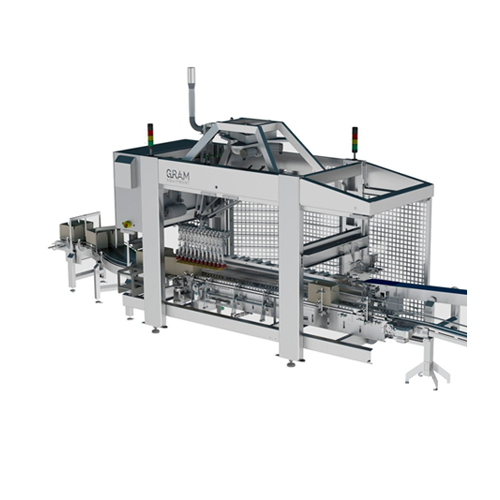

Continuous multi-lane wrapping solution

Achieve precision and speed in packaging with an advanced solution designed for continuous, high-speed wrapping of snacks and confectioneries, ensuring consistent quality and efficiency across multi-lane operations.

Wraps and Seals Multi-Lane Food Products

The GMW Continuous Multi-Lane Flow Wrapper by Gram Equipment is engineered for high-speed, efficient wrapping of solid food products like chocolate bars, protein bars, and wrapped candies. Designed for food processing and confectionery manufacturers, this equipment operates with continuous motion, capable of achieving up to 80 strokes per minute. Its modular build allows for easy replacements and format change-overs, accommodating a wide range of product sizes and types with both hot and cold sealing options. The ProCut knife system ensures precise cuts, enhancing operation reliability by preventing unintentional knife damage. This flow wrapper seamlessly integrates into your packaging line, supported by back-up systems to maintain performance until scheduled maintenance. With TPM readiness and easy module adjustments, the GMW provides robust performance and flexibility for modern packaging solutions.

Benefits

- Enhances production efficiency with continuous high-speed operation.

- Minimizes downtime through modular design and quick change-overs.

- Protects cutting components with the advanced ProCut knife system.

- Ensures consistent package quality with versatile hot and cold sealing.

- Maintains uninterrupted performance with critical backup systems.

- Applications

- Sweets, Confectionery, Food products, Snacks

- End products

- Granola bars, Wrapped candies, Wrapped biscuits, Wrapped cookies, Chocolate bars, Individual portion snacks, Chewing gum, Protein bars

- Steps before

- Ingredient preparation, Product forming, Mixing, Cooling

- Steps after

- Packing, Sealing, Labeling, Quality control

- Input ingredients

- Output ingredients

- Market info

- Gram Equipment is known for manufacturing innovative industrial ETO equipment for the ice cream industry, offering advanced technology solutions and a strong reputation for high-quality, reliable machinery tailored to customer needs.

- Capacity

- Up to 80 stroke/min

- Efficiency

- High efficiency ProCut knife system

- Flexibility

- Very wide product range and format change-over

- Reliability

- Back-up systems of critical parts

- Automation

- TPM ready

- Seal options

- Hot and cold seal

- Build type

- Modular build up

- Working Mechanism

- Flow wrapping

- Automation level

- PLC-controlled

- Modular Build

- Easy replacement of modules

- Capacity

- Up to 80 strokes/min

- Flexibility

- Wide product range, easy format change-over

- Reliability

- Back-up systems for critical parts

- Changeover Time

- Quick and easy

- Seal Type

- Hot and cold seal

- TPM Readiness

- Yes

- Knife System

- ProCut high-efficiency system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Applicable

- Product range

- Wide

- Changeover ease

- Easy format change-over

- Machine Capacity

- up to 80 strokes/min

- Flow Wrapper Type

- Continuous Multi-Lane

- ProCut Knife System

- High efficiency, protects knives

- Format Change-over

- Easily done

- Module Replacement

- Easy replacement

- Sealing Type

- Hot and cold seal

- Control panel type

- TPM ready

- Integration possibilities

- Easy module replacement

- Seal type

- Hot and cold seal

- Product range

- Very wide