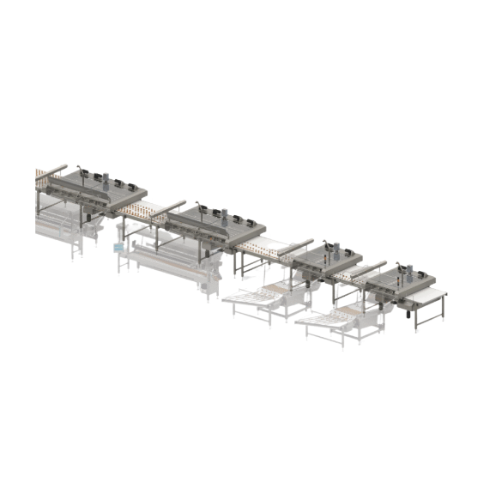

High-volume product distribution system

Efficiently manage high-volume snack and confectionery production flows with a system designed to distribute products seamlessly across multiple packaging lines, ensuring optimal handling and precision loading to maintain product integrity.

Distributes and Manages High-Volume Product Flow

The Flowmaster from Royal Houdijk revolutionizes product distribution in the food packaging industry by efficiently managing high-volume flows. This system adeptly distributes diverse products such as potato chips, candy bars, and snack packs across multiple downstream packaging legs like slug wrappers and tray loaders. Its operation is seamless, utilizing a flat product handling technique that preserves product integrity by preventing squeezing or scuffing. Capable of continuous, high-speed operations, the Flowmaster integrates easily into existing production lines and meets the dynamic needs of confectionery and snack manufacturers. With its flexible design and capacity for high throughput, it’s ideal for food producers looking to optimize their packaging efficiency. Available in materials suitable for food contact, it is constructed to endure the rigorous demands of packaging environments while simplifying maintenance through its accessible design.

Benefits

- Enhances packaging efficiency by evenly distributing high-volume product flows across multiple packaging lines.

- Preserves product quality by preventing damage with flat product handling.

- Integrates seamlessly with existing systems, offering flexibility to accommodate various packaging types.

- Optimizes operation with continuous and high-speed processing capabilities.

- Reduces maintenance time and costs with a design that simplifies access and cleaning.

- Applications

- Slug wrappers, Snacks, Sweets, Tray loaders, Vending packs, Portion packs

- End products

- Individually wrapped candies, Granola bars, Snack packs, Cookie packs, Potato chips, Candy bars, Chocolate bars, Muesli snack packs, Nut mix portions, Biscuit packs, Dried fruit packs

- Steps before

- Product Sorting, Product Inspection, Conveyor Loading

- Steps after

- Packing, Portion Packaging, Tray Loading, Slug Wrapping, Vending Pack Wrapping

- Input ingredients

- random incoming product flow, high volumes of product

- Output ingredients

- distributed product flow, multi-leg downstream equipment

- Market info

- Houdijk is known for designing and manufacturing advanced handling and processing equipment for the biscuit and bakery industry, specializing in automated systems to improve efficiency and maintain product quality.

- Product Handling

- Flat on belt

- Product Distribution

- Random incoming flow

- Capacity

- High volume lines

- Automation

- On demand distribution

- Flexibility

- Multi-leg distribution

- Handling Surface

- Stable bottom surface

- Product distribution method

- Random to multi-leg wrappers

- Handling method

- Flat on belt

- Flexibility

- Accommodates various loading systems

- Product stability

- Prevents squeezing or scuffing

- Automation level

- Automatic

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Distribution flexibility

- Multi-leg downstream equipment

- Machine footprint

- Compact/Flexible

- Product handling orientation

- Flat on belt

- Discharge method

- Multi-leg distribution

- Surface handling

- Stable bottom surface

- Control panel type

- Touchscreen / Push-button

- Integration possibilities

- PLC / SCADA / MES

- Product distribution flexibility

- Custom distribution percentages