Row aligner for product packaging

Optimize your packaging line with precise alignment and high-speed product handling, ensuring seamless integration and improved efficiency for confectionery and food processing operations.

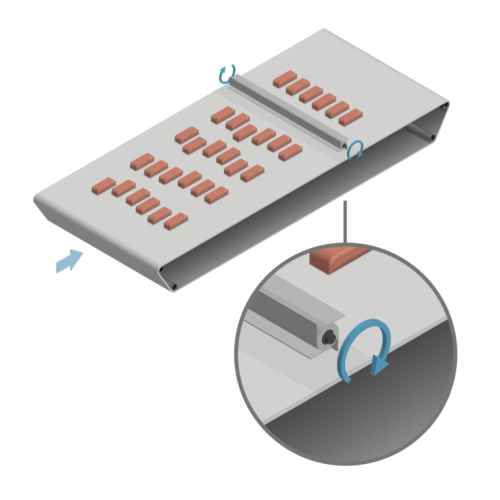

Aligns and Transfers Solid Products Efficiently

The Row Aligner from Theegarten-Pactec is a versatile solution for confectionery and food packaging companies, designed to align solid products with precision. Utilizing either pneumatic or servo motor-driven operations, this aligner can handle up to 120 rows per minute, efficiently integrating into existing production lines. It facilitates the orderly transfer of chocolate bars, caramel squares, and an array of other confectioneries and non-food items such as dishwasher tablets, enhancing downstream packaging capabilities.

The Row Aligner’s design ensures seamless product alignment and transfer via smooth conveyor systems, equipped with a three-phase motor and frequency controller for optimal performance. Its easy-to-clean structure, featuring removable swiveling safety covers and conveyor support plates, minimizes downtime for maintenance. Built with pneumatic web tracking control and quick tensioning devices, the aligner promises reduced energy usage and efficient handling.

Ideal for both high-speed and continuous operations, the Row Aligner offers customization to meet specific production needs. Its robust construction is complemented by engineering support for tailored integration, making it an essential component for those aiming to streamline their packaging processes.

Benefits

- Increases packaging line efficiency with precise product alignment, reducing potential bottlenecks.

- Supports high-speed operations up to 120 rows per minute, maximizing production throughput.

- Facilitates quick maintenance with easy access and cleaning features, minimizing downtime.

- Optimizes energy consumption with integrated frequency controllers, contributing to cost savings.

- Customizable design provides flexibility for diverse production needs, enhancing operational adaptability.

- Applications

- Chewy sweets, Soft caramels, Bouillon cubes, Hard candies, Effervescent tablets, Fudge, Chocolate products, Bubble gum, Toffee, Jelly products, Eclairs, Dishwasher tablets, Preformed products, Krówki, Chewing gum

- End products

- Fudge squares, Gummy bears, Eclairs with cream filling, Polish krówki candies, Effervescent vitamin tablets, Molded confectionery, Caramel squares, Chocolate pralines, Nougat bites, Chocolate bars, Bubble gum balls, Chicken bouillon cubes, Lemon-scented dishwasher tablets, Toffee chewables, Chewing gum sticks, Fruit-flavored hard candies

- Steps before

- Product Processing, Conveyor Belt Loading, Product Sorting

- Steps after

- Packaging, Product Wrapping, Automatic Distribution

- Input ingredients

- chocolate products, hard caramels, jelly products, chocolate balls, eggs, bouillon cubes, cereals, chewing gum, bubble gum products, chewy sweets, dishwasher tablets, eclairs, effervescent tablets, krówki, soft caramels, toffee, fudge

- Output ingredients

- aligned rows of products, packaged products

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Capacity (Pneumatically)

- Up to 90 rows per minute

- Capacity (Servo driven)

- Up to 120 rows per minute

- Automation

- Servo motor/Pneumatically

- Cleaning Access

- Easy access through removable swiveling safety covers

- Motor Type

- Three-phase motor driven conveyor

- Frequency Control

- Integrated within the switch cabinet

- Pneumatic Web Tracking Control

- Yes

- Conveyor Maintenance

- Quick tensioning devices

- Product Transfer

- Smooth with 10 mm return shafts

- Automation level

- Pneumatic / Servo motor driven

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Easy access with removable covers

- Changeover time

- Quick tensioning devices

- Product alignment

- Right angles to product flow

- Capacity

- Up to 90 rows/min (Pneumatic), up to 120 rows/min (Servo)

- Abrasion resistance

- Pneumatic web tracking components

- Cleanability

- Removable swiveling safety covers

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Density/particle size

- Flexible handling of various product sizes

- Alignment method

- At right angles to direction of product flow

- Drive type

- Pneumatically / Servo motor driven

- Capacity

- Pneumatically

- Conveyor

- Three-phase motor driven, frequency controlled

- Cleaning access

- Removable swivelling safety covers, removable conveyor support plates

- Product transfer

- All product transfers with underneath sliding waste trays

- Return shaft diameter

- 10 mm

- Conveyor belt maintenance

- Quick tensioning devices for easy maintenance and service

- Power Source

- Pneumatic / Servo motor driven

- Capacity

- Pneumatically

- Conveyor System

- Three-phase motor / Frequency controller integrated

- Cleaning Access

- Removable swivelling safety covers / Removable conveyor support plates

- Maintenance Features

- Quick tensioning devices for conveyor belts

- Product Transfer

- Smooth product transfer with return shafts diameter 10 mm