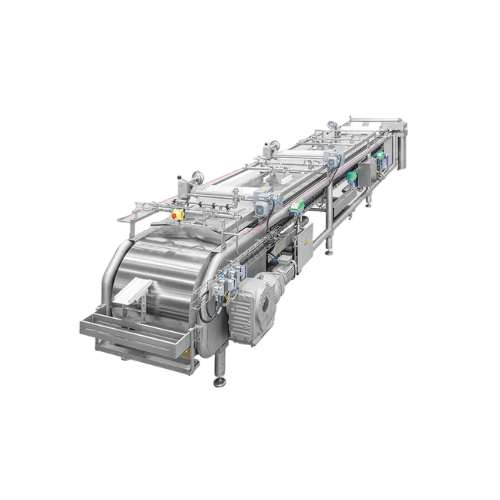

Industrial chocolate tempering belt

Achieve precise mass tempering for diverse confectionery textures with a stainless-steel belt that ensures uniform spreading and folding, streamlining your production line for optimal texture consistency.

Tempers and Conditions Confectionery Products

The Tempering Belt from CHOCOTECH is engineered for high-speed tempering of confectionery products like chocolate bars and gummy bears. This system integrates a tubular skid design with an advanced water tempering module to ensure precise temperature control. The direct-drive stainless-steel belt, available in various widths, facilitates seamless integration into continuous operations, while VFD-controlled mechanisms ensure process flexibility. The equipment features power-driven calibrating rollers and specially designed mass ploughs, enabling gentle spreading and folding for consistent product conditioning. Suitable for confectionery manufacturers and chocolate producers, it operates efficiently across solid and liquid product types. Additionally, the system supports easy cleaning and maintenance, optimizing uptime in food and chocolate production environments.

Benefits

- Enhances product consistency, ensuring high-quality confectionery results.

- Reduces energy consumption with variable frequency drive control.

- Allows seamless integration with existing production lines for efficient operation.

- Minimizes downtime with easy cleaning and maintenance protocols.

- Supports versatile application across a broad range of confectionery products.

- Applications

- Jelly, Fondant, Sweets, Hard candy, Chewy candy, Chocolate, Caramel

- End products

- Gummy bears, Soft toffees, Chocolate bars, Caramel chew, Lollipops, Chocolate fondant

- Steps before

- Weighing, Dissolving, Cooking, Vacuuming, Caramelization, Crystallization, Aeration, Cooling

- Steps after

- Metering, Forming

- Input ingredients

- chocolate mass, raw candy ingredients

- Output ingredients

- tempered chocolate, tempered confectionery mass

- Market info

- CHOCOTECH is known for providing innovative solutions in the confectionery industry, specializing in machinery for processing and manufacturing chocolate, candies, and other sweets, with a reputation for precision engineering and tailored, high-quality equipment solutions.

- Material

- Stainless steel

- Drive Type

- Direct drive

- Control Type

- VFD controlled

- Width

- Various widths available

- Tempering Zones

- Multiple zones available

- Integration

- Integrated water tempering system

- Design

- Tubular skid, hygienically designed

- Calibrating Rollers

- Power-driven

- Mass Processing

- Spreading and folding by special designed ploughs

- Working mechanism

- Direct drive with VFD control

- Integrated steps

- Calibrating rollers and mass ploughs for spreading and folding

- CIP/SIP

- Integrated water tempering system

- Batch vs. continuous operation

- Multiple tempering zones

- Corrosive resistance (e.g. acids)

- Stainless steel

- Machine footprint

- Compact tubular skid

- Material

- Stainless steel

- Discharge method

- Power-driven calibrating rollers

- Belt Width

- Various widths available

- Drive system

- Direct drive with VFD control

- Control panel type

- VFD Controlled

- Tempering zones

- Multiple options available

- Belt width

- Various widths available

- Integration possibilities

- Water tempering system integration