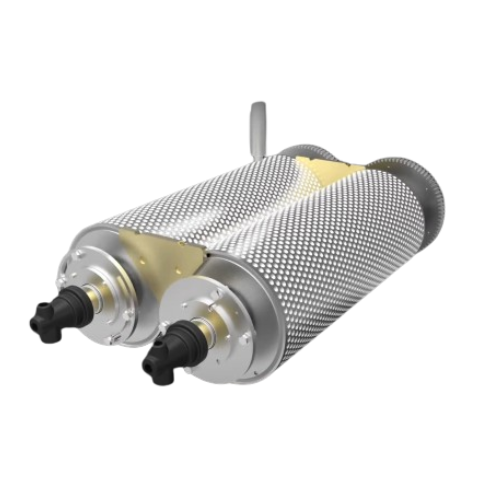

Chocolate moulding line for lentils, balls, and eggs

Achieve precision and efficiency in molding chocolate centers for lentils, balls, and eggs with advanced rollers and integrated cooling technology, ensuring consistent shape and quality for downstream sugar-coating and polishing.

Moulds and Cools Chocolate Products Precisely

The Eriksen Moulding Line from Aasted is engineered for chocolate and confectionery industries, optimizing the production of chocolate eggs, lentils, and balls. This line features cooled precision rollers that mould chocolates into uniform shapes, cooled between -15° and -25°C, ensuring a perfect gloss and consistency. The Type ES offers a mobile roller section, a cooling unit, and a sieve drum to streamline production, while Type E provides a stationary roller setup. Both models support future expansion with additional rollers and conveyors. Suitable for high-speed continuous operations, this line integrates easily into existing setups, allowing quick changeovers and minimal downtime. It’s particularly efficient in energy use due to optimized cooling elements and supports easy maintenance through modular design.

Benefits

- Ensures consistently high-quality chocolate products with precision cooling and moulding.

- Enhances productivity with quick and simple product changeovers.

- Minimizes downtime through easy maintenance and modular component design.

- Integrates seamlessly into existing production lines for scalable operations.

- Improves operational efficiency with energy-optimized cooling systems.

- Applications

- Chocolate, Sweets, Bakery, Confectionery

- End products

- Chocolate eggs, Chocolate lentils, Chocolate balls

- Steps before

- Melting, Mixing, Refining, Conching

- Steps after

- Sugar-coating, Polishing, Packing

- Input ingredients

- chocolate, white chocolate, milk chocolate, dark chocolate

- Output ingredients

- chocolate centers, small lentils, chocolate balls, chocolate eggs, sugar-coated chocolates

- Market info

- Aasted is known for its expertise in manufacturing equipment for the chocolate, bakery, and confectionery industries, offering solutions like tempering, molding, and baking machinery with a strong reputation for innovation and quality.

- Product Type

- Chocolate centers - lentils, balls, eggs

- Precision Temperature Range

- -15° to -25°C

- Automation

- Roller changeover

- Cooling System

- Cooled precision rollers, Cooling unit, tunnel

- Sugar-Coating Compatibility

- Yes

- Changeover Efficiency

- Easy exchange of rollers

- Production Capacity

- High speed and capacity

- Material Type

- White, milk, dark chocolate

- Product Output

- Uniform and accurate shapes

- Working Mechanism

- Cooled precision rollers

- Integrated Steps

- Sugar-coating or polishing

- Cooling Temperature

- -15°C to -25°C

- Batch vs. Continuous Operation

- Batch

- Changeover Time

- Easily performed between products

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Stainless steel

- Abrasion resistance

- High

- Density/particle size

- 0.5–2 g/cm³

- Roller type

- Mobile / Stationary

- Cooling unit

- Included

- Cooling tunnel

- Included

- Roller section

- Extra rollers available

- Discharge method

- Sieve drum

- Conveyor option

- Available

- Roller Type

- Mobile / Stationary

- Cooling Unit

- Included

- Conveyor Integration

- Available

- Sieve Drum

- Included

- Additional Rollers

- Available

- Changeover Efficiency

- High efficiency with extra roller sets