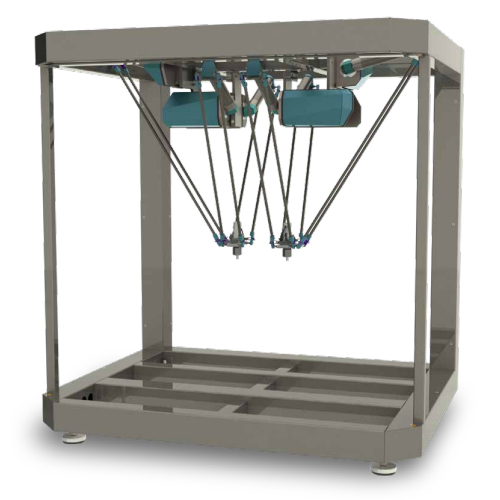

Direct drive delta robots for precision handling

Enhance operational speed and precision with innovative direct drive delta robots, designed to streamline complex tasks like sorting and placing while minimizing maintenance.

Picks, Places, Sorts, and Cuts Products

The ABIflexx Delta Robots with Direct Drive Motors from ABI are engineered to meet the demands of high-speed manufacturing lines requiring precision and hygiene. These delta robots are unique due to their direct drive motors, which eliminate the need for traditional gear mechanisms, resulting in quieter, maintenance-free operation. Ideal for applications ranging from food and pharmaceuticals to semiconductor and automotive components, they efficiently pick, place, sort, and cut solid products such as snack packs, vials, and microchips. The modular design allows for seamless integration into existing production lines, enhancing automation with consistent accuracy and speed. Energy efficiency is a standout feature, with the direct drive technology reducing energy consumption by removing gear-related losses. Constructed with hygienic materials, the robots are optimal for environments where contamination control is paramount. The absence of oil-filled gearboxes simplifies cleaning, significantly reducing downtime. ABI offers comprehensive engineering support for customization to fit specific operational needs, ensuring the ABIflexx Delta Robots enhance productivity while maintaining industry compliance.

Benefits

- Improves operational efficiency with maintenance-free, direct drive technology.

- Enhances product handling speed and accuracy, boosting production rates.

- Minimizes energy costs by eliminating gear-related power losses.

- Ensures compliance with hygiene standards, critical for food and pharmaceutical sectors.

- Facilitates seamless line integration with modular design and engineering support.

- Applications

- Hygiene-sensitive products, Unpackaged products, Graphic industry components, Semiconductor components, Packaging industry items, Packaged products, Multi-axis handling systems, Vehicle technology components, Food products, Automation of manufacturing lines, Horticulture products, Pharmaceuticals

- End products

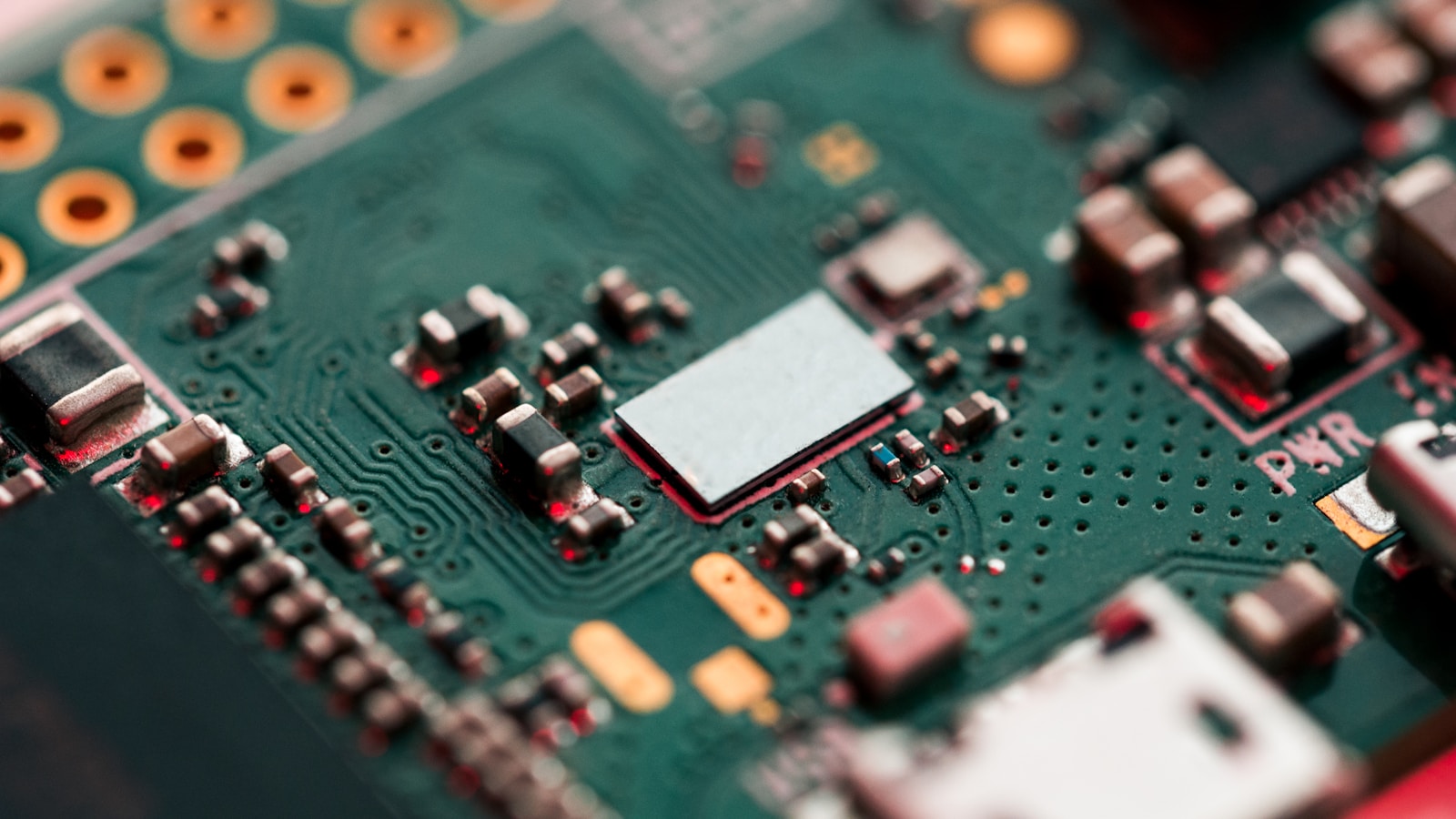

- Flower bulbs, Plant seedlings, Circuit boards, Conveyors, Snack packs, Automotive sensors, Vials, Sliced bread, Blister packs, Microchips, Chocolate bars, Cartridges, Mechanical arms

- Steps before

- Product preparation, Component alignment, Material feeding, Load positioning

- Steps after

- Sorting, Packing, Quality inspection, Distribution

- Input ingredients

- packaged products, unpackaged products

- Output ingredients

- sorted products, processed products, cut food

- Market info

- Motor Type

- Direct Drive

- Speed

- High speed

- Accuracy

- High precision

- Noise Level

- Low noise

- Maintenance

- Low maintenance

- Hygienic Design

- Suitable for hygiene-sensitive processes

- Gripper Rotation

- Available with direct drive motor

- Working Mechanism

- Delta robot configuration

- Drive Type

- Direct drive motors

- No. of Axes

- 3–4 axes

- Accuracy

- High precision

- Speed

- Fast

- Noise Level

- Low noise

- Maintenance Requirement

- Maintenance-free

- Automation level

- PLC-controlled

- Hygienic Design

- Suitable for food industry

- Application flexibility

- Gripper rotation add-on

- Suitable for

- Food packaging, sorting, etc.

- Machine footprint

- Compact

- Robot configuration

- Delta

- Drive type

- Direct drive

- Modular design

- Yes

- Space-saving

- Up to 50% reduction

- Noise level

- Low

- Hygienic design

- Yes

- Discharge method

- Gripper with rotation

- Modular design

- Yes

- Gripper rotation

- Direct drive motor, fully integrated

- Control panel type

- KEBA controllers

- Integration possibilities

- Robot integration with ABIflexx Robotic Systems