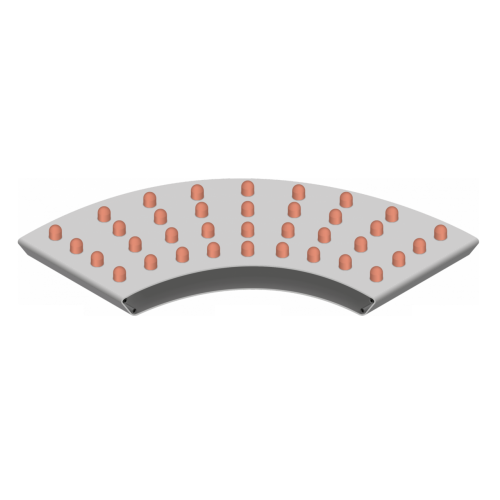

Curved conveyor for product transport

Streamline your product flow with a versatile curved conveyor, perfect for maintaining row structure and ensuring seamless transport through complex production layouts.

Transports and Transfers Solid Products Efficiently

The Curved Conveyor from Theegarten-Pactec offers a sophisticated solution for food and confectionery transport challenges. With the ability to navigate up to 180° curves, this conveyor ensures seamless integration into existing production lines with varied layouts. Designed for high-speed operations, it efficiently handles solid products like chocolate bars and hard candies while maintaining structural integrity during transport. Equipped with a three-phase motor and an integrated frequency controller, the conveyor optimizes energy consumption and provides precise control over product flow. Accessible cleaning features, including removable support plates and quick tensioning devices, contribute to reduced downtime and ease of maintenance. Built from durable materials, this conveyor is suitable for rigorous operational conditions within the food and confectionery industries.

Benefits

- Ensures efficient product transport with minimal disruption to row structure, enhancing line consistency.

- Reduces maintenance downtime through easy-clean removal support plates and quick belt tensioning.

- Optimizes energy usage with an integrated frequency controller for cost-effective operations.

- Adapts easily to various production layouts with flexible inner radius design.

- Supports high-speed, continuous operations, elevating overall production efficiency.

- Applications

- Chewy sweets, Soft caramels, Bouillon cubes, Effervescent tablets, Hard candies, Eclairs, Fudge, Chocolate products, Toffee, Cereals, Jelly products, Bubble gum products, Dishwasher tablets, Preformed products, Krówki, Chewing gum

- End products

- Instant oatmeal packets, Chocolate truffles, Soft caramel cubes, Krówki candy, Preformed chocolate easter eggs, Toffee squares, Dishwasher pods, Hard candy lozenges, Gummy bear sweets, Fudge bites, Soft candy chews, Chocolate bars, Bouillon cube packs, Chewing gum pellets, Éclair pastries, Effervescent vitamin tablets, Bubble gum strips

- Steps before

- Processing Plant Transfer, Layout Configuration

- Steps after

- Distribution to Packaging Machines, Product Flow Division, Row Structuring, Packaging, Cross Transfer Station, Lane Arrangement

- Input ingredients

- bouillon cubes, cereals, chewing gum, bubble gum products, chewy sweets, chocolate products, dishwasher tablets, eclairs, effervescent tablets, hard candies, preformed products, jelly products, krówki, soft caramels, toffee, fudge

- Output ingredients

- packaged bouillon cubes, packaged cereals, packaged chewing gum, packaged bubble gum products, packaged chewy sweets, packaged chocolate products, packaged dishwasher tablets, packaged eclairs, packaged effervescent tablets, packaged hard candies, packaged preformed products, packaged jelly products, packaged krówki, packaged soft caramels, packaged toffee, packaged fudge, bulk chocolate products distribution, individual chocolate products blocks, lanes of chocolate products, packaged hard caramels, packaged jelly products, packaged chocolate balls, packaged chocolate eggs

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Conveyor Type

- Curved Conveyor

- Conveyor Angle

- Up to 180°

- Motor Type

- Three-phase motor

- Automation

- Frequency controller integrated

- Cleaning Access

- Removable conveyor support plates

- Maintenance Features

- Quick tensioning devices for conveyor belts

- Product Transfer

- Transport without destroying row structure

- Return Shaft Diameter

- 10 mm

- Design Flexibility

- Flexible inner radius

- Working mechanism

- Curved feeding up to 180°

- Automation level

- Three-phase motor driven with frequency controller

- Cleaning method

- Easy access through removable conveyor support plates

- Changeover time

- Quick with tensioning devices for belts

- Product transfer

- Smooth with 10 mm diameter return shafts

- Flexible design

- Inner radius customization

- Abrasion resistance

- Yes

- Cleanability

- Removable conveyor support plates

- Heat sensitivity

- Chocolate Products, Soft Caramels

- Form stability

- Hard Candies, Preformed Products

- Viscosity

- Soft Caramels, Toffee, Fudge

- Fragility

- Chocolate Balls and Eggs

- Curved Conveyor Angle

- Up to 180°

- Conveyor Width

- Different widths available

- Conveyor Height

- Flexible heights

- Inner Radius Design

- Flexible design

- Product Transfer Method

- Smooth transfer with 10 mm return shafts

- Conveyor Belt Tensioning

- Quick tensioning devices

- Conveyor Support Plates

- Removable for easy cleaning

- Motor Type

- Three-phase motor with frequency controller

- Curved angle

- up to 180°

- Width variants

- Different widths available

- Height adjustments

- Different heights available

- Inner radius design

- Flexible

- Conveyor belt tension

- Quick tensioning devices