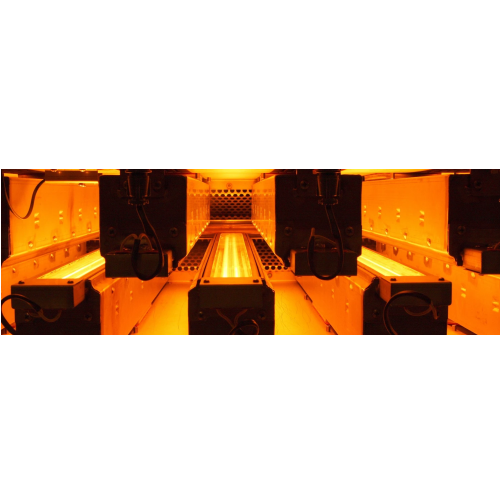

Infrared dryers and ovens for coating and substrate processing

Achieve precise drying and curing with customizable infrared solutions, enhancing product quality through optimized wavelength and control in pre- and post-production stages.

Dries, Preheats, Tempers, and Cures Materials

Dürr’s Infrared Dryers and Ovens offer versatile solutions across various industries, from automotive to woodworking. Utilizing precise control over infrared wavelengths, these systems excel in drying, preheating, tempering, and curing processes. Equipped with customizable features, including horizontal, vertical, or arched designs, they integrate seamlessly into your production line. Available with both gas-fired and electric options, these dryers and ovens are energy-efficient, reducing consumption by leveraging optimized motor controls. They enhance processing capacities through continuous, high-speed operations while accommodating both solid and liquid products. With the ability to combine infrared with flotation and impingement systems, this equipment ensures maximum drying effectiveness, tailored to your spatial and product requirements. Whether used for coating materials on mechanical components or preparing pharmaceutical products, Dürr provides engineered-to-order configurations and engineering support, ensuring compliance with industry standards and facilitating integration into existing facilities.

Benefits

- Enhances production efficiency by integrating seamless drying, preheating, and curing processes.

- Saves energy costs with optimized infrared wavelength control for precise temperature management.

- Customizable layouts ensure space optimization and fit into existing systems without major overhauls.

- Reduces operational downtime with configurations that support continuous, high-speed processing.

- Accommodates versatile applications across industries, broadening the scope of product treatment and preparation.

- Applications

- Chemicals, Pharmaceuticals, Wood products, Coating materials, Mechanical components, Automotive parts

- End products

- Steps before

- Coating, Preheating, Pre-drying

- Steps after

- Tempering, Fusing, Curing, Profiling

- Input ingredients

- coatings, substrates, chemicals, materials for drying, materials for curing, materials for tempering, materials for fusing, materials for preheating

- Output ingredients

- dried products, preheated products, tempered products, fused products, cured products, profiled products, processed substrates

- Market info

- Dürr is known for its expertise in industrial engineering and manufacturing solutions, specializing in automotive painting technology, environmental technology, and production efficiency systems. It has a strong reputation for innovation and quality in engineered-to-order equipment.

- Infrared wavelength

- Optimized for specific processes

- System configuration

- Horizontal, vertical, or arched layouts

- Integration capability

- Combines with flotation and/or impingement systems

- Heating type

- Gas-fired or electric IR

- Process control

- Optimized control system for precise conditions

- Customizability

- Tailored to specific product and spatial requirements

- Application

- Drying, preheating, tempering, fusing, curing, profiling

- Conveyor type

- Roll support or belt conveyor

- Working mechanism

- Infrared heating

- Integrated steps

- Drying, preheating, curing

- Automation level

- Automated control system

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- Variable based on configuration

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Yes/No

- Product type compatibility

- Preheating / Tempering / Curing

- Substrate type

- Coating / Profiling

- Layout configuration

- Horizontal / Vertical / Arched

- Energy source

- Gas-fired / Electric

- Machine layout

- Horizontal / Vertical / Arched

- Heating method

- Gas-fired / Electric IR

- Support type

- Roll / Belt conveyor

- Customization options

- Tailored for specific product and spatial requirements

- System integration

- Flotation / Impingement drying systems

- Layout configuration

- Horizontal / Vertical / Arched

- Infrared configuration

- Gas-fired / Electric

- Integration possibilities

- Flotation / Impingement drying systems