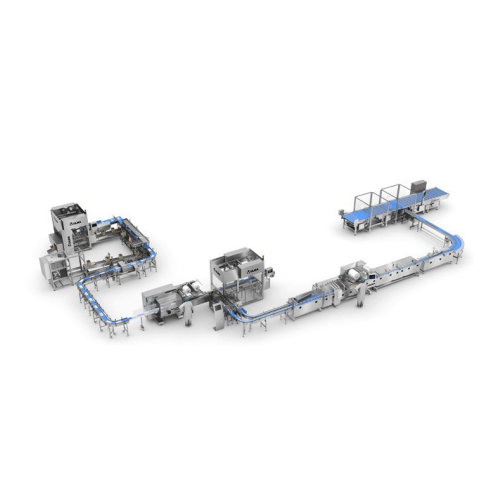

Complete primary and multipack packaging solution for bars

Enhance your bar production efficiency by seamlessly integrating high-speed primary and multipack packaging, ensuring product integrity and consistent output for diverse confectionery and snack options.

Packs, Wraps, Distributes, Indexes, Groups, and Loads

The complete solution for primary and multipack packaging of bars from ULMA Packaging offers a fully automated, high-speed system specifically designed for the food and confectionery industry. This equipment efficiently manages the flow packing, thermoforming, and tray sealing processes, ensuring seamless integration into your existing production line. It operates through a sophisticated sequence of distribution, indexing, grouping, and loading, culminating in precise case erection for various bars and packaged goods.

Targeting applications such as protein bars, granola bars, chocolate bars, and multipacks of baked goods and snacks, this system is ideal for food manufacturers, confectionery producers, and packaged goods businesses. With a robust flow pack mechanism and a flexible, multi-format case erector, it streamlines packaging while allowing for quick format changes for diverse product lines.

The equipment features a PLC-controlled automation system, ensuring reliable performance and compatibility with remote monitoring for continuous operation. Its energy-efficient design reduces consumption, making it not only cost-effective but also environmentally friendly. ULMA Packaging supports customization and offers engineering assistance to tailor the equipment to your specific production needs, providing an integrated solution that enhances efficiency and product throughput.

Benefits

- Enhances packaging efficiency through integrated flow and case erection, minimizing manual intervention.

- Supports diverse product lines with quick format changes, accommodating various bar and confectionery sizes.

- Increases production speed through high-throughput operation, optimizing output per shift.

- Reduces energy costs via energy-efficient motor designs and optimized automation.

- Facilitates seamless integration with existing systems, promoting production line continuity.

- Applications

- Biscuits, Snacks, Bakery, Confectionery, Bars

- End products

- Baked goods multipacks, Energy bars, Mixed nuts packs, Cookie assortments, Granola bars, Potato chips packs, Popcorn packs, Cereal bars, Candy bars, Chocolate bars, Chocolate confectioneries, Biscuit packs, Protein bars

- Steps before

- Orientation, Rows distribution

- Steps after

- Secondary packaging, Case packing, Multipack grouping

- Input ingredients

- naked product, rows of product, singles bars, linear products

- Output ingredients

- flow wrapped products, unitary packs, multipacks, formed empty boxes, secondary packaging

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation

- Fully automated

- Flow wrap speed

- High-speed

- Multipack capability

- Automatic groupings

- Case erector flexibility

- Multi-format

- Format change

- Automatic

- Robotic cell streams

- Two streams

- Packaging type

- Primary and multipack

- Working mechanism

- Automatic line with robotic integration

- Integrated steps

- Primary and multipack packaging

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous inline operation

- Changeover time

- Automatic format change

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Bar size

- Small / Medium / Large

- Packaging type

- Primary / Multipack

- Product orientation

- Flat / Upright

- Grouping configuration

- Customizable

- Feed method

- Automatic

- Discharge method

- Automatic case packing

- Control panel type

- Automated

- Control panel type

- Touchscreen

- Integration possibilities

- PLC/SCADA systems

- Multi-format capability

- Automatic format change

- Packaging configuration

- Single and multipack