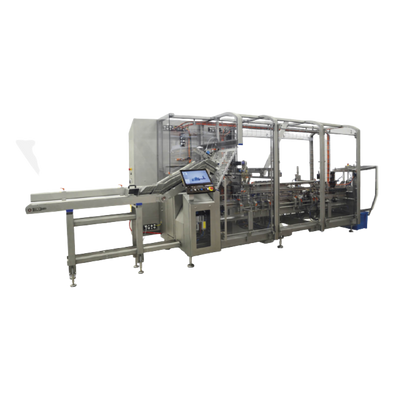

Cartoning Machine For Snacks and Sweets

When producing different snacks and sweets, each product will match a different carton size in packaging. A flexible cartoning system that can quickly switch from one packaging size to another maximizes production capacity while reducing the footprint of the working area.

Pack all cartons with a smart horizontal cartoning system

The VENTO Cartoner, from Mpac, is a hygienic food cartoning system often set up for customers who pack chocolate bars, energy bars, sweets, and other snacks. The unit is equipped with an advanced intelligent machine interface that provides information on machine status, predictive maintenance, and quick changeover procedures for better flexibility. It is made of hygienic stainless steel materials with an accessible design for easy cleaning. The system is servo-driven and coupled directly to its components for reliable operation and minimum wear over time. Its open design allows an optimal view of the machine’s operation and product flow. Packaging processes include carton erecting, loading, transportation, and closing.

Benefits

- Changeover procedures of about 10 minutes

- Max output: 500 cartons/ min

- Wide range of carton sizes, types, custom formats

- Hygienic design

- Long operating life, minimal wear