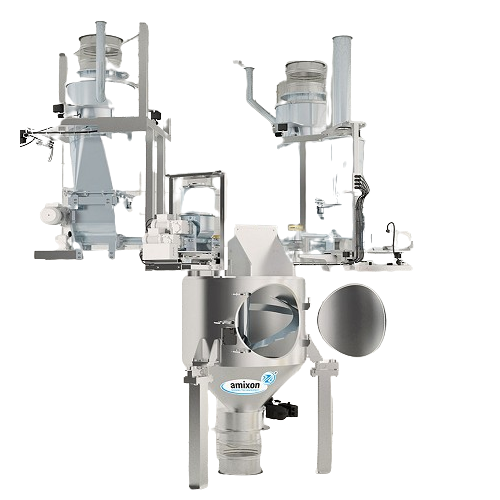

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a continuous powder mixer tailored for dry, moist, and suspended goods, ensuring seamless integration into your production line for optimal efficiency and product quality.

Mixes and Homogenizes Dry and Moist Goods

The Continuous Mixer (AMK) by amixon® offers a solution for efficiently blending various powder forms, from dry to moist and suspended goods. This mixer features a unique design with adjustable mixing intensity, allowing for seamless processing transitions from gentle homogenization to intensive deagglomeration. It supports applications across multiple sectors, including food, pharmaceuticals, and chemical industries, creating products such as baby formula powder, skincare cream, and polymer granules. The AMK mixer operates continuously with a capacity to maintain consistent output, ensuring no product loss at production start or end. This equipment integrates smoothly into production lines, offering extended processes like moistening, tempering, and reaction processing. With a top-mounted mixing device, it provides a hygienic solution meeting GMP, FDA, and 3-A Sanitary Standards, with easy cleaning options either dry or wet. Additionally, its capability for precise micro-fine liquid admixture enhances formulation accuracy, making it indispensable for high-volume production environments.

Benefits

- Optimizes production efficiency with customizable mixing intensity for various product types.

- Minimizes material waste by ensuring no product loss during startup and shutdown processes.

- Supports stringent hygiene standards, enhancing safety and compliance in sensitive manufacturing environments.

- Enhances product quality by achieving uniform mixtures, reducing batch inconsistencies.

- Integrates seamlessly into automated systems, allowing for continuous processing and reduced manual intervention.

- Applications

- Food, Powder metallurgy, Feed, Nutritional supplements, Infant formula, Fine ceramics, Plant-based food, Chemical industry, Hygiene and cosmetics, 3d printing, Herbs, Household detergents, Spices, Plastics, Pharmaceuticals

- End products

- Protein supplements powder, Spice blends, Herb extracts, Cornflakes, Baby formula powder, Vitamin c tablets, Polymer granules, Ceramic powder, 3d printing filament, Plant-based protein powder, Laundry powder detergent, Granola, Pain relief capsules, Skin care cream

- Steps before

- Purification, Grinding, Emulsification

- Steps after

- Sterilization, Packing, Drying, Tempering, Reaction processing

- Input ingredients

- dry goods, moist goods, suspended goods, liquid material

- Output ingredients

- homogenized mixture, deagglomerated material, processed goods

- Market info

- Amixon is renowned for designing and manufacturing high-quality mixing equipment, including powder mixers and vacuum dryers, for various industries such as food, pharmaceuticals, and chemicals, with a focus on precision, hygiene, and innovative mixing solutions.

- Mixing quality

- Technically ideal

- Mixing intensity

- Adjustable (gentle to intensive)

- Filling Level Selection

- 10% to 80% of cubic capacity

- Product Operation

- Batch or continuous

- Micro-fine admixture

- Without contamination

- Emptying of residues

- Ideal emptying

- Process Capabilities

- Moistening, tempering, drying, reaction processing

- Working mechanism

- Continuous mixing with boiler flow

- Batch vs. continuous operation

- Batch / Continuous options

- Integrated steps

- Moistening, tempering, drying, reaction processing

- Cleaning method

- Safe cleaning

- Dry or wet

- Mixing intensity adjustment

- Gentle homogenization to intensive deagglomeration

- Specific filling level selection

- 10% to 80% of capacity

- Micro-fine admixture of liquid

- Without contamination

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Tank shape and size

- Mounted only on top, fills to 80% capacity

- Feed/discharge method

- Continuous boiler flow, discharge device opens at 80% capacity

- Specific filling level

- 10% to 80% of cubic capacity

- Control panel type

- Automated for synchronization

- Mixing intensity adjustment

- Gentle homogenization to intensive deagglomeration

- Operation mode

- Batch or continuous

- Specific filling level selection

- 10% to 80% of cubic capacity

- Micro-fine liquid admixture

- Without contamination

- Cleaning options

- Dry or wet

- Compliance with standards

- GMP, FDA, 3-A Sanitary Standards, EHEDG