Continuous caramel cooker for candy production

Achieve perfect caramel consistency with precise control as this solution combines cooking and caramelization in a seamless, continuous process, ensuring uniformity and efficiency vital for confectionery production.

Simultaneously Cooks and Caramelizes Confectionery Mixes

The YPP® Continuous Caramel Cooker by CHOCOTECH GmbH is a precision-engineered solution for confectionery manufacturers seeking to streamline caramel production. This innovative cooker combines cooking and caramelization in a seamless flow, using a multi-stage process that ensures a homogeneous and well-emulsified caramel mass. Its dual counter stirrers enhance emulsification, producing a smooth, creamy texture ideal for various sweet applications, including caramel chews and sauces.

Capable of processing between 200 to 1200 kg/h, the YPP® adapts to multiple recipes and production demands, ensuring high throughput without sacrificing quality. The cooker integrates easily into existing production lines, providing efficient automation with its PLC-controlled operation and optional remote monitoring capabilities.

The energy-efficient design of the YPP® employs multiple steam jackets within a specially engineered tank, optimizing heat distribution, and reducing energy consumption. Fabricated from corrosion-resistant materials, the cooker ensures long-lasting performance and compatibility with diverse culinary substances.

Compliant with industry standards, the YPP® supports clean-in-place systems for effective, contamination-free maintenance, reinforcing the high hygiene standards required in confectionery production. CHOCOTECH offers tailored engineering support to customize the cooker’s specifications, ensuring an optimal fit for your production environment and specific confectionery needs.

Benefits

- Ensures consistent product quality with simultaneous cooking and caramelization.

- Increases production efficiency with high throughput capacities.

- Minimizes energy usage through optimized steam jacket design.

- Facilitates seamless integration into existing production lines with PLC controls.

- Simplifies maintenance with a built-in clean-in-place system.

- Applications

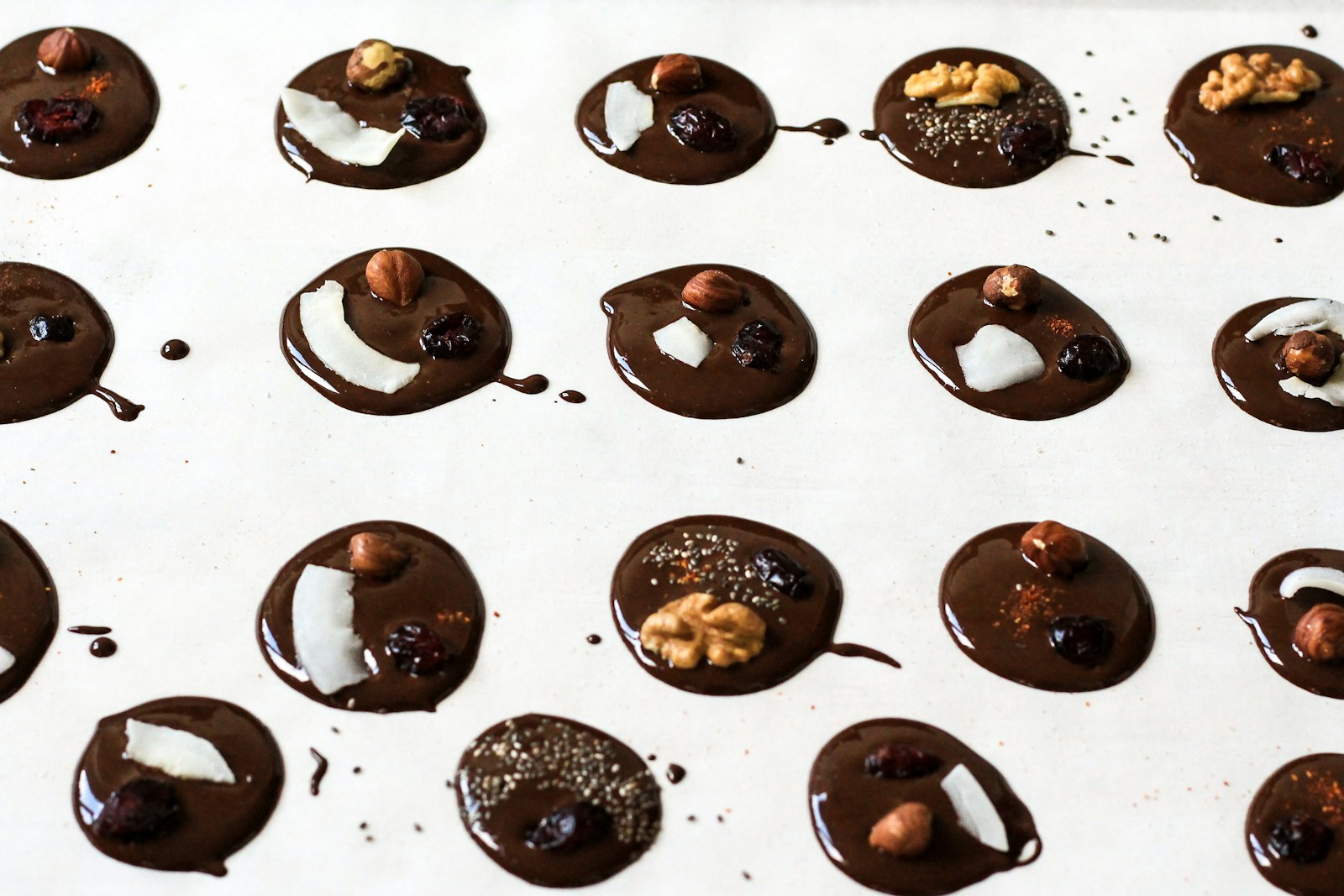

- Candy, Jelly, Brittle, Confectionery, Fondant, Sweets, Chewy candy, Hard candy, Chocolate, Caramel

- End products

- Gummy bears, Caramel sauce, Toffee, Jelly beans, Fondant icing, Caramel chews, Chocolate drops, Lollipops, Hard candy mints, Peanut brittle

- Steps before

- Weighing, Dissolving

- Steps after

- Vacuuming, Forming, Tempering, Cooling, Packing

- Input ingredients

- raw caramel mixture, raw ingredients

- Output ingredients

- homogeneous caramel mass, emulsified caramel

- Market info

- CHOCOTECH is known for providing innovative solutions in the confectionery industry, specializing in machinery for processing and manufacturing chocolate, candies, and other sweets, with a reputation for precision engineering and tailored, high-quality equipment solutions.

- Cooker Type

- Continuous

- Capacity

- 200 - 1200 kg/h

- Agitation Method

- Counter Stirrers

- Heating Method

- Steam Jackets

- Emulsification

- Yes

- Caramelization

- Simultaneous Cooking

- Residence Time

- Adjustable via Weir Design

- Working mechanism

- Continuous cooker with integrated caramelization

- Batch vs. continuous operation

- Inline Continuous

- Integrated steps

- Cooking and caramelization

- Agitation method

- Two counter stirrers

- Residence time control

- Special weir design

- Emulsification level

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank Shape

- Specially designed with multiple steam jackets

- Feed Method

- Solution pumped through the bottom

- Discharge Method

- Via special weir design

- Agitation Type

- Two counter stirrers for emulsification

- Control panel type

- Touchscreen

- Integration possibilities

- PLC integration

- Discharge method

- Weir design

- Compact footprint

- Yes