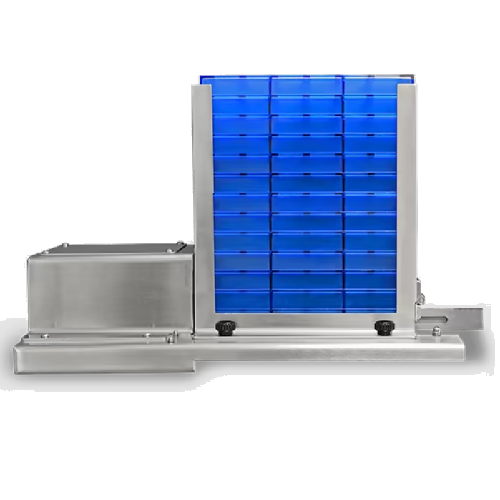

Automatic chocolate mould loader

Streamline your chocolate production with seamless mould loading, optimizing efficiency in creating ganache-filled chocolates, truffle shells, and more.

Loads Chocolate Moulds Efficiently and Precisely

The Tuttuno Mould Loader from Selmi Group is an essential component for chocolate manufacturers and confectionery producers aiming to enhance productivity. Specializing in precise and efficient mould loading, it integrates seamlessly into the chocolate production line, handling applications such as chocolate bars, ganache fillings, and truffle shells. Powered and interfaced via the Tuttuno Oneshot system, it requires a compressed air source for optimal performance, ensuring continuous and automatic operations. Capable of loading moulds measuring 275x175mm, it supports high throughput alongside Tuttuno’s dosing depositor machines, such as the One Shot Tuttuno 4 and 9. This equipment is tailored for industries focused on food and confectionery, offering chocolate manufacturers a reliable solution for load handling, with an emphasis on energy efficiency and streamlined production capabilities.

Benefits

- Enhances productivity by ensuring precise and rapid mould loading for continuous production.

- Minimizes labor involvement with fully automated operations, reducing operational costs.

- Integrates seamlessly into existing production lines, promoting smoother workflow and efficiency.

- Adapts to various product sizes with its flexible mould compatibility.

- Supports energy-efficient operation, optimizing compressed air usage for reduced energy expenses.

- Applications

- Cocoa products, Ganache fillings, Coffee, Sweets, Spreadable creams, Dried nuts, Chocolate, Truffles

- End products

- Nut pastes, Truffle shells, Chocolate bars, Ganache-filled chocolates, Chocolate enrobed sweets, Roasted coffee beans, Cocoa mass, Spreadable chocolate creams

- Steps before

- Chocolate Melting, Chocolate Mixing, Compressed Air Connection

- Steps after

- Mould Cooling, Demoulding, Chocolate Packaging

- Input ingredients

- chocolate, ganache fillings, compressed air

- Output ingredients

- chocolate moulds, filled chocolate products

- Market info

- Selmi is renowned for manufacturing high-quality chocolate processing equipment, such as tempering, enrobing, and cooling machines, with a strong reputation for precision, innovation, and reliability in the confectionery and chocolate industry.

- Automation

- Powered by Tuttuno Oneshot

- Air Supply Requirement

- Connection to a compressed air source

- Moulds Dimension

- 275x175 mm

- Hourly Production Rate (Tuttuno 4)

- About 120/125 moulds

- Hourly Production Rate (Tuttuno 9)

- Up to 360 moulds

- Working mechanism

- Automatic mould loading

- Integrated steps

- Simultaneous depositor and dispensing

- Automation level

- Powered and interfaced via Tuttuno Oneshot

- Batch vs. continuous operation

- Batch

- Compressed air requirement

- Connected to a compressed air source

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- 275x175 mm moulds

- Compatible machines

- One Shot Tuttuno 4, 9

- Mould dimensions

- 275x175 mm

- Connection requirement

- Compressed air source

- Integration compatibility

- Tuttuno Oneshot

- Footprint

- Compact

- Interfacing method

- Powered and interfaced via TUTTUNO ONESHOT

- Control panel type

- Integrated with TUTTUNO ONESHOT

- Integration possibilities

- Powered and interfaced via TUTTUNO ONESHOT

- Compressed air connection

- Required