Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection technology designed to detect contaminants and verify weights, enhancing manufacturing integrity and consumer trust.

Detects Contaminants and Ensures Accurate Weights

Our Checkweighers, X-Ray Inspection, and Metal Detection Systems are engineered by Viking Masek to address the critical needs of high-speed, continuous operations in diverse industries such as food, beverage, and medical sectors. These systems are designed to detect foreign contaminants and ensure accurate package weights, minimizing the risk of recalls and enhancing product integrity.

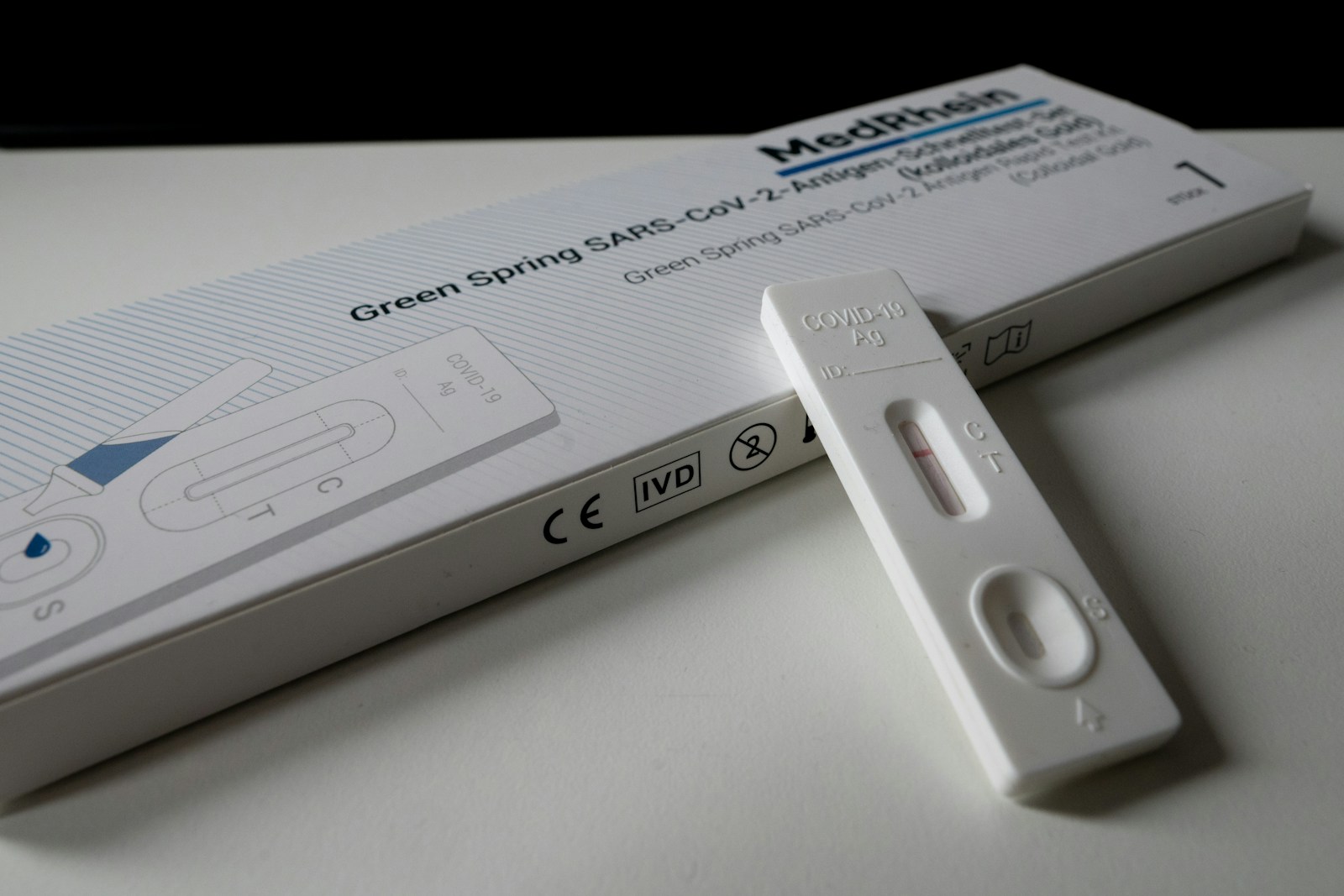

The equipment operates by integrating precision weighing mechanisms with advanced X-ray and sensory technology to inspect products thoroughly. Suitable for applications ranging from solid foods to powders and liquids, these systems support the production of end-products like espresso coffee beans, orange juice, and pregnancy test kits.

Boasting a high throughput capacity, our solutions are tailored for seamless integration into existing production lines with automation capabilities that allow for remote monitoring. Designed with energy efficiency in mind, the equipment reduces operational costs by utilizing optimized motor controls. Fabricated from durable materials, they comply with industry standards such as GMP and FDA, ensuring the highest level of safety and sanitary operation.

Easy to maintain, these systems feature user-friendly interfaces and CIP (Clean-In-Place) capabilities for efficient, contamination-free internal cleaning. Additionally, Viking Masek provides comprehensive engineering support, facilitating customization options that include specific size configurations and enhanced detection features to meet unique production requirements.

Benefits

- Enhances product safety and quality assurance by detecting contaminants before distribution.

- Minimizes the risk of recalls through precise weight verification.

- Integrates seamlessly into production lines, optimizing operational efficiency and reducing setup time.

- Lowers operational costs with energy-efficient sensors and motor controls.

- Ensures compliance with industry standards such as GMP and FDA, facilitating market access.

- Applications

- Treats, Medical devices, Snacks, Bakery, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Candy, Pasta, Pet food, Individual quick frozen (iqf), Nuts, Natural, Rice, Cereal, Beverage, Meat, Coffee, Vegetables, Poultry, Powders

- End products

- Spaghetti, Espresso coffee beans, Bottled water, Dog kibble, Lentils, Instant powdered milk, Potato chips, Cashew nuts, Baby carrots, Riced cauliflower, Basmati rice, Almond butter, Whey protein powder, Laundry detergent, Chicken breast, Orange juice, Blood glucose test strips, Canned tuna, Organic quinoa, Cold brew coffee, Croissants, Frozen berries, Bandages, Cheddar cheese, Ibuprofen tablets, Cornflakes, Granola, Cat treats, Cannabis oil, Pregnancy test kits, Vitamin c capsules, Chocolate bars, Muesli

- Steps before

- Steps after

- Packing, Product Inspection, Contamination Risk Minimization, Consumer Confidence Increase, Weight Accuracy Ensuring

- Input ingredients

- food products, beverages, coffee, cannabis, IQF products, powders, cereal, nuts, snacks, fresh fruit, vegetables, liquids, meat, poultry, fish, pet food, treats, candy, pasta, beans, rice, organic foods, cheese, bakery products, pills, capsules, medical devices, medical testing kits, non-food products

- Output ingredients

- inspected packages, contamination-free products, accurate weight packages, safe packages

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Accuracy

- ±0.1 g to ±5 g

- Detection type

- X-ray / metal detection

- Capacity

- Flexible to application needs

- Automation

- PLC-controlled

- Contamination risk reduction

- High

- Product handling

- Automatic rejection

- Working mechanism

- Checkweighers, X-Rays, Metal Detection

- Integrated steps

- Product inspection for accuracy and safety

- Automation level

- Integration with other packaging systems

- Batch vs. continuous operation

- Continuous for inline operations

- Cleaning method

- CIP / Manual

- Changeover time

- Fast, optimized for minimal downtime

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes/No

- Control panel type

- Digital / Analog

- Discharge method

- Automatic / Manual

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- SCADA / ERP systems

- Footprint

- Compact / Modular

- Modularity

- Expandable / Flexible