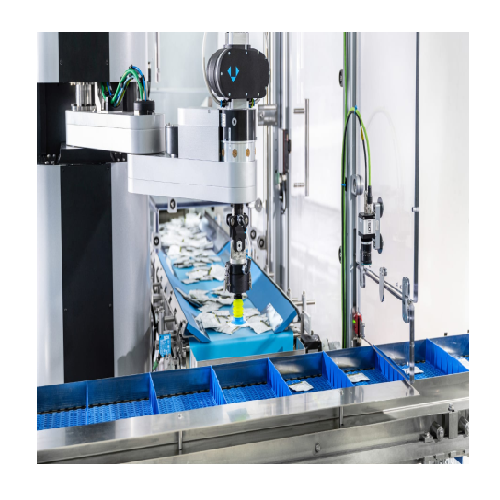

Automated pick and place cobot for packaging

Overcome packaging bottlenecks with an advanced cobot designed for high-speed, flexible integration, ideal for automating manual feeding tasks efficiently.

Automates Packaging Processes with AI Precision

The tog.519 Cobot from Schubert represents a pivotal advancement in packaging automation. Engineered to overcome challenges in manual feeding, this cobot integrates seamlessly into existing packaging lines, accommodating a wide array of industries such as food, pharmaceuticals, and cosmetics. It enhances production flexibility and speed by utilizing an AI-supported vision system for precise pick-and-place tasks while handling unpredictable product assortments effortlessly. Capable of assembling packaging materials and products without additional programming, the tog.519 ensures an adaptable workflow, ideal for both solid and liquid products. This cobot exemplifies energy efficiency with its streamlined motor control and offers robust corrosion-resistant materials for enduring performance across diverse operational environments. Communicating effortlessly with other equipment and requiring minimal setup, it allows manufacturers to scale dynamically according to production demands, greatly minimizing downtime and maximizing output efficiency.

Benefits

- Streamlines labor-intensive manual feeding operations, reducing workforce dependency.

- Enhances production line agility with fast, flexible adaptation to new products and formats.

- Reduces setup and reconfiguration time with plug-and-play capability.

- Maintains consistent packaging quality through AI-supported precision handling.

- Supports sustainable operations with minimized energy usage and waste.

- Applications

- Food, Beverages, Snacks, Pet food, Confectionery, Cosmetics, Pharma, Bakery products, Technical articles, Dairy

- End products

- Electrical components, Face creams, Tablets, Soda bottles, Kibble, Chips, Yogurt cups, Chocolate bars, Croissants, Ready-to-eat meals

- Steps before

- Product Sorting, Material Preparation, Component Assembly

- Steps after

- Quality Inspection, Sealing, Labeling

- Input ingredients

- unsorted products, boxes, trays, pucks, jars, bottles, packaging materials, intermediate layers

- Output ingredients

- filled boxes, filled trays, prepared packaging components, completed products with pumps and lids

- Market info

- Schubert Group is renowned for its innovative packaging technology solutions, specializing in modular, highly flexible packaging machines for various industries, ensuring efficiency and precision in production lines.

- Speed

- Faster than commercially available collaborative robots

- Automation

- Digitalised automation for manual feeding tasks

- Programming

- Extremely easy to program

- Mobility

- Mobile

- Vision System

- AI-supported

- Handling Flexibility

- Handles unsorted products and multiple formats

- Robotics Performance

- High-tech and easy to operate

- Communication

- Does not require communication with downstream machines

- Component Integration

- Open interfaces for easy integration

- Product Types

- Processes diverse products

- Setup Time

- Quick set up with plug, play

- Environmental Flexibility

- Adapts to changes in production, seasonal products, or peaks

- Automation level

- Manual / PLC / SCADA

- Changeover time

- Short / Fast

- CIP/SIP

- Not typically required

- Cleaning method

- Manual / Easy clean

- Energy efficiency

- Low energy consumption

- Mobility

- Mobile / Stationary

- Programming ease

- User-friendly / No programming knowledge required

- Setup time

- Quick setup

- Integration capability

- Easy integration with existing systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Mobile

- Yes

- Easy to program

- Yes

- Discharge method

- Pick, Place

- Control panel type

- Touchscreen

- Control panel type

- Touchscreen / PLC interface

- Integration possibilities

- AI-supported vision system / Open interfaces for third-party integration

- Programming requirements

- No additional robotics expertise required

- Mobility

- Mobile design

- Tool compatibility

- Exchangeable tools for flexibility

- Programmability

- Extremely easy to program

- Operational flexibility

- Handles new products directly

- Station adjustability

- Quick adjustment for production peaks