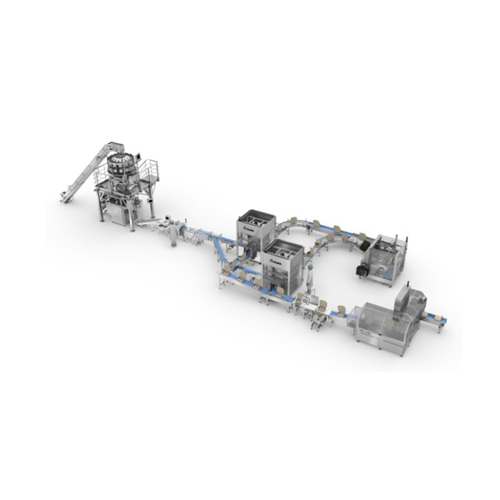

Automated bagging system for confectionery products

Achieve seamless integration in your confectionery packaging line with this high-speed, fully automated solution that streamlines bagging, packing, and weighing processes.

Automates Bagging and Packing of Confectionery

The fully automated solution from ULMA Packaging integrates vertical baggers, case erectors, case packing cells, and box closers to optimize the bagging and packing process for confectionery products. This solution is designed to support a variety of applications, including gummy bears, chocolate bars, and biscuits, ensuring high-speed operation with continuous workflow. Utilizing a sophisticated weighing and packaging mechanism, it efficiently manages diverse product sizes and shapes. With multi-format capabilities, it allows automatic configuration changes for varying product specifications, enhancing production line flexibility.

Engineered for seamless integration, the system offers full automation with PLC controls, enabling remote monitoring and operational adjustments. Its robust design minimizes energy use with optimized motor control, while maintaining high throughput rates to meet the demands of large-scale confectionery production. The equipment is constructed from food-grade materials to ensure safety and hygiene, with easy-to-clean features for reduced maintenance downtime. Additionally, ULMA provides comprehensive engineering support with options for customization to meet specific production requirements.

Benefits

- Increases production efficiency with high-speed, continuous operation.

- Enhances flexibility with automatic multi-format changeovers.

- Reduces labor costs by streamlining packaging processes through full automation.

- Minimizes energy consumption with optimized motor control systems.

- Ensures product safety with food-grade materials and hygienic design.

- Applications

- Sweets, Confectionery, Bakery, Biscuits

- End products

- Ginger cookies, Gummy bears, Digestive biscuits, Macaroons, Hard candies, Muffins, Shortbread biscuits, Jelly beans, Chocolate bars, Caramel chews, Croissants, Éclairs, Lollipops, Wafer cookies

- Steps before

- Weighing, Multihead weighing

- Steps after

- Case packing, Box closing, Case packing cells, Box Closer

- Input ingredients

- confectionery, sweets, multihead weigher product, empty boxes

- Output ingredients

- bagged confectionery products, packaged sweets, filled boxes

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation

- Fully automated

- Bagging method

- Vertical bagging

- Packaging type

- Bagging and case packing

- Robot type

- Delta robot

- System configuration

- Multi-format

- Flexibility

- Configurable format changes

- Grouping system

- Bag grouping system

- Handling method

- Vacuum system

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous operation

- Format change configurability

- Automatic

- Robotic system

- Delta robot with vacuum system

- Case packing flexibility

- Multi-format

- Heat sensitivity

- High/Medium/Low

- Container shape

- Rectangular/Cylindrical

- Packaging type

- Bag/Box

- Vertical bagger

- Vertical packaging machine

- Case erector

- Multi-format and automatic

- Case packing cells

- Contains a delta robot and bag grouping system

- Box closer

- Multi-format and automatic

- Discharge method

- Automatic case packing

- Format Change

- Multiple Formats Configurable and Automatic

- Multihead Weigher Integration

- Available

- Delta Robot Selection

- Vacuum System for Manipulation

- Casing Tile Configurability

- Adaptable to Customer References

- Automatic Case Erector

- Multi-format and Automatic

- Automatic Box Closer

- Multi-format and Automatic