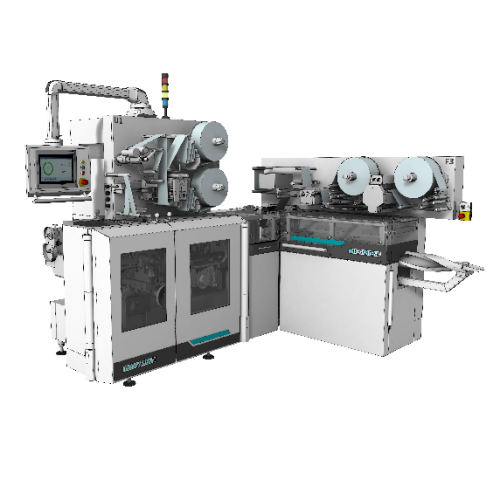

High speed fold wrap and stick packs packaging system

Enhance your confectionery production line with a packaging system that efficiently integrates cutting, folding, and wrapping into one high-speed, continuous operation, ensuring precise packaging for diverse solid products such as sweets, chocolates, and tablets.

Forms, Cuts, and Wraps Confectionery Products

The U1-DCW+F3 from Theegarten-Pactec is an engineered-to-order high-speed packaging system designed specifically for the food and confectionery industries. It combines a versatile primary packaging machine with a secondary fold wrap system to address the packaging needs of diverse solid products, including soft caramels, toffees, chewing gums, and more. By utilizing a twin-lane execution, it processes up to 2,000 individual items per minute and creates 300 folded stick packs per minute, enhancing efficiency and output. The equipment supports various folding styles, such as bottom, side, and envelope folds, ensuring flexibility in the packaging operation. Its compact design facilitates seamless integration into existing production lines while minimizing its footprint. This system’s advanced automation capabilities, including PLC control for remote operation, improve operational efficiency and monitoring. Constructed from robust materials, it ensures durability and low maintenance, offering custom configurations to align with specific production requirements.

Benefits

- Maximizes operational capacity with dual-lane processing, enabling high-speed packaging of up to 2,000 items per minute.

- Reduces production floor space needed with its compact design, allowing easy integration into existing lines.

- Enhances flexibility with multiple wrapping options to cater to various product needs.

- Decreases labor involvement and increases precision through advanced PLC control and automation.

- Minimizes material waste while maintaining packaging effectiveness, contributing to reduced production costs.

- Applications

- Chewy sweets, Soft caramels, Bouillon cubes, Hard candies, Chocolates, Eclairs, Toffees, Bubble gum, Cereals, Jelly products, Effervescent tablets, Dishwasher tablets, Preformed products, Krówki, Chewing gum

- End products

- Mint flavored chewing gum, Herb-infused bouillon cubes, Gummy bears, Classic chocolate eclairs, Polish krówki candies, Soft butter caramels, Strawberry bubble gum, Molded chocolate truffles, Fruit chewy candies, Orange flavored effervescent tablets, Lemon-scented dishwasher tablets, Milk chocolate bars, Lemon hard candies, Honey nut granola clusters, English toffees

- Steps before

- Product Feeding, Material Preparation

- Steps after

- Final Packaging, Distribution, Storage

- Input ingredients

- soft caramels, toffees, chewy sweets, chewing gum

- Output ingredients

- wrapped individual products, stick packs, fold wrap, bottom fold, side fold, envelope fold

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Speed

- Up to 2, 000 wrapped products per minute

- Capacity

- Up to 300 stick packs per minute

- Wrapping Styles

- Bottom fold, Side fold, Envelope fold

- Output Rate

- 1, 800 single products/min, 300 stick packs/min

- Twin lane execution

- Yes

- Primary Packaging

- Fold wrap

- Secondary Packaging

- Folded stick packs

- Compact Design

- Small footprint

- Automation level

- PLC

- Batch vs. continuous operation

- Batch

- Changeover time

- Quick change

- Cleaning method

- Manual

- CIP/SIP

- N/A

- Energy efficiency

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Soft Texture Handling

- Gentle Control

- Candy Versatility

- Multi-shape

- Machine footprint

- Compact design for small footprint

- Discharge method

- Double lane cutting, folding and sealing units

- Compact footprint

- Compact design for small footprint