Making Chocolate Bars

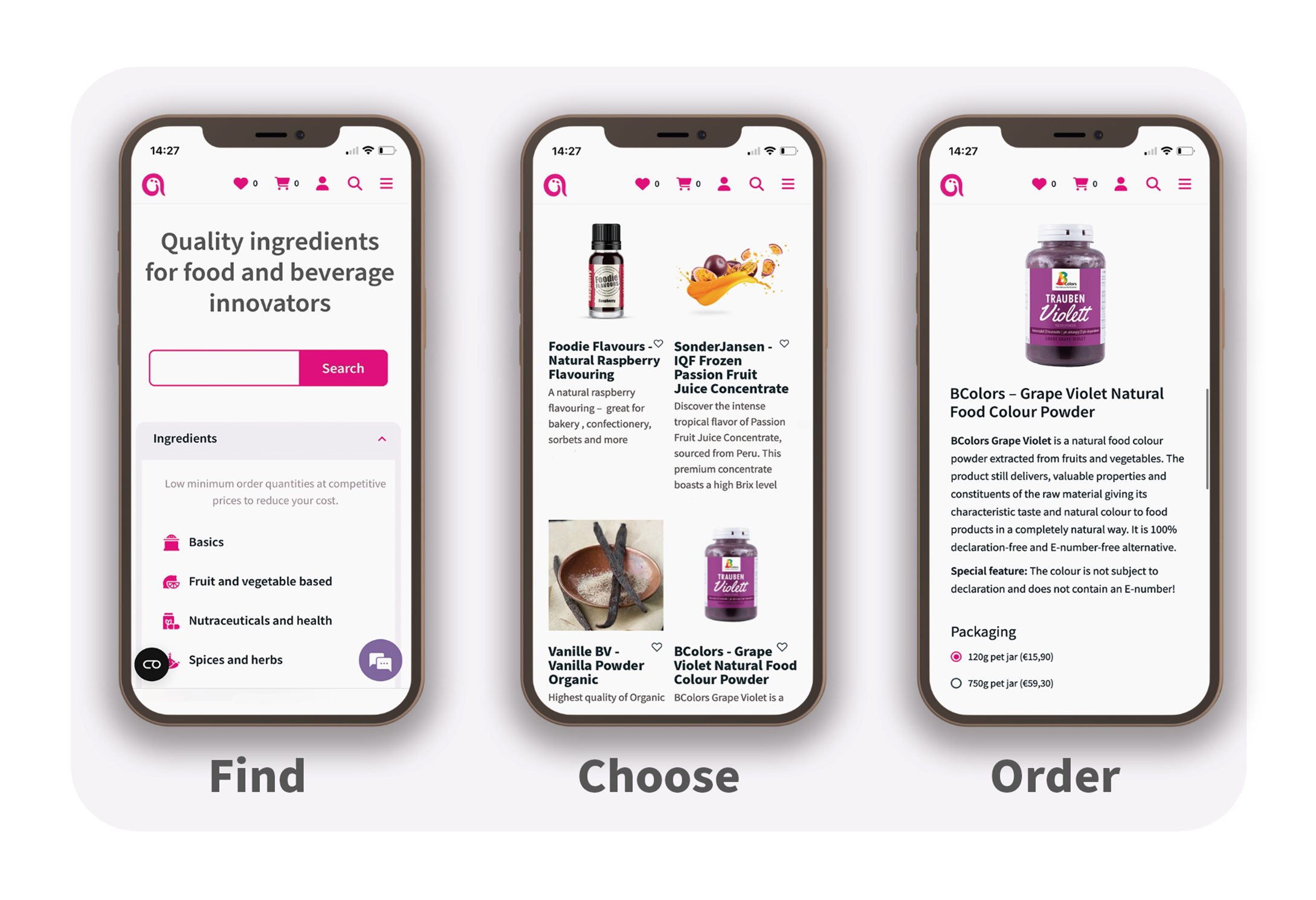

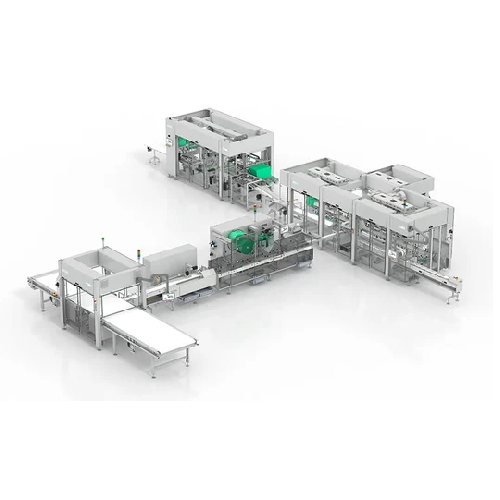

Find innovative production technology for making chocolate bars and connect directly with world-leading specialists

Chocolate bars are popular snacks and gifts for many occasions and events, dating back to the Mayans and the Aztecs. They may also include other ingredients such as caramel, fruits, or nuts. Considering making chocolate bars? Make sure, though, that your chocolate bar making equipment can cover various processes such as grinding and melting, tempering, refining, and cooling.

Technology picks for chocolate bars

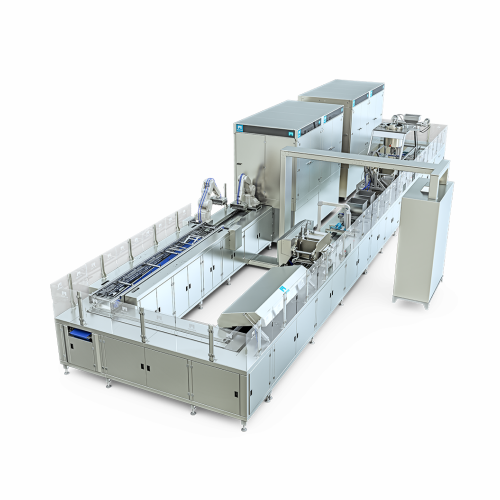

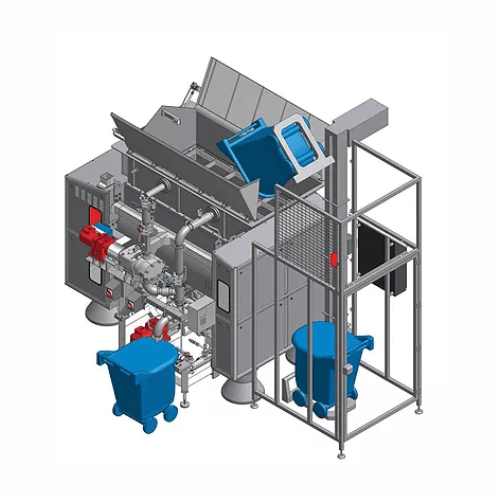

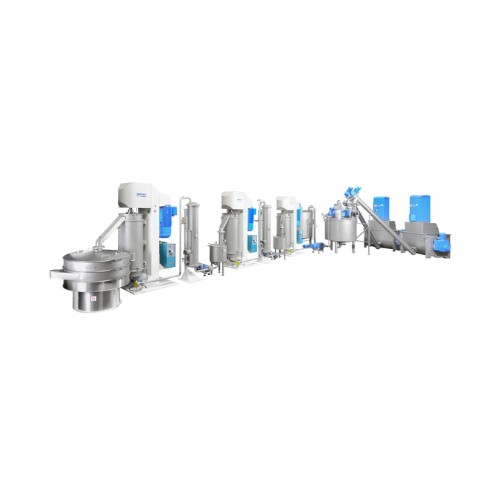

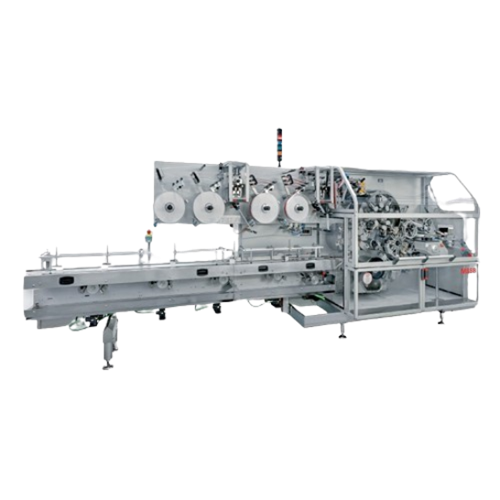

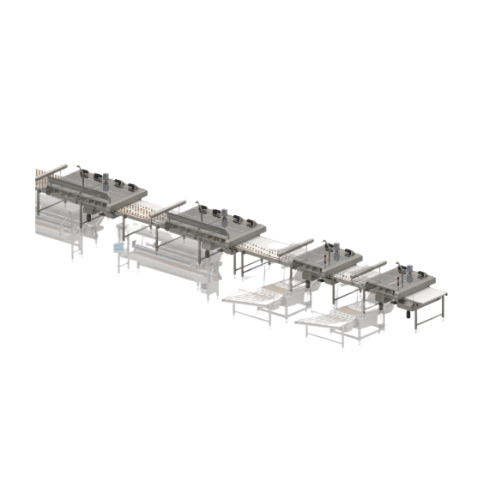

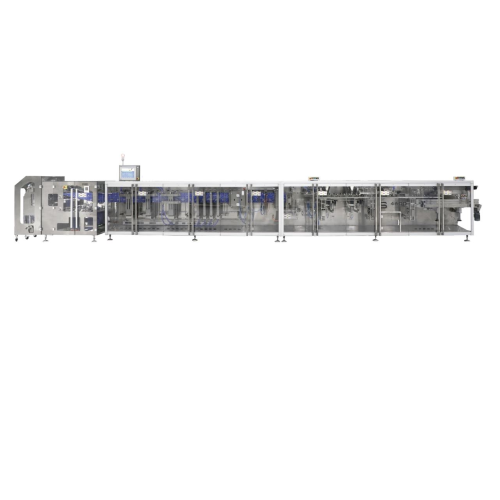

Artisan line for fine chocolate mass production

Transform raw cocoa beans into exquisite chocolate through precise control...

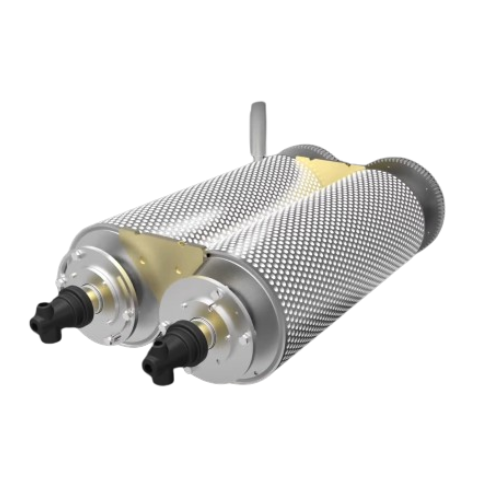

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...

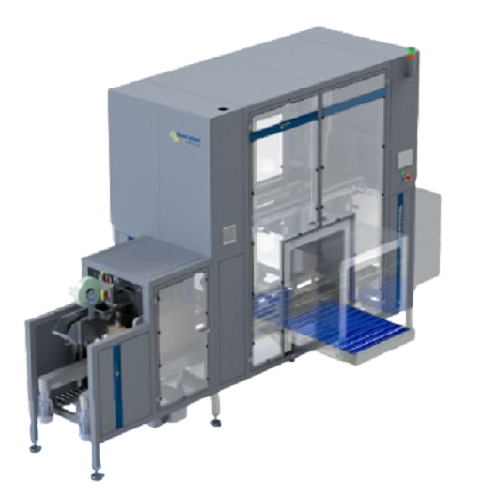

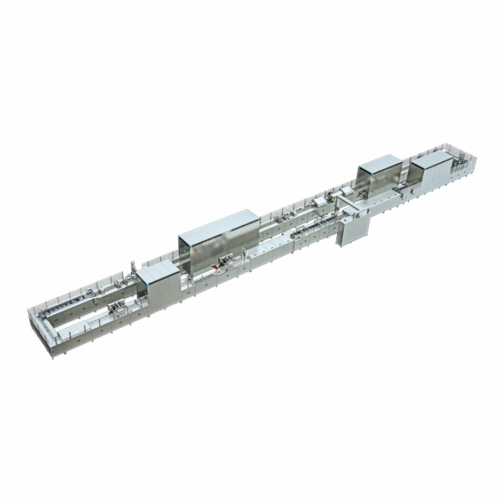

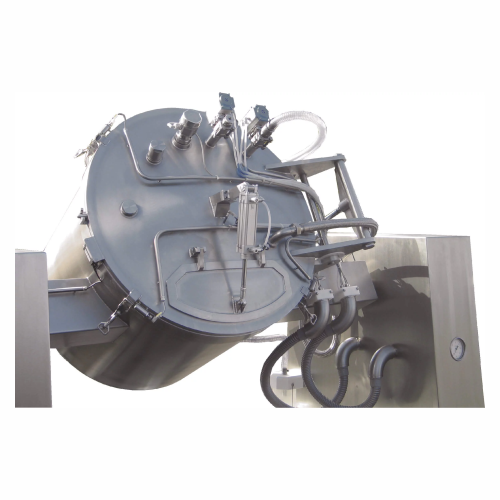

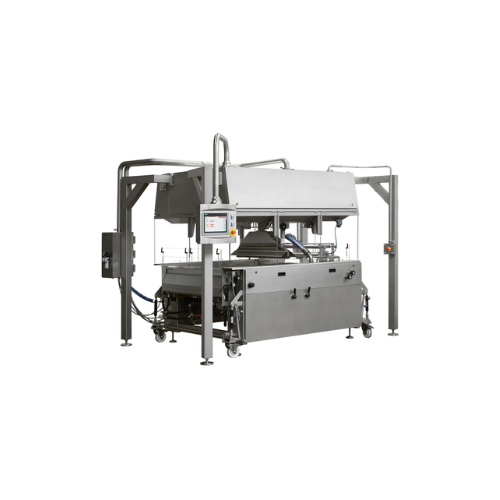

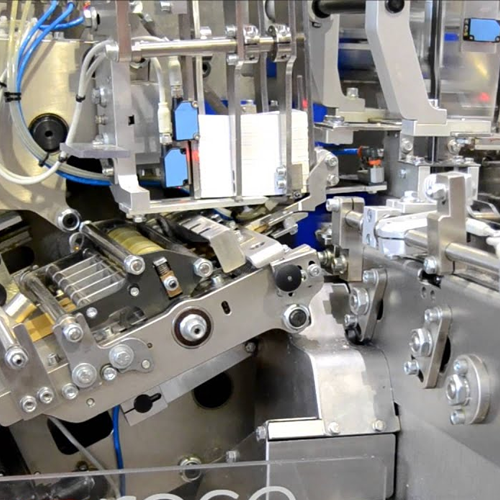

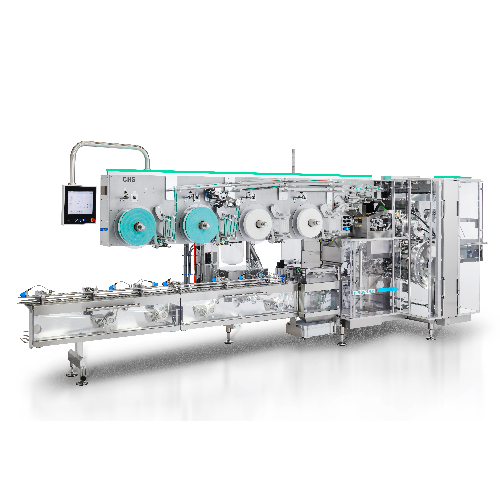

Chocolate enrober for bars, cookies, and wafers

Ensure consistent and high-quality enrobing for confections with advanced ...

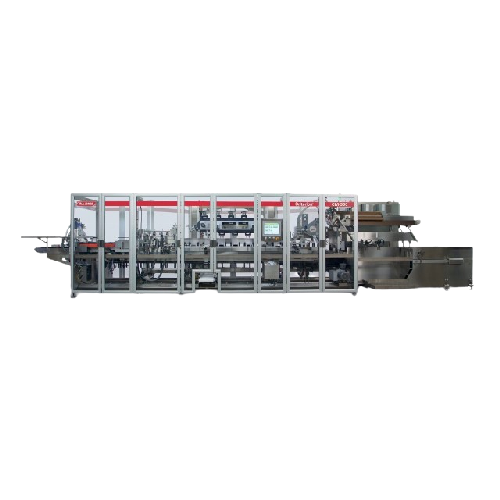

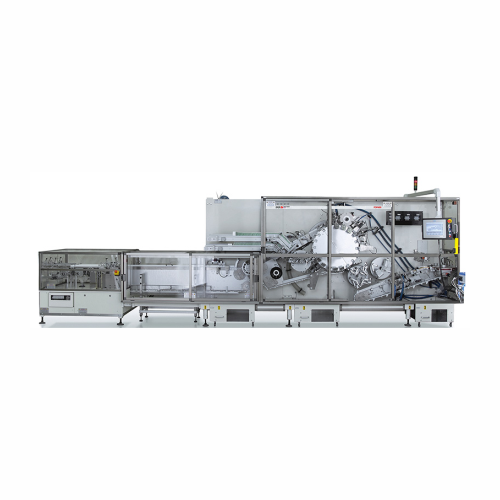

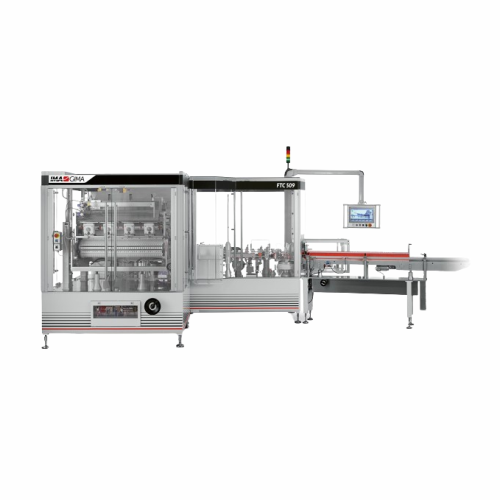

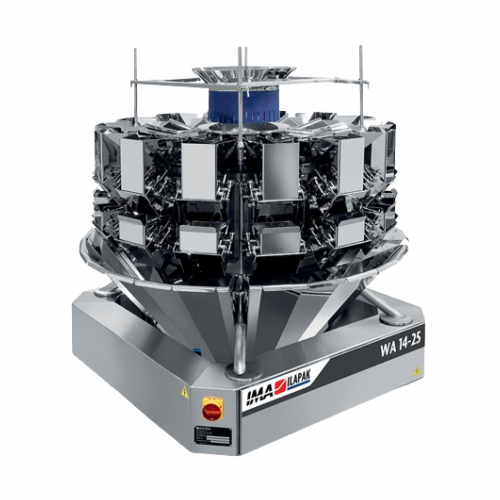

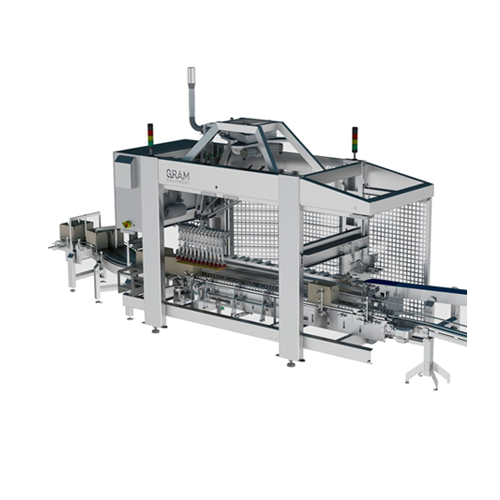

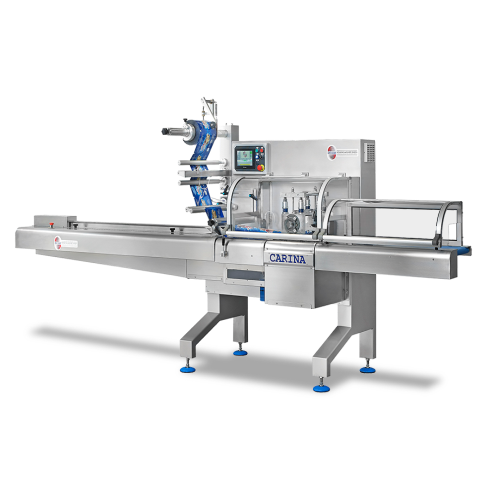

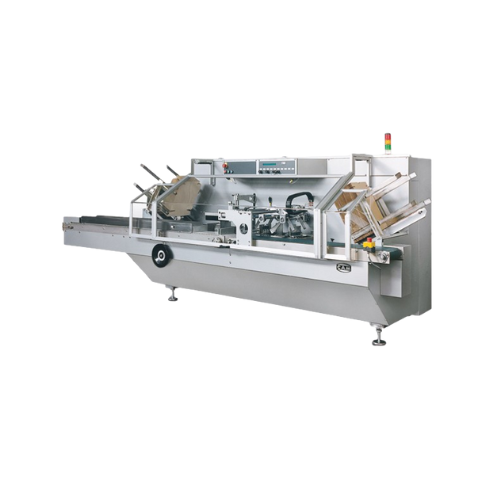

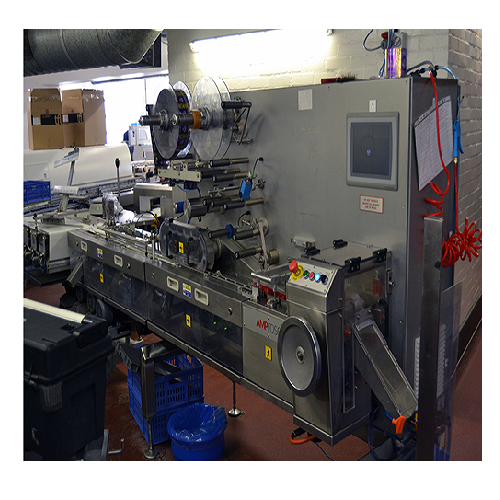

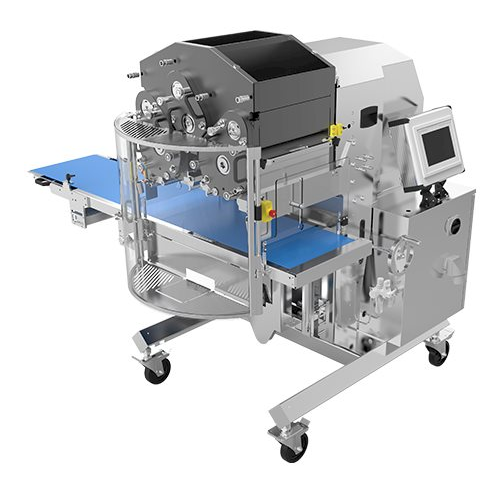

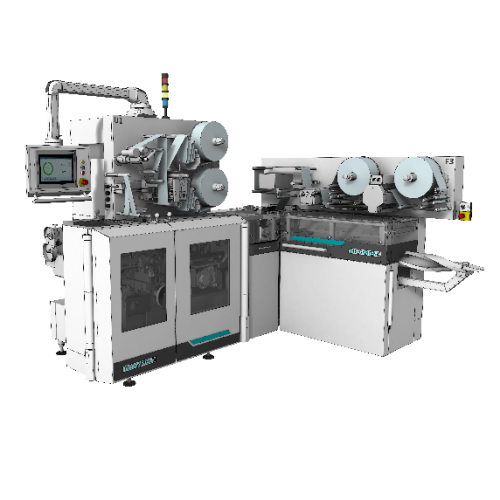

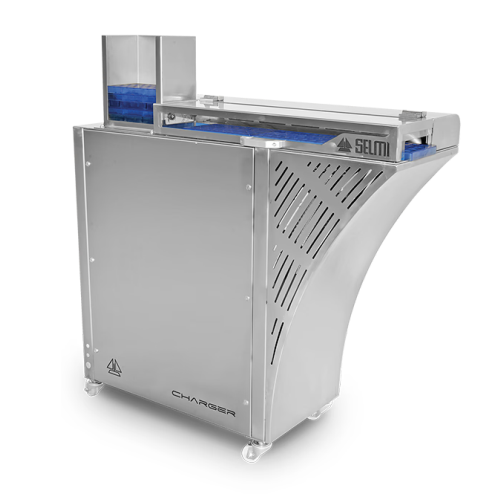

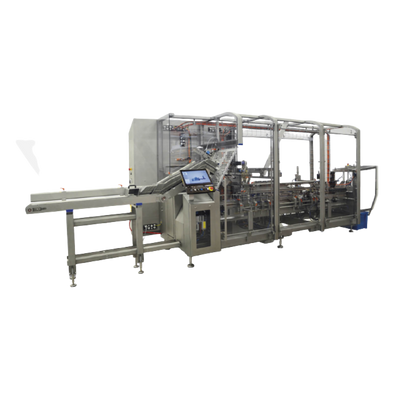

High-speed wrapping system for chocolate bars

Ensure quick and precise packaging for chocolate bars with a high-speed syst...

Stories about chocolate bars

Tell us about your production challenge

Which chocolate bar making equipment can help you in making chocolate bars?

Chocolate bars are bar-shaped confections made of solid chocolate. The whole bean to bar chocolate making equipment focuses on two main processes: roasting and winnowing of cacao nibs and chocolate tempering. If you are sourcing tempered chocolate, your process will focus on melting your raw materials, refining, and cooling.

Tempering the chocolate allows the formation of Type V crystals, while refining the chocolate reduces the particle size of cocoa solids and crystals to 10 to 30 microns. Once the desired texture and flavor profile is achieved, a filling machine transfers your slurry to clean and dry molds.

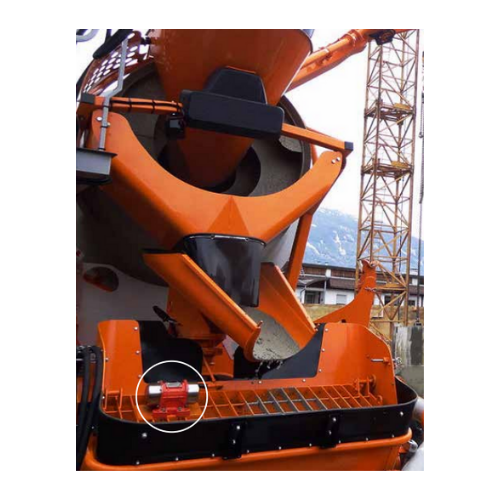

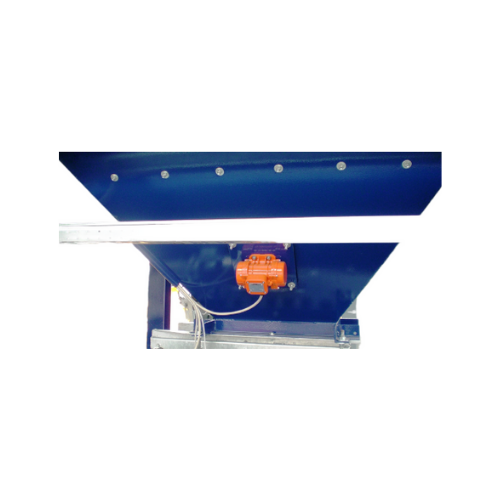

A conveyor belt vibrates and shakes the mold to ensure proper settling of chocolate and removal of all air bubbles. Then chocolate is sent to a refrigeration room and allowed to cool. After cooling and solidifying, chocolate bars are removed from the molds, and you can then pack and wrap them in foil or paper packaging following the appropriate labeling standards.

Can you create chocolate bars without tempering the chocolate?

Definitely. That’s because some chocolate bars are made with compound chocolate. Compared to pure chocolate, compound chocolate comprises approximately 35-40% hard fat, 8-18% cocoa, about 2% milk solids, lecithin, and flavor. Isn’t anything missing? That’s right, cocoa butter.

Vegetable fats such as coconut oil and palm oil are used to replace cocoa butter in compound chocolate. Since there is no cocoa butter, you don’t have to temper your chocolate but simply melt it at approximately 35°C to 37°C. In this case, chocolate bars are not made by molding, but compound chocolate is used to replace enrobed chocolate on a product.

Pink is not just a color and ruby chocolate bars are proof of that

Last 2017, Barry Callebaut introduced the fourth variant of chocolate along with milk, dark and white varieties: the ruby chocolate. Compared to the chocolate we know, this type had a pink color and a slightly sweet and sour flavor. Ruby chocolate is made from the ruby cocoa beans by minimizing fermentation (no more than three days or less), treating them with an acid, and removing fatty acids to retain the color.

If you are planning to produce ruby chocolate bars, you can still use the same chocolate bar processing method. To make your ruby chocolate bars, you will also need to grind and melt the beans or bars, subject these to tempering and refinement, and finally to cooling, cutting, and packaging. Other than the ruby cacao beans, there is no difference in their production method or chocolate bar making equipment compared to pure chocolates, so get that pink on if you can!

Healthy chocolate bars: a dream or reality?

Chocolate bars and chocolate are not really considered a healthy food in general. However, studies have shown that there are compounds in chocolate that are helpful in maintaining overall body health.

The main ingredient, cocoa, contains flavonoids, such as catechin, epicatechin, and procyanidins, which help lower cholesterol, reduce inflammation, and improve blood flow. In addition, there have been studies proving it can be beneficial for your brain by enhancing the blood flow needed for memory and thinking.

Focusing on cocoa, you can efficiently market high-cocoa, high purity dark chocolates for these health effects. Higher cocoa content translates to a higher amount of these flavonoids, thereby increasing the health value of your chocolate bars. Some chocolate brands also add extra flavonoids for additional nutritional value. Furthermore, you may consider adding fresh ingredients, such as fruits, vegetables, or nuts. Healthy artificial sweeteners, such as stevia and coconut sugar, may also be considered to improve sweetness while reducing calories.

Processing steps involved in chocolate bars making

Which chocolate bars technology do you need?

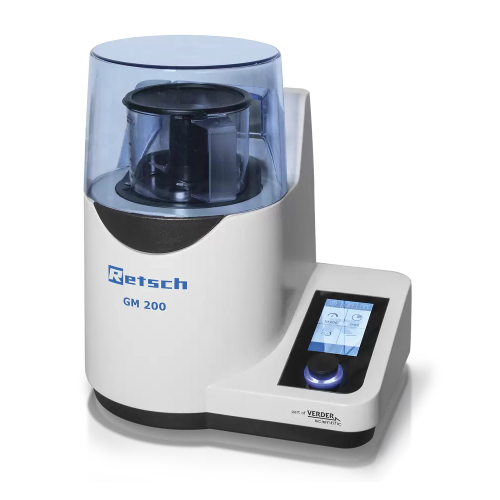

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

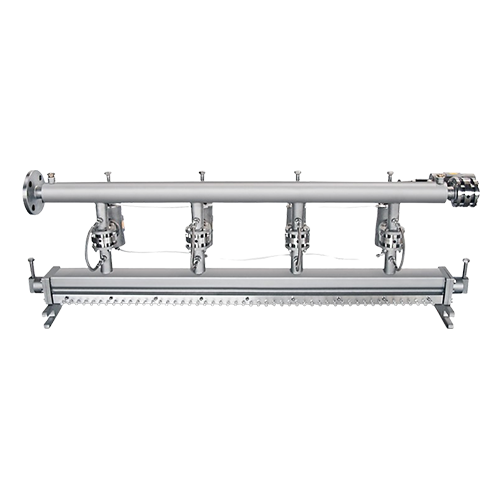

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

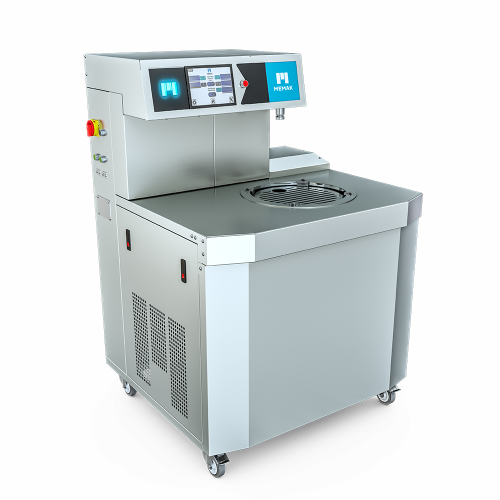

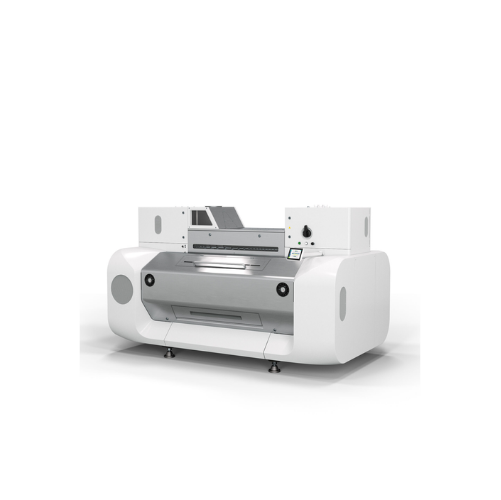

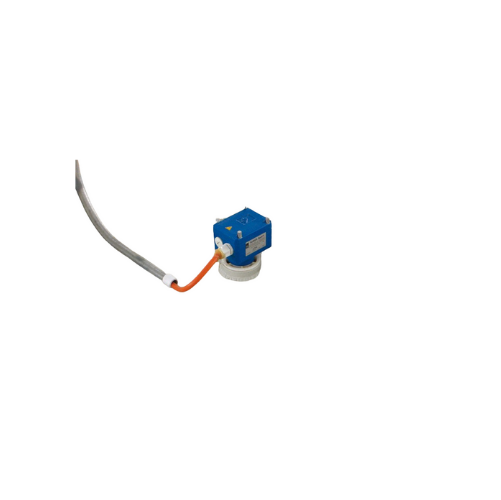

Chocolate tempering quality analyzer

Ensure your chocolate’s tempering precision with a device that accurately assess...

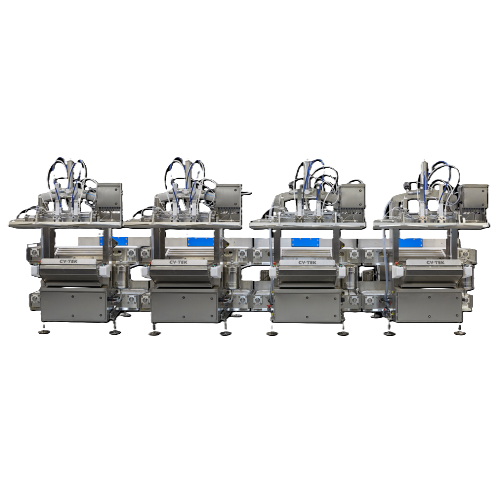

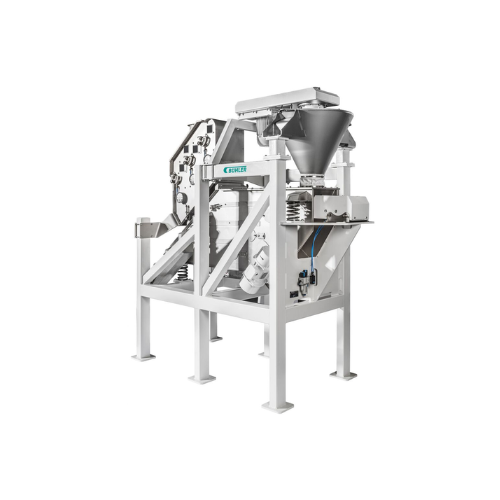

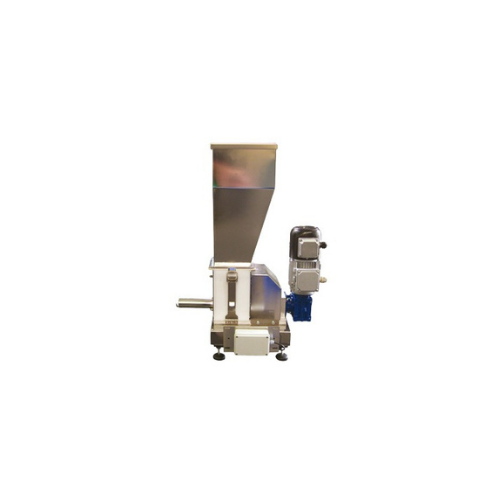

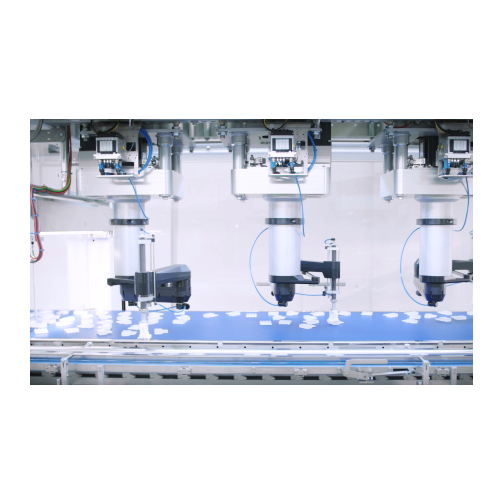

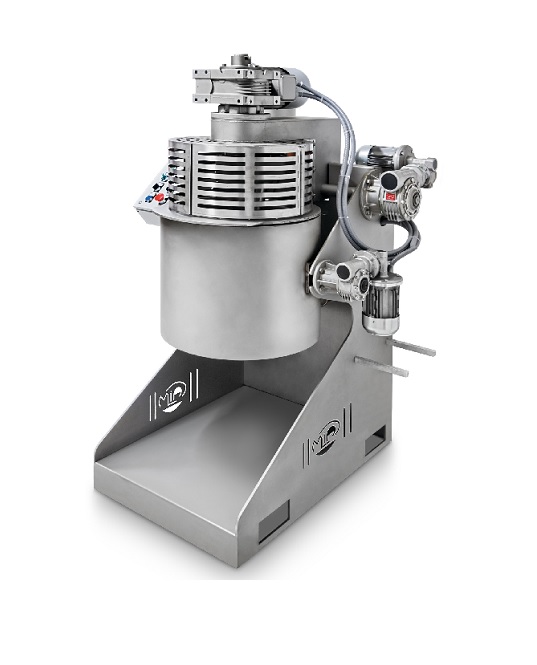

Precise dosing technology for praline and chocolate production

Streamline the production of pralines, chocolate bars, an...

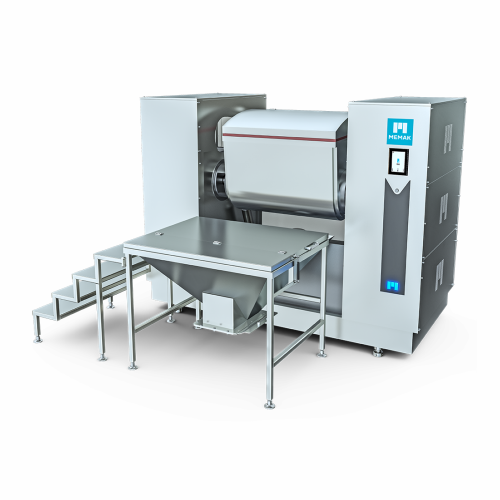

Chocolate block flaking solution

Enhance your confectionery production with versatile flaking capabilities, perfect for crea...

Heating cabinets for chocolate processing

Optimize your confectionery production by maintaining precise temperature contro...

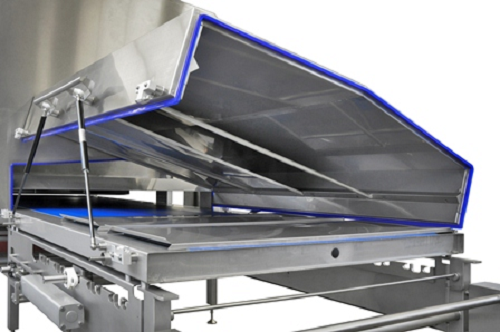

Chocolate melting trays for small-scale applications

Efficiently melt chocolate with precision and ease using compact, el...

Chocolate moulding system for small-scale production

Optimize your chocolate production by efficiently melting, tempering...

Pneumatic scrapers for chocolate mould filling

Achieve precise chocolate moulding with pneumatic scrapers that streamline ...

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

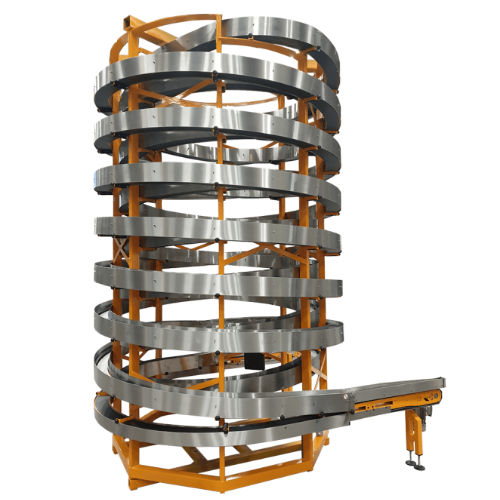

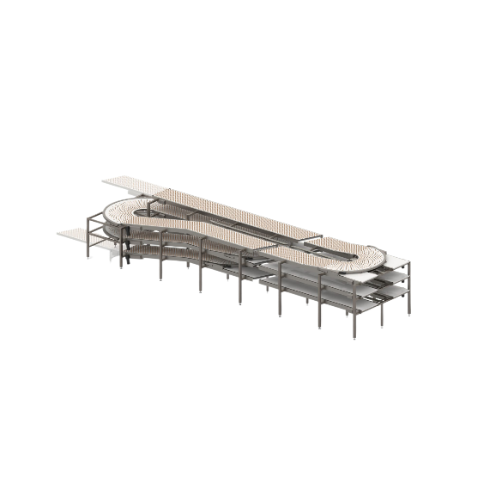

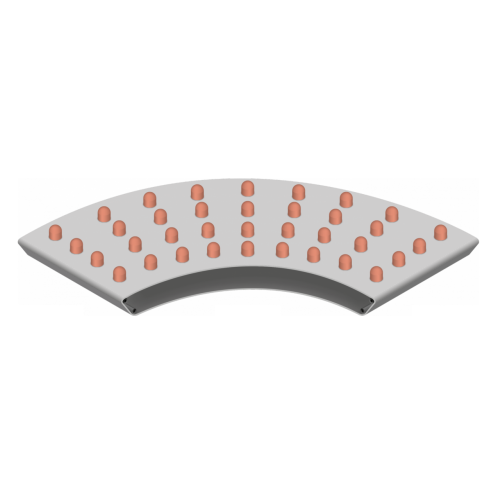

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

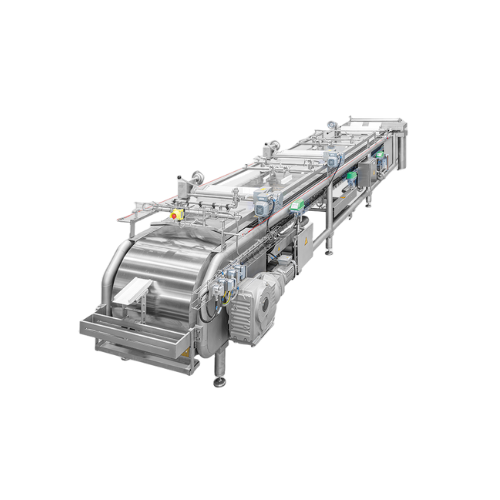

Cooling tunnel for biscuits and chocolates

Ensure product quality and consistency with precision-controlled cooling tunnel...

Chocolate decoration system for pralines and biscuits

Achieve intricate chocolate patterns and uniform coatings on confec...

Industrial chocolate flaking solution

Optimize your confectionery production with high-speed flaking technology, ensuring p...

Melting and mixing kettles for chocolate production

Achieve consistent melting and mixing of chocolates, butter, and jams...

Rapid chocolate and fat melting system

Optimize your confectionery production with an efficient solution designed to rapidl...

Continuous tempering machine for chocolate production

Streamline your chocolate production with precise tempering, ensuri...

Chocolate transport system for feeding and packaging

Enhance your chocolate production with a versatile transport system ...

Industrial chocolate flakes production equipment for decorative applications

Achieve perfect decorative chocolate curl...

Cooling tunnel for biscuit and chocolate production

Ensure consistent quality control in your confectionery production wi...

Continuous cooler for biscuits and chocolates

Enhance cooling efficiency for your confectionery and bakery production with...

Chocolate melter for large quantities

Efficiently melt and maintain the temperature of substantial chocolate quantities wit...

Melting and mixing kettle for chocolate production

Optimize your confectionery production with this versatile melting and...

Compact chocolate tempering solution

Enhance your chocolate products’ finish and efficiency: this compact solution en...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

Precision chocolate production from cocoa nibs

Achieve ultra-fine chocolate textures by utilizing stone conching to bring ...

Cooling tunnel for industrial pre-cooling

Efficiently reduce product temperatures with this custom-designed air cooling tu...

Batch tempering solution for chocolate production

Achieve precise temperature control for chocolate consistency and quali...

Cooling tunnel for artisanal biscuits and chocolates

Streamline your confectionery production with a cooling solution des...

Chocolate melting and mixing kettle for small-scale production

Streamline your confectionery production with a compact k...

Industrial chocolate flaking system

Achieve precise chocolate flake dimensions effortlessly, enhancing product textures and...

Double heating cabinet for melting and preheating chocolate

Optimize space while ensuring precise temperature control fo...

Compact chocolate flake maker

Effortlessly transform solid chocolate blocks into precise flakes and curls, enhancing the vis...

Electric melting tray for small-scale chocolate applications

Effortlessly melt and prepare chocolate with precision and ...

Dosing system for kügel chocolate moulds

Automate your chocolate production with precision dosing, seamlessly integrating m...

Chocolate filling application system for manons

Efficiently apply a variety of fillings, from delicate buttercream to rich...

Mini praline dosing system

Achieve precise dosing and versatile moulding for mini pralines and chocolate creations, streamli...

Dosing system for chocolate tablets

Enhance your confectionery production with a versatile solution for precise dosing and ...

Filling system for chocolates and pralines

Efficiently dose, mold, and fill chocolates to create a variety of enticing con...

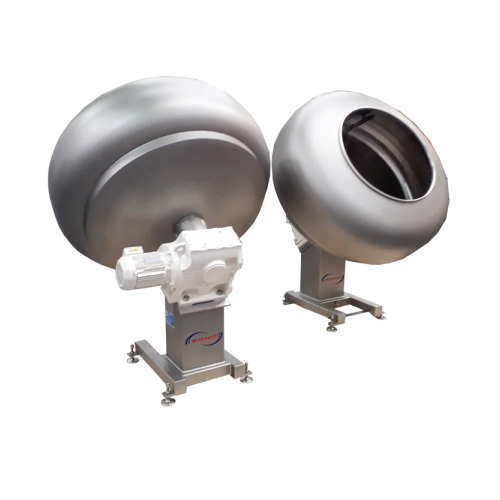

Chocolate coating system for nuts and small biscuits

Effortlessly achieve consistent chocolate coatings on nuts, fruits, ...

Compact chocolate moulding system

Optimize your chocolate creations with a compact system designed for easy melting, temper...

Compact chocolate moulding solution 3-in-1

Streamline your confectionery creations with a versatile 3-in-1 machine that se...

Linear belt vibratory weigh filler for solid chocolate

Optimize your chocolate production by minimizing product giveaway ...

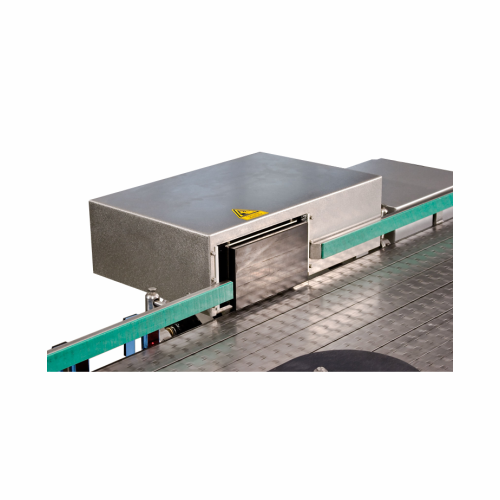

Automated bag sealing for packaging lines

Enhance your packaging efficiency by seamlessly integrating an automated bag sea...

Belt loaders for automated food packaging

Streamline your packaging line with precision-engineered belt loaders, designed ...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Top load cartoning system for pharmaceuticals

Optimize your packaging line with precision top-load cartoning, designed for...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Fat slurry homogenization mill for chocolate processing

Achieve precise chocolate and confectionery homogenization with e...

Industrial storage tank for chocolate ingredients

Ensure consistent quality for your confectionery products by integratin...

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line tha...

Chocolate moulding line for center-filled chocolates

Streamline your chocolate production with a versatile moulding line ...

Chocolate one-shot moulding line

Streamline your chocolate production with a high-speed moulding line designed to simultaneo...

Automatic chocolate feeding conveyor

Efficiently connect your chocolate production to wrapping stages with this high-speed ...

Chocolate wrapping machine for confectionery production

Achieve precision and elegance in packaging with high-speed wrapp...

Chocolate raw material pre-mixer

Streamline your chocolate production by efficiently combining raw ingredients in a single p...

Chocolate storage tank

Optimize your chocolate production with seamless storage solutions that ensure consistent quality and ...

Chocolate tempering solution for industrial production

Achieve consistent chocolate crystallization with a machine that e...

Conching solution for chocolate processing

Achieve optimal chocolate texture and flavor by ensuring efficient conching, cr...

Continuous chocolate mill

Enhance the texture and quality of your chocolate products with this high-speed milling solution, ...

Industrial fat melting tank for bakery and chocolate production

Efficiently melt solid fats to precise temperatures with...

Laboratory type ball mill for chocolate and bakery applications

Optimize your R&D processes with precise grinding a...

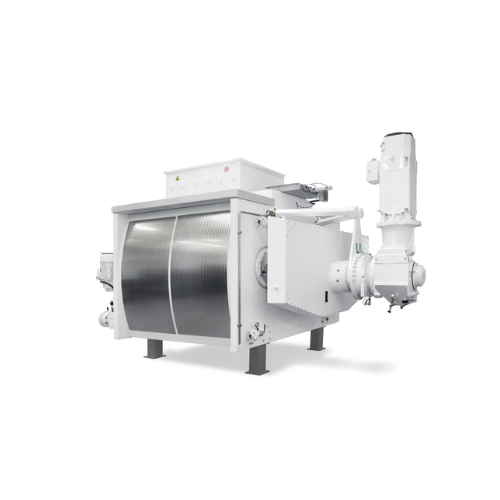

High viscosity material mixer for bakery and chocolate

Efficiently mix and knead high-viscosity materials for premium cho...

Automatic chocolate shell moulding line

Enhance your production capabilities with a cutting-edge moulding line that deliver...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Chocolate moulding press for coco mass

Enhance your production line with precise chocolate moulding capabilities, shaping e...

Chocolate cooling tunnel

Enhance your confectionery production with efficient cooling and precise crystallization, critical f...

Enrobing system for high-quality chocolate applications

Enhance your confectionery line with precise chocolate coating ca...

Chocolate ball mill for processing chocolate mass

Enhance your confectionery production with precision mixing and uniform...

Advanced convection oven for bakery applications

Enhance your bakery’s production efficiency and product quality with a ve...

Industrial chocolate and dough sheeter

Streamline your chocolate and pastry production with robust dough sheeting and rolli...

Dough aligning system for bakery production

Enhance your bakery’s precision and efficiency with a system that ensure...

Combinex for baking high-quality breads and pastries

Optimize your bakery or confectionery production with precise temper...

Laboratory refiner/conche for chocolate processing

For chocolate producers seeking precise control over texture and flavo...

Duplex refiner/conche for chocolate production

Effortlessly transform cocoa, sugar, and other ingredients into smooth, fin...

Commercial chocolate refiner/conche

Elevate your chocolate production with a versatile 5-in-1 solution, integrating cocoa m...

Chocolate refiner/conche system

Streamline your chocolate production with a versatile solution that combines grinding, mixin...

Industrial product rework system

Efficiently rework products while minimizing waste with a robust system designed for precis...

Cocoa butter and cocoa liquor melting unit

Optimize your chocolate production with a unit designed for efficient melting a...

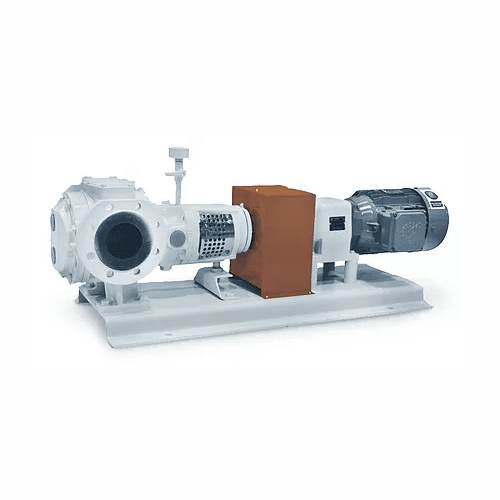

Chocolate pump for confectionery production

Effortlessly pump and convey a range of chocolate-based products with precisio...

Chocolate storage tank for large-scale manufacturing

Enhance your chocolate production line with a storage system designe...

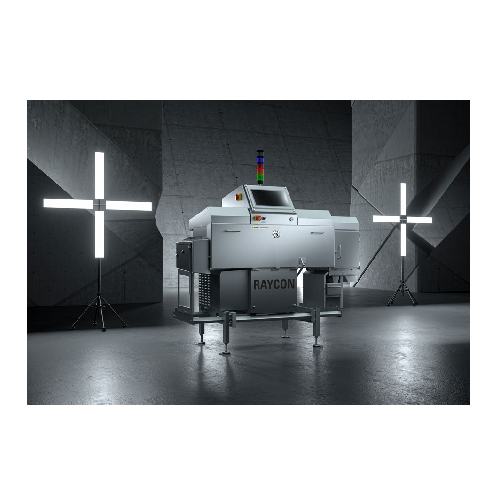

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

Metal detector for conveyorized applications

Enhance your production line by ensuring product safety with advanced metal d...

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Conveyorized food metal detector for high-care environments

Ensure food safety with advanced metal detection tailored fo...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

Compact x-ray inspection system for food safety

Enhance food product safety with advanced x-ray inspection, targeting both...

Top-loading cartoner for bar and confectionery packaging

Optimize your high-speed packaging operations with a flexible ca...

Fold wrapping solution for chewing gum tabs

Streamline your high-speed packaging line with a solution that expertly wraps ...

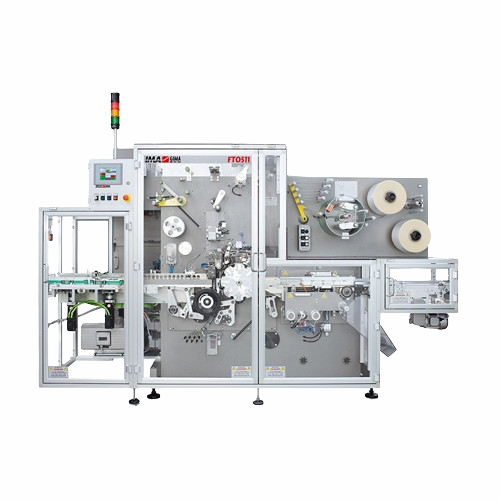

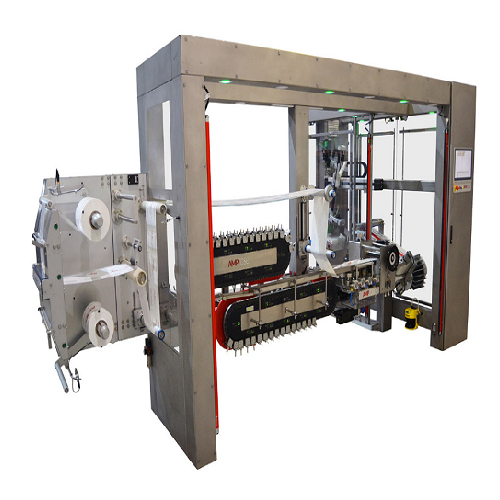

Twin station fold wrapping machine for chocolate bars

Efficiently transform diverse chocolate and confectionery items int...

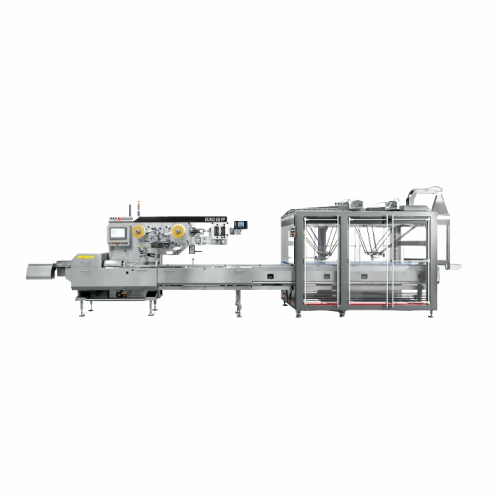

Horizontal flow wrap solution for chocolate bars

Achieve high-speed precision in packaging with a machine designed to hand...

Metal detector checkweigher combination system for food products

Simultaneously detect metal contaminants while ensuring...

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Fold wrapping solution for round pharma tablets

Ensure precise and gentle packaging of round tablets with our innovative f...

Cryogenic chilling system for meat processing

Ensure uniform temperature control in meat production lines to maintain prod...

Entry-level moulding machine for small to medium production

Ideal for scaling new product lines, this versatile moulding...

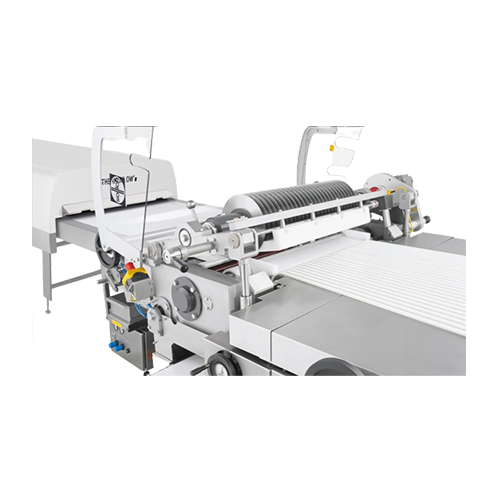

High speed rolling line for confectionery production

Enhance your confectionery production with a versatile rolling line ...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

Tote bin dumper for bulk product transfer

Streamline your bulk product handling with a solution that efficiently transfers...

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Optical sorter for food processing

Enhance your production line with advanced sorting technology that meticulously inspects...

Distribution conveyor systems for food processing

Streamline your food processing pipeline with precision-engineered dist...

Feed conveyors for efficient product presentation

Optimize your production line with feed conveyors designed to streamlin...

Industrial food grading system for vegetables

Optimize your production line with a versatile food grading system, ensuring...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

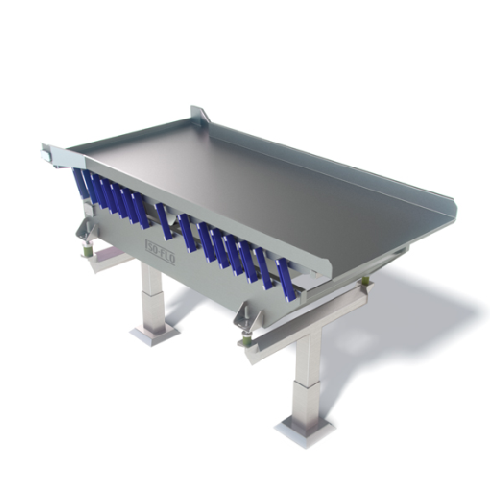

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

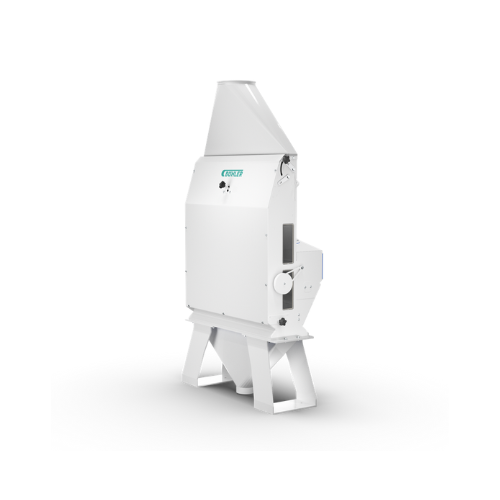

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

Sanitary pigging system for viscous food products

Efficiently recover high-value viscous products like chocolates and cre...

Horizontal cartoning solution for pharmaceutical packaging

Streamline your confectionery packaging with high-speed, cont...

Compact cartoner for pharma packaging needs

Achieve seamless integration in your production line with a cartoning solution...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Entry-level flow wrapping machine for small and medium products

Optimize your packaging line with a high-speed flow wrap...

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

High-speed overwrapping for display boxes

Achieve seamless overwrapping of display boxes with ultra-high-speed capabilitie...

Feeding system for single wrapping lines

Optimize your high-speed wrapping operations by ensuring precise product alignment...

Flow wrapper for high-speed confectionery packaging

Achieve gentle, high-speed packaging for delicate confectionery items...

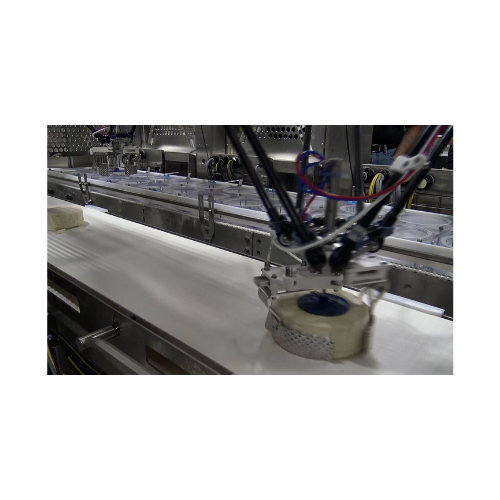

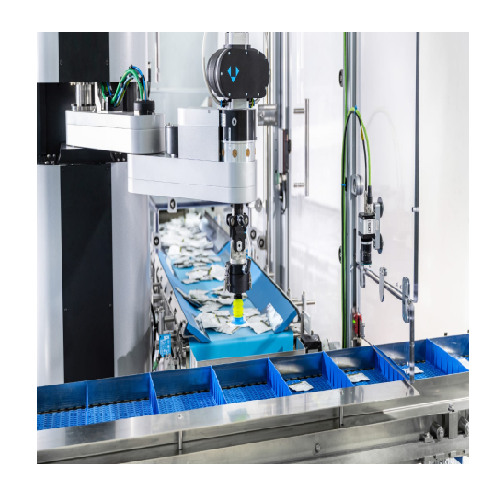

Flow wrapping with pick and place robots

Streamline your confectionery and bakery packaging with precision flow wrapping, u...

Flow wrapping system for hygienic food packaging

Enhance your packaging line with a modular flow wrapping solution that en...

Over wrapping solution for foodstuffs and beverages

Optimizing film over wrapping for challenging thin materials, this co...

Vertical cartoning system for confectionery products

When you need high-speed, versatile cartoning capabilities for varie...

Overwrapping solution for medium size display boxes

Streamline your packaging line with high-speed, continuous overwrappi...

Monoblock loading unit for confectionery packaging

Optimize your confectionery production line with a compact unit that i...

Wrap-around case packer for coated sweets

Effortlessly enhance product presentation and shelf-readiness by securely packin...

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

Intermittent motion cartoner for confectionery packaging

For manufacturers needing versatile packaging solutions, this ca...

Vertical baggers for confectionery packaging

Streamline your packaging operations with high-performance vertical baggers d...

Intermittent cartoner for flexible packaging solutions

Enhance your production line’s efficiency with a versatile c...

Vision guided multi-robot system for flowpack candy packaging

Streamline your confectionery packaging process with high-...

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Industrial case rejector for faulty packaging

Ensure product integrity by smoothly removing faulty cases from your product...

Foreign object detection for packaged and unpackaged food

Ensure the integrity of packaged and unpackaged foods by detec...

Hollow wafer spreading machine for consistent coating

Optimize your snack production with precise spreading—achieve unifo...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

Continuous kneader for viscous applications

For engineers tackling high-viscosity challenges, this continuous kneader stre...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Cocoa pressing plant for high-capacity cocoa liquor processing

Optimize your cocoa processing by converting cocoa liquor...

Continuous cocoa bean roaster

Achieve precise flavor profiles in cocoa and nut processing with a continuous roasting solutio...

Cocoa sterilizing and alkalizing plant

Optimize cocoa product quality with a system engineered for precise sterilizing, alk...

Batch conche for chocolate making

Achieve optimal texture and flavor development in your chocolate with precise control ove...

Inline cocoa bean roaster

Streamline your cocoa production by achieving consistent roast quality with precision heat control...

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and l...

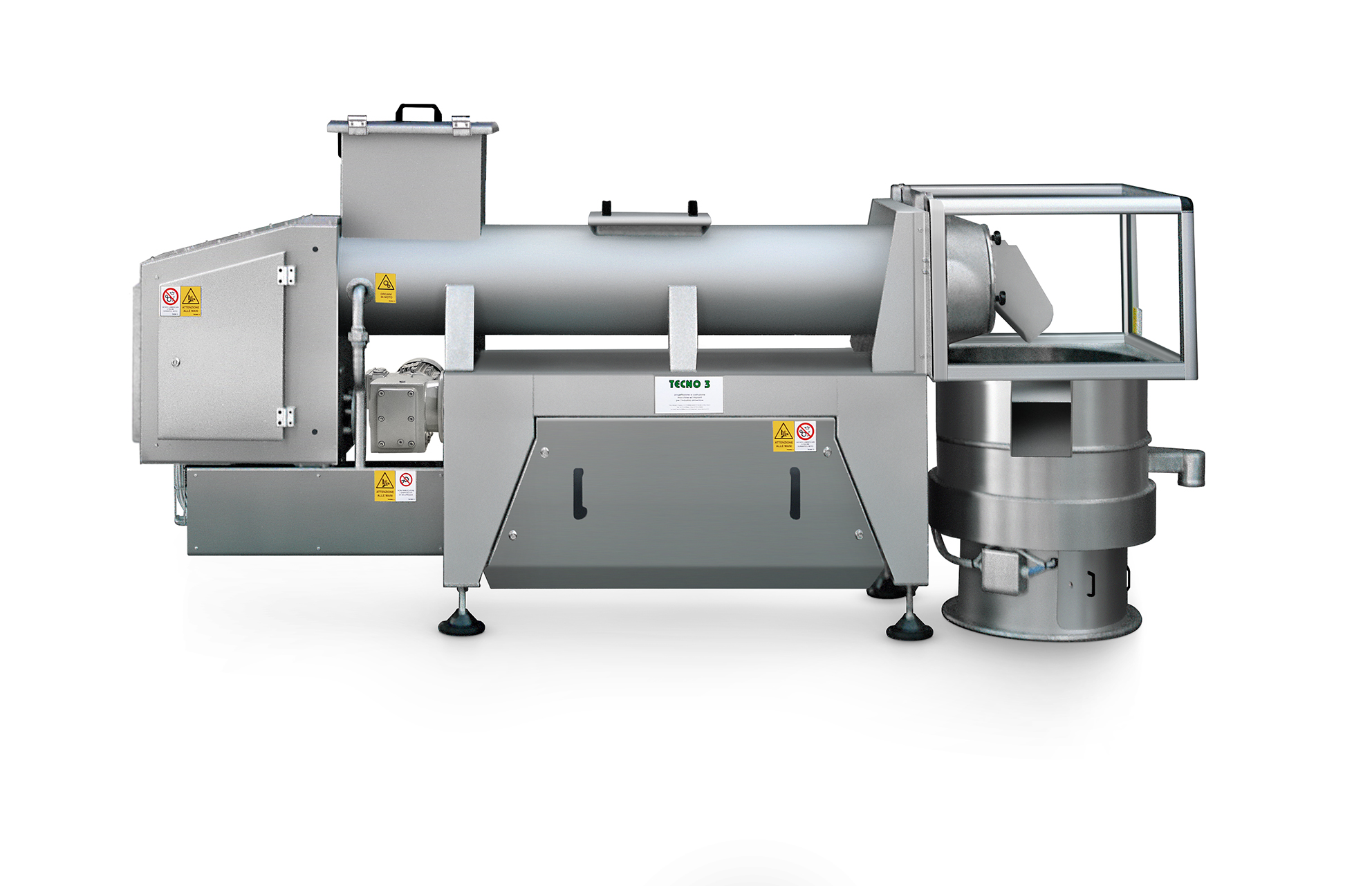

Double shaft batch mixer for chocolate production

Optimize your chocolate and confectionery production with precise mixin...

Pre-refiner for chocolate processing

Optimize pre-refining in chocolate and cocoa production with precise fineness control,...

Chocolate refiner and conche solution

Elevate your chocolate production with a versatile solution that seamlessly integrate...

Chocolate refining five-roll refiner

Achieve optimal chocolate texture with high-efficiency refining, reducing energy usage...

Continuous multi-lane wrapping solution

Achieve precision and speed in packaging with an advanced solution designed for con...

Industrial melting unit for chocolate and powders

Enhance your production efficiency by seamlessly melting and homogenizi...

Scraped surface heat exchanger for high viscous products

Efficiently handle the cooling and heating of high viscous produ...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Vacuum tumblers for food processing

Optimize your production line with vacuum tumblers designed to enhance flavor infusion,...

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

Continuous flow-wrapping system for high productivity

Optimize your packing line with a high-speed flow-wrapping system d...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

Cooling tunnel for confectionery extrusion

Optimize your production line with a versatile cooling tunnel capable of effici...

Confectionery cutting system for accurate results

Achieve precision and flexibility in modern confectionery production wi...

Fermenter for microbial fermentation processes

Optimize your fermentation and biopharmaceutical production with stainless ...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

Horizontal flow pack packaging solution

Achieve seamless packaging with versatile flow pack machines, designed to efficient...

Horizontal flow pack packaging machine for multi-format packaging

Streamline your packaging process with a versatile ho...

Flow pack packaging system for flexible wrapping material

Achieve seamless, high-speed packaging of solid foods with thr...

Flow pack packaging for flexible wrapping material

Achieve precise and secure packaging with three-sided sealed packages ...

Horizontal packaging system for high-speed operations

Achieve unmatched sealing precision and packaging speed with this h...

Compact biscuit depositor for small bakeries

For artisanal producers seeking precision and versatility, this compact equip...

Three-side sealing flow pack machine

Optimize packaging efficiency with a high-speed flow pack machine that ensures precise...

Chocolate, syrup, and fat melting tank

Achieve precise melting and temperature control for chocolate, syrups, and fats, ens...

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

Product counting system for confectionery and food products

Achieve 100% counting accuracy and seamless integration in y...

Product unscramblers for industrial automation

Efficiently organize and orient jumbled products for seamless integration w...

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

Food extruders for pet food production

Achieve precise control in food production with advanced twin screw extruders, desig...

Chocolate mould washer

Ensure immaculate cleanliness and precise drying of chocolate moulds, enhancing production efficiency ...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

Industrial chocolate tempering belt

Achieve precise mass tempering for diverse confectionery textures with a stainless-stee...

Batch weighing system for precise raw ingredient mixing

Optimize your confectionery production with a precise batch weigh...

Hygienic pressure dissolver for high heat exchange

Efficiently dissolve and cook a wide range of confectionery masses wit...

Thin chocolate shell forming

Create gourmet confections with precision by forming delicate chocolate shells, perfect for ver...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

High-speed packaging system for flow-wrapping

Streamline your packaging operations with a high-speed flow-wrapping solutio...

Cut and flow pack system for cylindrical and rectangular pieces

Enhance your confectionery production with a high-speed ...

Flow wrapper for preformed pieces

Optimize your high-speed packaging line with a reliable flow wrapper that seamlessly wrap...

Multilane wrapping solution for food and confectionery products

Enhance your packaging line efficiency with high-speed m...

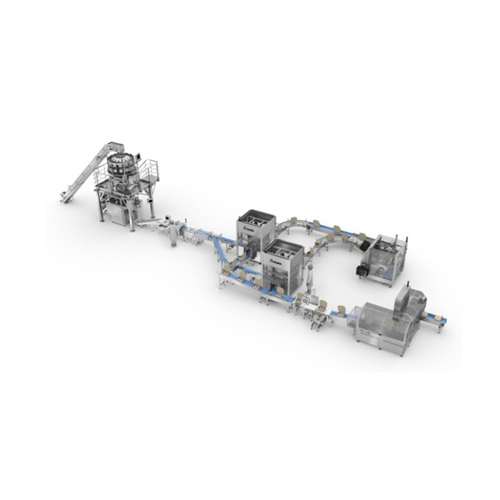

Fully automatic chocolate processing line

Accelerate your chocolate and confectionery production with this high-speed syst...

Laboratory batch chocolate processing unit

Achieve precision in developing chocolate recipes with a compact 3-in-1 unit th...

Chocolate processing unit for mixing, grinding, and conching

Optimize chocolate production with precise mixing, grinding...

Chocolate processing unit for mixing and grinding

Achieve precise mixing and conching efficiency for premium chocolate an...

Tube heat exchanger for chocolate and cocoa liquor

Achieve precise temperature control for chocolate and cocoa processing...

Wet conching system for chocolate production

Achieve optimal chocolate viscosity and flavor by effectively removing volati...

Laboratory conching solution for small batches of chocolate

Optimize your chocolate formulations with precise moisture a...

Ball mill refiner for fine cocoa grinding

Achieve high-precision grinding and refining of chocolates and cocoa with minima...

Automatic chocolate processing line

Transform your production by automating the complete chocolate-making process—from prec...

Ball mill refiner for cocoa liquor and chocolate production

Optimize your cocoa and chocolate refinement with precise gr...

Chocolate processing production line

Efficiently streamline your chocolate and compound production with a fully automatic s...

High-speed continuous motion overwrapper for thin films

For those needing high-speed, efficient wrapping, this equipment ...

Tray and lid forming solution for food packaging

For manufacturers needing precision packaging, this machine seamlessly fo...

Intermittent motion overwrapper for cosmetic and food products

Achieve flawless packaging with precision wrapping and se...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

Wafer block cooling tower

Optimize your confectionery production with seamless wafer cooling, ensuring precise temperature c...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Grain scourer for wheat, durum, and rye

Enhance grain processing by efficiently removing impurities like dust, sand, and so...

One-shot chocolate depositing system

Enhance your confectionery line with precise, high-speed depositing technology designe...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

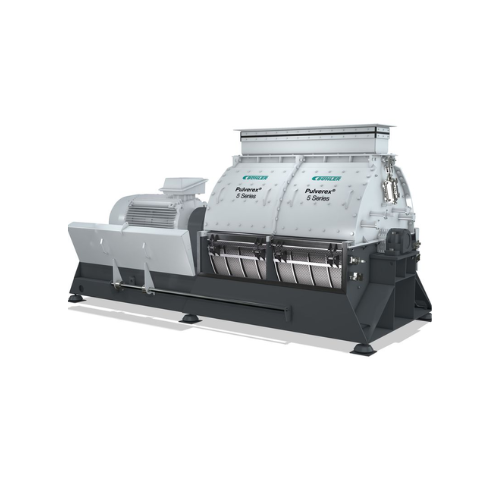

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Ball mill for chocolate, cocoa, and nut products

Optimize your grinding processes and achieve perfect product consistency ...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

Dough sheeter for rotary-cut biscuits

Achieve consistently smooth dough bands essential for high-quality biscuits and confe...

Hybrid tunnel oven for biscuits and cakes

Enhance production efficiency and product consistency with a versatile oven syst...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Double-overthrow conche for chocolate production

Achieve precise taste and texture in chocolate production with reduced en...

Single-shaft conche for chocolate production

Optimize your chocolate production with a conche that delivers shorter conchi...

Chocolate enrober for bars, cookies, and wafers

Ensure consistent and high-quality enrobing for confections with advanced ...

Advanced enrobing line for confectionery

For confectionery producers seeking seamless chocolate coating versatility, our en...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Five-roll refiner for chocolate production

Achieve precise particle size control and energy efficiency in your chocolate r...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Vertical conveyor for bulk materials

Optimize your handling of bulk materials with a cost-effective solution that ensures h...

Continuous moulding line for chocolates

Achieve precise chocolate moulding with continuous operation, ensuring high-speed p...

Loose mould line for chocolate production

Streamline your chocolate production with a high-throughput line that seamlessly...

Optical sorter for wheat applications

Effortlessly enhance product purity by eliminating color defects and foreign material...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Alkalizing system for cocoa powder coloring

Achieve precise cocoa powder coloration and enhanced flavor development with a...

Debacterizing system for cocoa beans

Ensure your cocoa processing meets stringent hygiene standards with this advanced deba...

Infrared pre-treatment system for cocoa beans

Unlock maximum yield and preserve flavor in cocoa processing with this innov...

Cocoa nibs and malt roaster

Achieve precise roasting, sterilization, and taste control of cocoa and malt with adaptable heat...

Winnowing system for cocoa processing

Achieve precise cocoa separation with a high-efficiency winnowing system designed for...

Laboratory winnowing system for cocoa beans

Efficiently crush cocoa beans and separate shells from nibs with precision and...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Chain conveyor for grain handling

Optimize your production line with a customizable chain conveyor that ensures efficient, ...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Integrated grinder for wheat and grain

Achieve superior grinding performance and energy efficiency with this fully integrat...

Cocoa nibs roaster with sterilization control

Achieve precise roasting and sterilization of cocoa nibs and malt with real-...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Lab-scale twin screw extruder

Optimize your material testing and production efficiency with our versatile twin screw extrude...

Coffee roasting system

Optimize your coffee production from green beans to finely ground espresso with this versatile system,...

Flour handling plant for pasta production

Streamline your production with precision handling and processing of flour for p...

Raw material handling systems for plastic and pharmaceutical industries

Effortlessly manage and optimize the handling a...

Material handling system for confectionery production

Optimize your production line with a system designed for efficient ...

Small twin screw extruder

Optimize your lab and pilot production with a versatile twin screw extruder, designed for precise ...

Lab-scale twin screw extruders for material development

Accelerate your formulation testing and material development with...

Lab- and pilot-scale twin screw extruders for small-scale production

Optimize extrusion techniques with lab and pilot-s...

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

Lumps melting system for chocolate and cocoa mass

Efficiently transform solid butter, grease, and chocolate into uniform ...

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Case packing system for bags and cases

Streamline your secondary packaging process with a compact, fully integrated system ...

Vision guided robotics case packer

Maximize efficiency with vision-guided robotics for versatile case and tray loading, red...

Vertical packing pattern case packer

Optimize your packaging efficiency with this high-speed case packer designed for seaml...

Wrap around case packer for horizontal and vertical packing patterns

Optimize your palletizing and distribution with a ...

High-speed case packer for snack bags

Optimize your packaging efficiency with a compact solution designed for seamless vert...

Automated retail ready case closer

Optimize your retail packaging process with a solution that seamlessly seals and closes ...

Horizontal load carton erector for food production

Enhance your production line with precise carton erecting, loading, an...

Semi-auto case packer for flexible bag collation

Enhance your manual packing speed and flexibility with a semi-automatic s...

Flexible bag case packer with integrated case erector

Streamline your secondary packaging process with an efficient solut...

High-speed case packer for flexible bags

Streamline your packaging process with a solution designed for high-speed, error-f...

Horizontal case packing and tray loading

Enhance your packaging line efficiency with a highly adaptive system that seamless...

Vertical case packer for reusable and Rsc cases

Streamline your packaging line with versatile, high-speed case packing tha...

Automatic case forming and sealing solution

Streamline your end-of-line packaging with a solution that forms, folds, and s...

Vision-guided variety pack solution for confectioneries

Achieve seamless variety pack assembly by dynamically loading var...

Retail ready packaging system for easy store stocking

Simplify shelf stocking with a sturdily designed packaging system t...

X-ray and checkweigher combination for medium horizontal products

Streamline your packaging line with integrated checkw...

Combi x-ray inspection and checkweighing for small products

Optimize your production line’s quality control with a...

X-ray inspection for contaminants in horizontal products

Ensure your packaged and unpackaged products are contaminant-fre...

Combi x-ray and checkweigher for vertical products

Ensure precise weight control and contamination detection for vertical...

Integrated metal detector and checkweigher for small/medium formats

Ensure precise quality control and contaminant-free...

Food x-ray inspection system for contaminant detection

Ensure the purity and safety of your food products with advanced x...

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

Wrapper for flat bottomed chocolate articles

Optimize your confectionery packaging with a machine designed for swift, secu...

Neapolitan chocolate wrapping solution

Efficiently wrap and label square chocolates with this fold wrap solution, ideal for...

Pillow bag horizontal form-fill-seal solution

Optimize production efficiency with seamless integration of continuous, high...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Chocolate moulding line for filled and inclusions bars

Achieve seamless chocolate production with modular flexibility, al...

Non-contact accumulator for packaging lines

Experience seamless integration and reduced product interference with this inn...

Compact accumulation conveyor for liquid containers

Optimize your space with an ultra-compact conveyor that ensures seaml...

Automatic wrapping for small products

Achieve precise and efficient packaging of diverse small products with seamless verti...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

High speed horizontal flow wrapper for food products

Achieve precise, high-speed packaging for snacks with this versatile...

Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with vers...

Double twist wrapping solution for candy packaging

Enhance your candy and gum production with high-speed wrapping that en...

Chocolate production belt line

Optimize your chocolate and bakery production with a versatile belt line designed for continu...

Chocolate moulding line for lentils, balls, and eggs

Achieve precision and efficiency in molding chocolate centers for le...

Flexible chocolate moulding line for limited space production

Optimize your production line with a versatile moulding sy...

High capacity chocolate moulding line

Maximize your production capacity with a tailor-made moulding line designed for versa...

Chocolate tempering system

Optimize your chocolate production with a tempering system that achieves precise crystallization,...

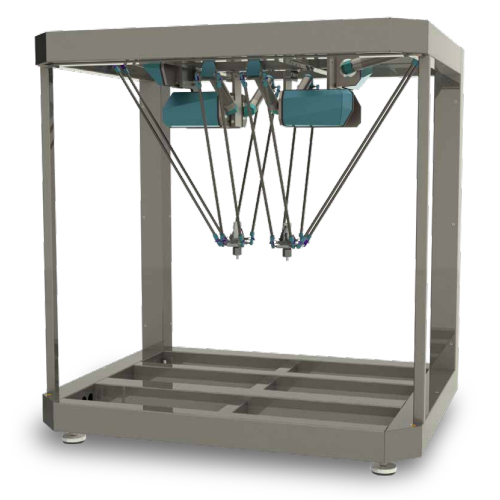

Direct drive delta robots for precision handling

Enhance operational speed and precision with innovative direct drive delt...

Lab-scale chocolate chip depositor

Enhance your R&D capabilities with precision depositing of chocolate masses, allowi...

Chocolate quality analysis instrument

Ensure the highest quality of your chocolate production by precisely measuring contra...

Chocolate temper measurement device

Ensure your chocolate maintains optimal temper by measuring and analyzing the chocolate...

Cooling simulator for chocolate production optimization

Optimize your chocolate cooling processes and refine production s...

Laboratory roller for chocolate production

Easily switch between producing chocolate lentils, balls, and eggs with these f...

Laboratory cold-press chocolate shell maker

Enhance your R&D capabilities with a solution that enables precise cold-p...

Advanced chocolate tempering system

Achieve flawless chocolate and confectionery products with precision tempering, ensurin...

Energy efficient chocolate tempering solution

Enhance your chocolate products with precise temperature control, reducing e...

Chocolate enrober for large scale production

Efficiently enrobe a wide range of products, from chocolate bars to delicate ...

Bottom enrober for chocolate and confectionery products

Optimize your production line with precise bottom enrobing, ensur...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

Small-scale depositor and extruder for bakery production

Revolutionize your confectionery and bakery production with a fl...

Compact extruder and depositor for confectionery and bakery production

Streamline your confectionery and bakery product...

Convection oven for uniform baking

Achieve precise, energy-efficient baking with this convection oven, offering fast heatin...

Flexible depositor and extruder for small-scale production

Achieve precise multi-mass creations with a compact, versatil...

Laboratory chocolate tempering solution

Achieve precise tempering of diverse chocolate and confectionery masses with optimi...

Small-scale chocolate enrober for laboratory use

Optimize small-scale chocolate production with a flexible enrober designe...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Chocolate depositor for small to medium production

Optimize your confectionery production with a versatile depositor that...

Depositor for solid and filled chocolates

Optimize your chocolate production with precision depositing for medium to large...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

Small scale chocolate enrober

Ideal for creative small-scale producers, this enrober allows you to experiment with chocolate...

Energy efficient enrober for chocolate coating

Enhance your production with energy-efficient enrobing that ensures precise...

Enrobing system for rapid changeover in confectionery production

Achieve seamless chocolate coating transitions with a s...

Industrial chocolate enrober

Achieve exceptional chocolate coating consistency and efficiency with this advanced enrobing te...

Conveyor system for chocolate production lines

Streamline your production flow with this conveyor system, ensuring efficie...

Cooling unit for chocolate mass extrusion

Optimize your chocolate production by precisely cooling chocolate masses during ...

Auxiliary feeder mixer for chocolate production

Optimize ingredient incorporation seamlessly with a versatile system that ...

Filling and weighing station for chocolate production

Ensure precise and efficient chocolate mass depositing with a stati...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

Industrial melting tank for chocolate and confectionery production

Maximize your production efficiency by seamlessly in...

Chocolate pump for consistent mass transport

Efficiently transport chocolate mass with precision, ensuring gentle handling...

Cooling tunnel for chocolate and bakery products

Achieve precise cooling and crystallization for chocolate and confectione...

Rotating stencil depositor for confectionery products

Streamline your confectionery operations by precisely depositing in...

Small scale chip depositor for confectionery production

Efficiently deposit a variety of confectionery and snack products...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Dough feeder for flexible and gentle dough handling

Ensure precise, gentle handling and optimal integration with your pro...

Aeration and aroma mixing system for chocolate production

Optimize your chocolate and confectionery production with prec...

Wafer and biscuit feeder for chocolate moulding

Efficiently integrate wafers and biscuits into your chocolate production l...

Chocolate quality measuring instrument

Ensure consistent chocolate quality by accurately measuring contraction, expansion, ...

Robotic chocolate assortment system

Streamline your chocolate production by precisely assorting various filled chocolate ar...

Accurate chocolate tempering measurement tool

Ensure precise chocolate tempering with real-time accuracy, enhancing qualit...

Bi-directional frame scale for industrial weighing

Achieve precise product accumulation and streamlined batch processing ...

Industrial weight tracking system for injected products

Optimize your production line by accurately tracking product weig...

Semi-automatic tray sealing for ready meals

Achieve versatile packaging with a semi-automatic tray sealing solution design...

Automatic tray sealer for high-speed production

Ensure your product packaging stays fresh and secure with this high-capaci...

Industrial case packing solution for high-speed operations

Optimize your production line with a compact, efficient case ...

Bench mounted tray sealer for small-scale production

Perfect for pilot runs and small batches, this compact tray sealer e...

Automatic tray sealer

Maximize throughput and shelf life with our high-speed inline tray sealing solution, ideal for diverse ...

High-capacity tray sealer for vacuum gas packaging

Enhance your production efficiency with a versatile twin-lane tray sea...

In-line tray sealing system

Streamline your packaging line by implementing a high-speed, in-line tray sealing system designe...

Large-capacity automatic tray sealer

Optimize your production line with this tray sealer, designed for high-speed sealing a...

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

Industrial block melt system for butter and chocolate

Efficiently transition solid blocks of butter, chocolate, or waxes ...

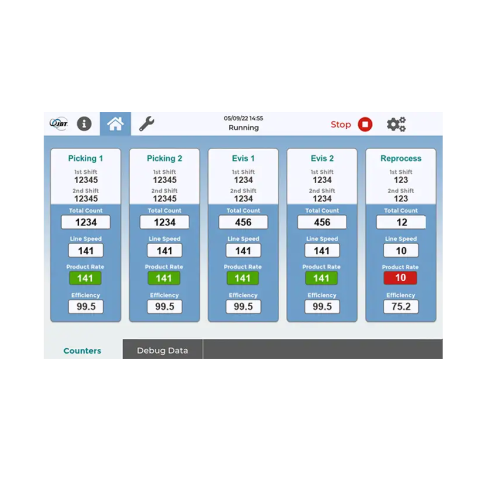

Poultry processing efficiency monitoring system

Maximize production efficiency with real-time monitoring and precise track...

Spiral freezer for bakery and confectionery

Maximize space and efficiency while preserving the quality and freshness of di...

Meat portioning and slicing system for precision cuts

Streamline your production process with precise portioning and slic...

Rotary tablet press for abrasive powders

Achieve precise tablet sizing and bilayer production, even with abrasive powders, ...

Finished product storage silos for industrial applications

Optimize your storage capabilities with silos that ensure saf...

Product distribution system for large capacity wrappers

Optimize your high-speed production lines by efficiently distribu...

Robotic pick and place system for cookies

Streamline your bakery production with a flexible robotic system that seamlessly...

Product manipulation and stacking systems

Efficiently transition products from flat to stacked on a conveyor while minimiz...

Fifo inflow buffer for efficient production lines

Optimize your production flow with a solution that seamlessly absorbs d...

Tray buffering system for downstream absorption

Handle production line disruptions effortlessly by temporarily absorbing t...

High-volume product distribution system

Efficiently manage high-volume snack and confectionery production flows with a syst...

Conveyor system for ambient product cooling

Ensure precise cooling of baked and confectionery products while maintaining l...

Large production autoclaves for laboratory and pharmaceutical use

Enhance your production line with our large autoclave...

High-speed checkweigher for dynamic weighing

Achieve precision and consistency in high-speed production environments with ...

Checkweigher and metal detector for heavy loads

Streamline your inspection process by combining precision weighing with co...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

High-speed mixer for homogenous mixing of powders and pastes

Achieve rapid and precise mixing with high-speed dispersion...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Air cannons for resolving bulk material flow issues

Solve bridging and rat-holing issues in bulk material storage with po...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

Rotary roller vibrators for concrete compacting and hopper emptying

Achieve higher compaction and efficient emptying wi...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Anti-wear elbows for pneumatic conveying systems

Reduce wear and extend the lifespan of your pneumatic conveying systems w...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Food-grade bin activator for optimized material flow

Ensure hygienic and efficient discharge from hoppers with our food-g...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Agitator for horizontal storage tanks

Efficiently blend various viscosities in horizontal tanks, ensuring optimized flow pa...

Industrial side-mounted agitator for efficient mixing

Enhance your production line with a side-entry agitator designed fo...

Laboratory stirrer for research and small-scale production

Optimize your research and scale up your production with a ve...

Laboratory and production agitator for medium-sized containers

Streamline your mixing and agitation processes with a ver...

Industrial mixer for facade paint and plaster

Optimize your facade paint and plaster production with this mixer designed f...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Continuous motion vertical form fill seal packaging system

Achieve high-speed, consistent packaging for diverse products...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for eff...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Conveyor belts for hot and cold product handling

Efficiently transport hot and cold goods with versatile conveyor solution...

Sausage linking and portioning solution

Optimize your sausage production with precise linking, hanging, and cutting technol...

Industrial pressing system for convenience food

Optimize your production line with a versatile pressing system, designed t...

Stainless steel trolley for industrial use

Streamline material handling and storage in food processing operations with a v...

Clean-in-place (cip) system for sanitation processes

Ensure thorough sanitation in your production line with a streamline...

Stainless steel centrifugal pump for liquid transfer

Optimize your food and dairy production with a reliable centrifugal ...

Industrial dicer for small to intermediate size ranges

Boost your production capacity with a versatile dicing solution th...

Storage tank integrity testing

Prevent costly contamination and streamline your operations with advanced tank integrity test...

Industrial depositor for automated recipe management

Effortlessly streamline your production with precise depositing cont...

Side seal shrink packaging machine

Achieve seamless and efficient packaging for varied product sizes with continuous side s...

High-speed Map packaging for fresh food products

Ensure product freshness and safety with robust, high-speed packaging tha...

Horizontal flow wrapper for bakery and chocolate

Achieve seamless integration in high-speed production lines with a horizo...

Automatic hamburger packaging solution

Streamline your hamburger production with a fully automated packaging system that en...

Automated bagging system for confectionery products

Achieve seamless integration in your confectionery packaging line wit...

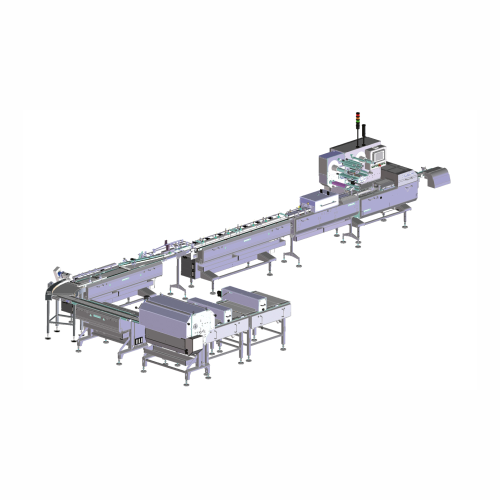

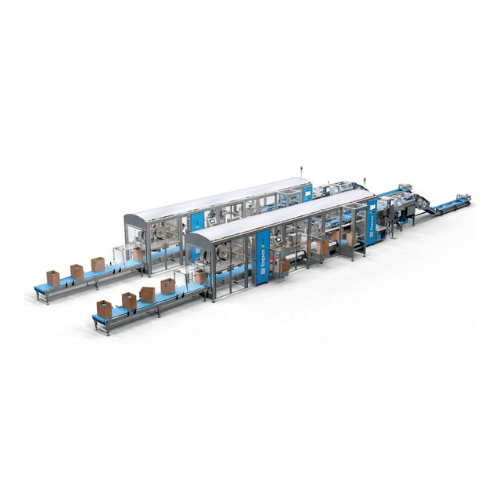

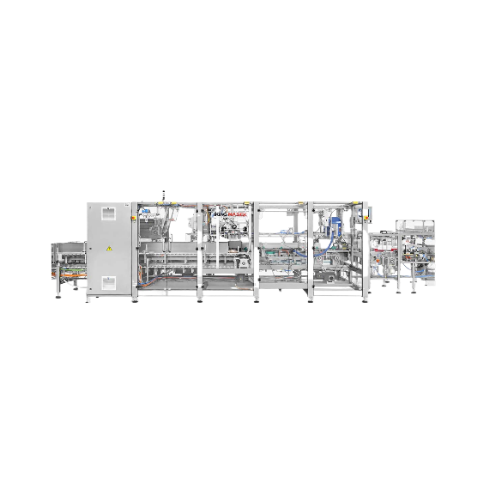

Complete primary and multipack packaging solution for bars

Enhance your bar production efficiency by seamlessly integrat...

Sweet baked goods packaging solution

Optimize your sweet baked goods packaging process with a fully automated solution desi...

Automated line for baked goods packaging

Enhance your packaging efficiency with a seamless integration of precise loading a...

Box cartoning solution for single bricks and bar packages

Efficiently collate and seal brick or bar-shaped products into...

Single and dual lane sorters for fresh produce

Optimize your food processing line with precision defect detection and vers...

High sensitivity metal detectors for food products

Ensure food safety and product quality by effectively detecting and re...

X-ray detection for food inspection

Ensure product integrity in high-speed packaging lines by detecting metallic and non-me...

Industrial metal detector for food and beverage applications

Ensure your production line is free from metal contaminants...

Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating ...

Overflow conveyor for efficient product handling

Streamline your production with overflow conveyors that manage excess pro...

Plate and counter mould storage system for confectionery products

Streamline your confectionery production with an effi...

Row aligner for product packaging

Optimize your packaging line with precise alignment and high-speed product handling, ensu...

Vision-based robotic feeding system

Enhance your production line with precise robotic feeding, optimizing product placement...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

High-speed forming, cutting, and wrapping for side and bottom folds

Streamline your confectionery production with a mac...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

Accumulation conveyor for controlled feeding in packaging lines

Ensure seamless product flow and enhance efficiency in y...

Cross transfer station for mould configuration products

Streamline the transfer of mould-configured products across your ...

Curved conveyor for product transport

Streamline your product flow with a versatile curved conveyor, perfect for maintainin...

Flexible high-speed wrapping machine for chocolate products

Optimize your confectionery production line with a flexible ...

High speed fold wrap and stick packs packaging system

Enhance your confectionery production line with a packaging system ...

High speed packaging system for soft caramels

Optimize your confectionery line with a high-speed solution designed to seam...

High-speed wrapping machine for chocolate or compressed powder products

For confectionery and pharmaceutical operations...

Modular high-speed wrapper for chocolate flow packs

Efficiently wrap a wide range of products, from chocolate bars to dis...

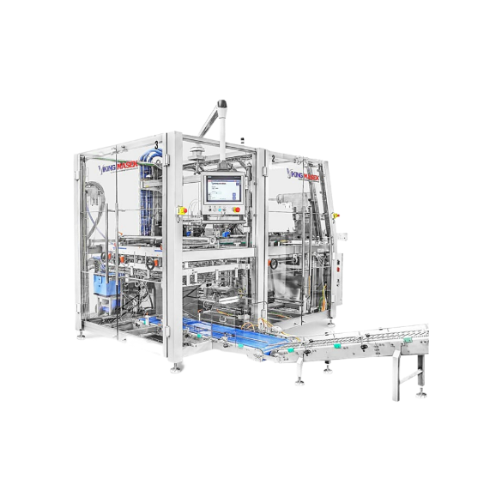

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

High-speed wrapping system for chocolate bars

Ensure quick and precise packaging for chocolate bars with a high-speed syst...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Retrofit package for Ek1 packaging system

Upgrade older packaging systems to enhance efficiency and flexibility while acco...

High-speed wrapping solution for preformed candies

Ensure consistent wrapping of diverse confectionery products with a hi...

Food production metal detector for packaged products

Ensure product safety and compliance by detecting metal contaminants...

Industrial metal detector for packaged food products

Ensure the safety and compliance of your packaged food products by d...

Horizontal form-fill-seal systems for pouch packaging

For production lines that demand efficient pouch creation, these hi...

Industrial washing solutions for crates, bins, and pallets

Optimize hygiene in your production line with advanced washin...

Combined metal detector and checkweigher for food production

Ensure compliance and safety in food production with this i...

Centrifugal pump station for chocolate coating applications

Ensure precise temperature control and efficient chocolate c...

Modular high-speed flow pack wrapper for preformed products

Eliminate packaging line bottlenecks with a versatile high-s...

Cleaning in place solution for food production systems

Optimize your cleaning process with an integrated clean-in-place s...

Cocoa bean peeling solution

Enhance your cocoa and coffee production with efficient peeling, reducing waste and ensuring hig...

Pure water generation system for pharmaceutical manufacturing

Ensure high-purity water and steam production with precisi...

Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper tha...

Paper forming technology for sustainable packaging

Elevate your product’s sustainability with advanced paper formin...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Industrial bag sealing solution for medical and food applications

Enhance your packaging line with reliable and versati...

Case packer for diverse food products

Optimize your packaging line with this versatile case packer, capable of handling a w...

Laser-based volume measurement for bakery and solid products

For precision in product quality control, this laser-based ...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Lay-on systems for precise sprinkling and nut depositing

Optimize your confectionery production with precision sprinkling...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Portable chocolate tempering degree checker

Ensure precise chocolate tempering to enhance product quality and consistency,...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Industrial enrobing solution for quality coatings

Achieve high-quality coatings for pralines, bars, and pastries with a c...

Compact chocolate enrobing system

Achieve perfect chocolate coatings in minimal space with precise control, enabling high-q...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Enrobing system for biscuits and baked goods