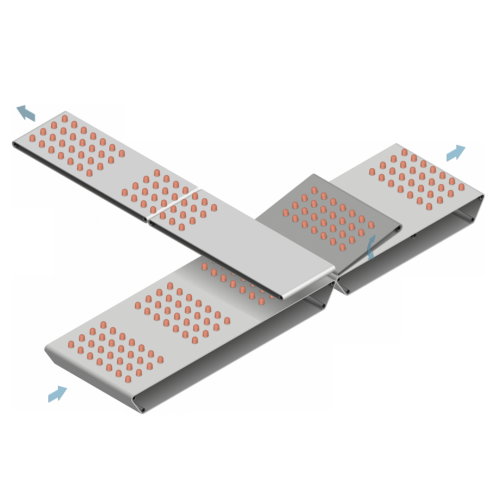

Cross transfer station for mould configuration products

Streamline the transfer of mould-configured products across your production line with seamless integration, ensuring efficient flow and precise distribution to packaging machines.

Transfers and Distributes Mould-Configured Products Efficiently

The Cross Transfer Station for Mould Configured Product Handling, developed by Theegarten-Pactec, is designed to seamlessly integrate into food and confectionery manufacturing lines. This system efficiently transfers and distributes products like chocolate bars, lollipops, and bouillon cubes. Utilizing oscillating and moveable conveyors driven by three-phase and servo motors, it ensures high-speed, continuous operation with precise control. The station caters to complex packaging needs by optimizing product flow from the main conveyor to various packaging machines. With features like pneumatic web tracking and quick tensioning devices, it minimizes downtime and energy consumption. Customizable stages allow for integration with existing processing plants and storage systems, making it a versatile solution across multiple industries. The design ensures easy access for maintenance and cleaning, backed by Theegarten-Pactec’s engineering support for tailored solutions.

Benefits

- Enhances efficiency by ensuring precise product placement with minimal manual handling.

- Reduces operational costs with energy-efficient servo and three-phase motor-driven systems.

- Minimizes maintenance downtime through easy-access cleaning and quick conveyor belt tensioning.

- Increases flexibility with customizable integration options for existing production and storage setups.

- Supports high-speed operations, optimizing throughput for diverse product handling applications.

- Applications

- Chewy sweets, Soft caramels, Bouillon cubes, Hard candies, Fudge, Eclairs, Chocolate products, Bubble gum, Cereals, Toffee, Jelly products, Effervescent tablets, Dishwasher tablets, Preformed products, Krówki, Chewing gum

- End products

- Filled eclairs, Strawberry chews, Jelly beans, Chocolate fudge, Mint gum, Pressed dishwashing powder tablets, Chocolate truffles, Salted toffee, Chicken bouillon cubes, Fruity bubble gum, Soft toffee caramels, Cornflakes, Flavored granola, Gummies, Beef bouillon cubes, Candy tablets, Soft chew caramels, Chocolate eggs, Chocolate bars, Polish krówki, Lollipops

- Steps before

- Mould Configuration, Product Processing, Main Conveyor Transfer

- Steps after

- Feeding to Packaging Machines, Automatic Distribution, Packaging

- Input ingredients

- products in mould configuration, chocolate products, hard caramels, jelly products, chocolate balls, chocolate eggs, preformed products

- Output ingredients

- packaged chocolate products, packaged hard caramels, packaged jelly products, packaged chocolate balls, packaged chocolate eggs, packaged preformed products

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Transfer type

- Oscillating and moveable product transfer conveyor

- Motor type

- Three-phase motor driven

- Conveyor control

- Frequency controller integrated within the switch cabinet

- Drive system

- Two separate servo motors

- Cleaning access

- Removable conveyor support plates

- Maintenance feature

- Quick tensioning devices for the conveyor belts

- Product transfers

- Pneumatic web tracking control

- Waste management

- Sliding waste trays underneath

- Return shaft diameter

- 10 mm

- Optional stage

- Additional reversible conveyor stage

- Working mechanism

- Oscillating and moveable product transfer conveyor

- Integrated steps

- Transfer of entire product mould configuration

- Automation level

- Three-phase motor driven with frequency controller

- Cleaning method

- Easy access with removable support plates

- Conveyor adjustment

- Quick tensioning devices

- Conveyor reversibility

- Optional reversible conveyor stage

- Product Configuration

- Mould configuration

- Product Type

- Chocolate, Hard Caramels, Jelly

- Shape and Form

- Preformed, individual rows or blocks

- Handling Type

- Bulk product transfer

- Conveyor mechanism

- Oscillating and moveable product transfer conveyor

- Motor type

- Three-phase motor driven

- Pneumatic control

- Pneumatic web tracking control

- Cleaning access

- Easy access for cleaning through removable conveyor support plates

- Main material

- Stainless steel (implied)

- Tilting mechanism

- Driven by two separate servo motors

- Product transfer method

- Pull back function places products on the cross transfer conveyor

- Maintenance accessibility

- Quick tensioning devices for conveyor belts

- Waste management

- Sliding waste trays beneath scrapers

- Reversible conveyor option

- Optional additional conveyor stage

- Control panel type

- Integrated frequency controller

- Conveyor type

- Oscillating and moveable

- Motor type

- Three-phase motor

- Cleaning access

- Removable conveyor support plates

- Maintenance feature

- Quick tensioning devices

- Pneumatic control

- Pneumatic web tracking control

- Servo motor-driven function

- Tilting function

- Reversible stage

- Optional additional reversible conveyor stage