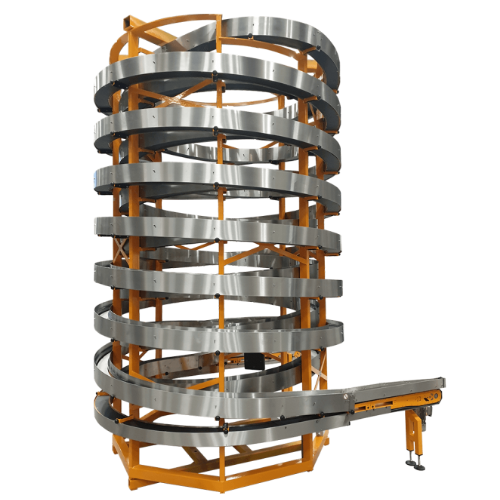

Compact accumulation conveyor for liquid containers

Optimize your space with an ultra-compact conveyor that ensures seamless accumulation and time delay, enhancing production flow for a variety of bottled and packaged products.

Optimizes Product Accumulation and Conveying

The AccuVeyor AVs-Series from AmbaFlex is a space-saving solution designed to streamline accumulation and conveying processes across multiple industries, including logistics, packaging, and bottling. Its ultra-compact spiral design can seamlessly handle a variety of products such as PET water bottles, glass juice bottles, and blister packs, ensuring efficient product flow and time delay management within high-speed, continuous operations. Built with a patented single-belt spiral system, it can manage loads up to 50 kg/m while operating at speeds up to 60 m/min, making it ideal for handling primary packed products and liquid containers in single file. The robust construction allows for medium pressure accumulation with a smooth belt surface, minimizing friction and preventing product damage. Available in different materials for various environments, such as dry use and wash-down setups, the system’s compact footprint—51 m/m² of conveyor per square meter—enables optimal space utilization. Additionally, the AccuVeyor AVs-Series supports easy integration into production lines and can be customized to meet specific operational requirements, ensuring tailored solutions for your production challenges.

Benefits

- Maximizes space efficiency with 51 m/m² conveyor capacity, ideal for limited spaces.

- Enhances product handling with smooth belt surface, preventing damage in high-speed operations.

- Reduces operational costs with maintenance-friendly design suitable for dry and wash-down use.

- Customizable configurations to meet specific industry needs, enhancing integration capabilities.

- Supports diverse product types, from liquid containers to solid packaging, ensuring versatile application.

- Applications

- Personal care products, Bottled beverages, Cartons, Liquid containers, Candy bars, Primary packaging, Pharmaceuticals

- End products

- Liquid soap dispensers, Pill bottles, Glass juice bottles, Toothpaste tubes, Energy bars, Milk cartons, Pet water bottles, Blister packs, Chocolate bars, Shampoo bottles, Drink cartons

- Steps before

- Filling, Primary packaging

- Steps after

- Secondary packaging, Labeling, Palletizing

- Input ingredients

- bottles, glass containers, PET containers, primary packed products, liquid containers, personal care items, pharmaceutical products, cartons, candy bars

- Output ingredients

- bottles, glass containers, PET containers, packaged products, accumulated goods

- Market info

- AmbaFlex is renowned for its expertise in manufacturing innovative spiral conveyor solutions, specializing in dynamic material handling systems across various industries, enhancing efficiency and operational flow with customizable, space-saving designs.

- Conveyor Length per Footprint

- 51 m/m² (15.5 ft/ft²)

- Belt Width

- 100 - 140 mm | 4-5.5”

- Load Range

- up to 50 kg/m | 34 lb/ft

- Speed Range

- up to 60 m/min | 200 fpm

- Belt Length per Drive

- 120 m | 400 ft

- Outer Diameter

- 100 mm to 2440 mm

- Footprint Dimension

- various, e.g., 1751 x 1500 mm

- Material Compatibility

- Dry use, Wipe down, Wash down (CR/RS)

- Working mechanism

- SpiralVeyor SVs with one belt

- Integrated steps

- Time delay or medium pressure accumulation

- Automation level

- Basic control

- Batch vs. continuous operation

- Continuous

- Changeover time

- Minimal due to simplicity

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 1751 x 1500 mm

- Machine footprint

- 2500 x 2500 mm

- Outer diameter

- 1440 mm

- Outer diameter

- 2010 mm

- Belt width

- 100 - 140 mm

- Belt length

- 120 m

- Belt width

- 100 - 140 mm

- Outer diameter

- 100 mm - 2440 mm

- Footprint

- 1751 x 1500 mm - 2500 x 2500 mm

- Load range

- up to 50 kg/m

- Speed range

- up to 60 m/min

- Belt length

- commonly per drive system 120 m