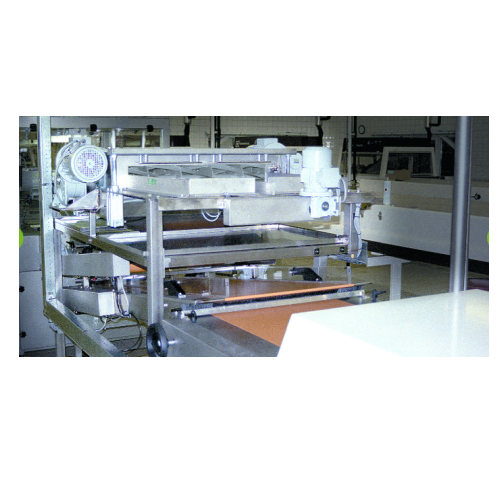

Industrial chocolate flakes production equipment for decorative applications

Achieve perfect decorative chocolate curls and flakes with tailored precision, enhancing your confectionery and bakery creations while seamlessly integrating into existing production lines for high-speed, continuous operation.

Produces Uniform Chocolate Curls and Flakes

The Industrial Curl Chocolate Flaking Machine by Prefamac Chocolate Machines offers a precise solution for chocolate manufacturers and confectionery producers looking to enhance their decorative product lines. This machine excels in transforming solid chocolate blocks into uniform curls and flakes through a high-speed curling and flaking process. Designed for continuous operation, it integrates seamlessly into existing truffle lines and can be configured with a Prefamac conveyor belt or cooling tunnel for optimal product quality. Tailored blade configurations allow producers to achieve various flake lengths, while adjustable motor speeds offer control over thickness without losing the distinctive curl shape. Ideal for applications such as truffle coatings and bakery toppings, this machine accommodates demanding production volumes through expansion capabilities, ensuring adaptability to your operational needs. Its robust construction and engineering support ensure minimal maintenance and maximum uptime, supporting large-scale production demands efficiently.

Benefits

- Enhances product appeal with consistently uniform decorative chocolate curls.

- Increases production efficiency through high-speed, continuous operation.

- Flexible customization options accommodate diverse flake lengths and thickness requirements.

- Seamless integration with cooling tunnels preserves shape and quality of curls.

- Adaptable design allows for easy expansion to meet high production demands.

- Applications

- Confectionery, Sweets, Cakes, Bakery products, Chocolate, Truffles

- End products

- Confectionery decorations, Chocolate curls, Truffle coatings, Decorative chocolate flakes for cakes, Bakery topping flakes

- Steps before

- Block Chocolate Preparation, Chocolate Cooling

- Steps after

- Cooling, Packing, Decorative Application

- Input ingredients

- chocolate blocks, blocks of chocolate

- Output ingredients

- chocolate flakes, curl chocolate flakes, decorative chocolate flakes

- Market info

- Prefamac is known for manufacturing high-quality chocolate processing equipment, including tempering, enrobing, and cooling machines. The company is recognized for innovative and custom-engineered solutions tailored to the confectionery industry, emphasizing precision, efficiency, and reliability.

- Flake Thickness

- Adjustable

- Flake Length

- Variable

- Block Capacity

- 2 blocks of 5 kg

- Speed

- High

- Automation

- Adjustable motor speed

- Connection Options

- Conveyor belt/truffle line

- Cooling Integration

- Prefamac cooling tunnel

- Working Mechanism

- Flaking of chocolate blocks

- Batch vs. Continuous Operation

- Batch operation

- Integration Options

- Truffle line, conveyor belt, cooling tunnel

- Automation Level

- Motor speed adjustable

- Cooling Requirement

- Cooling tunnel connection

- Customization

- Tailor-made

- Abrasion resistance

- Yes

- Biological compatibility

- Food-grade

- Cleanability

- CIP compatible

- Corrosive resistance (e.g. acids)

- Stainless steel structure

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design for integration on truffle line or conveyor

- Chocolate block capacity

- 2 blocks of 5 kg

- Assembly configuration

- Pairs opposite each other in frame

- Integration

- Connectable to Prefamac conveyor belt or cooling tunnel

- Flake length variation

- Adjustable by blade type and motor speed

- Cooling integration

- Recommend connection to cooling tunnel

- Customization

- Tailor-made configurations available

- Integration possibilities

- Prefamac conveyor belt / cooling tunnel

- Blade customization

- Multiple blades for different flake lengths

- Control panel type

- Adjustable motors for flake thickness

- Expansion capability

- Expandable to 8 sets of 2 blocks simultaneously