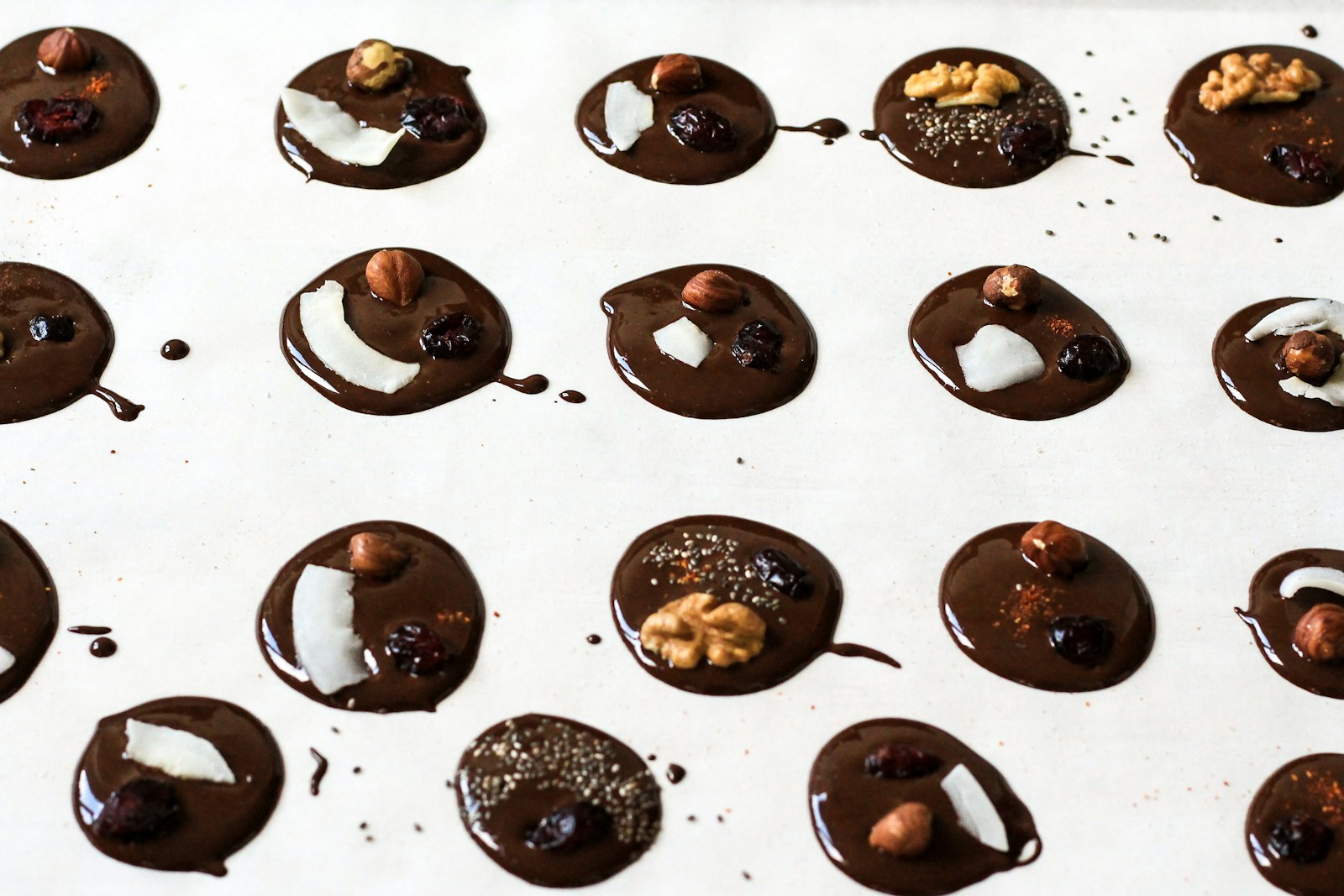

Chocolate drops production system

Create perfectly uniform chocolate drops with precision dispensing and seamless integration into your production line, enhancing consistency and quality in your confectionery offerings.

Produces Uniform Chocolate Drops

The Drops System from Selmi Group is an engineered-to-order chocolate production solution designed to enhance precision and efficiency in crafting uniform chocolate drops. Utilizing a pneumatic three-way valve, it ensures precise and adjustable casting directly onto a 300mm or 400mm cooling tunnel belt. Compatible with Selmi’s TOP EX tempering machines, it supports seamless integration into your existing line, facilitating automated, continuous production of various chocolate end-products. With a compact design, the equipment operates at electrical specifications of 220 V single phase and requires a compressed air source. The Drops System is ideal for chocolate manufacturers, confectionery producers, and gourmet chocolate makers who demand reliability and productivity in creating high-quality chocolate drops. Additionally, it interfaces with the cooling tunnel’s touch screen for easy operation and configuration, offering a streamlined and user-friendly experience.

Benefits

- Enhances production efficiency by integrating seamless chocolate drop casting into your existing line.

- Minimizes operational costs through precise, automated control and reduced material wastage.

- Supports product uniformity, ensuring consistent quality for high-end confectionery applications.

- Reduces manual intervention with integration capabilities via touch screen operation.

- Facilitates a broad range of chocolate products, enhancing product versatility and market reach.

- Applications

- Cocoa products, Snacks, Confectionery, Sweets, Spreadable creams, Chocolate bars, Chocolate, Truffles

- End products

- Chocolate sprinkles, Chocolate ganache squares, Hollow chocolate figures, Chocolate-covered nuts, Chocolate-coated bars, Ganache-filled chocolates, Chocolate drops, Chocolate enrobed snacks, Chocolate enrobed truffles, Chocolate-covered cereals

- Steps before

- Tempering, Cooling

- Steps after

- Cooling, Packing

- Input ingredients

- chocolate

- Output ingredients

- chocolate drops

- Market info

- Selmi is renowned for manufacturing high-quality chocolate processing equipment, such as tempering, enrobing, and cooling machines, with a strong reputation for precision, innovation, and reliability in the confectionery and chocolate industry.

- Electrical specification

- 220 V single phase - 50/60 Hz

- Power required

- 1.4 Kw - 16 A - 3 poles

- Dimensions

- 1200x1260x1565 mm (LxWxH)

- Compressed Air Usage

- 80 lt/min - 6 bars minimum - filtered, dried, de-oiled

- Automation

- Equipped with pneumatic three-way valve for precise and adjustable casting

- Batch size

- Minimum of 2 g per drop

- Injection technology

- Automated injection plate extraction

- Interfacing

- Touch screen display of the tunnel

- Tunnel belt compatibility

- 300 mm or 400 mm

- Working mechanism

- Injection on tunnel belt

- Integrated steps

- Injection and cooling

- Automation level

- Automated with touch screen interface

- Batch vs. continuous operation

- Continuous

- Precision control

- Three-way valve for precise dispensing

- Command interface

- Cooling tunnel touch screen

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Production size

- Minimum 2 g per drop

- Tunnel belt width

- 300 mm or 400 mm

- Compact footprint

- 1200x1260x1565 mm

- Control panel type

- Touch screen display on tunnel

- Discharge method

- Direct injection onto tunnel belt

- Control panel type

- Touch screen display

- Integration possibilities

- Compatible with Tunnel 300/400 mm and TOP EX tempering machine

- Pneumatic system

- Three-way valve for precise dispensing

- Automated injection

- Automated injection plate extraction