Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper that delivers consistent sealing and wrapping for a diverse range of products, from chocolates to medical devices, ensuring efficiency and product integrity at every turn.

Packs, Seals, and Wraps Varied Products Efficiently

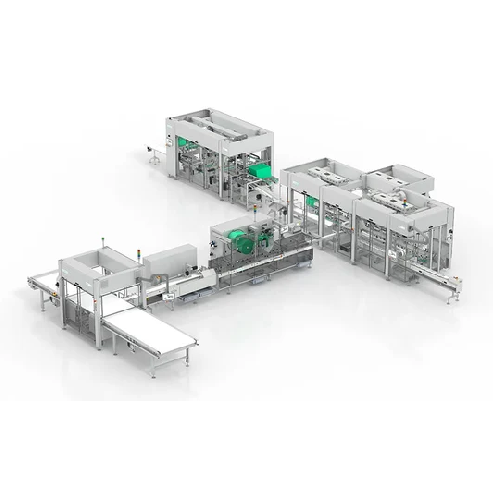

The Pack 102, Pack 403, and Sigpack HML from Syntegon are versatile horizontal flow wrappers that revolutionize packaging across multiple industries. These machines efficiently pack, seal, and wrap products like chocolate, croissants, detergent pods, and blister packs through seamless integration into your production line. With an automatic, high-speed operation capable of processing both entry-level and complex applications, these systems handle a diverse range of materials including solids, powders, and frozen goods.

The flow wrappers incorporate a horizontal form-fill-seal process, ensuring tight, reliable seals through heat, cold, or ultrasonic technologies. Syntegon’s equipment boasts throughput capacities from startup-friendly speeds to high-output levels of up to 1,500 packages per minute. They facilitate eco-friendly transitions with options for recyclable mono-materials and paper-based solutions.

Designed for easy integration, they offer synchronized system operations with a uniform control platform for enhanced product flow. Syntegon provides customization and engineering support, allowing tailored solutions to meet specific packaging requirements, ensuring optimal operational efficiency, and supporting your production goals. These wrappers meet stringent hygiene standards, with easy-to-clean components, making them suitable for food and pharmaceutical production environments.

Benefits

- Enhances operational efficiency with high-speed capabilities up to 1,500 packages per minute.

- Reduces environmental impact with sustainable packaging options like recyclable mono-materials.

- Minimizes product damage through advanced feeding and distribution systems.

- Ensures seamless production integration with a uniform control platform across systems.

- Lowers maintenance effort with easy-to-clean, hygienic designs suitable for sensitive applications.

- Applications

- Cookies, Biscuits, Frozen food, Medical devices, Detergents, Snacks, Pet food, Confectionery, Coffee, Solid goods, Bakery goods, Bars, Pharmaceutical products, Chocolate, Tea

- End products

- Oatmeal cookies, Tea bags, Pralines, Frozen vegetables, Kibble, Dark chocolate bars, Insulin pens, Potato chips, Butter biscuits, Croissants, Laundry detergent tablets, Detergent pods, Instant coffee sachets, Blister packs for tablets, Protein bars

- Steps before

- Product distribution, Feeding systems, Product preparation

- Steps after

- Secondary packaging, Case packing, System integration

- Input ingredients

- single roll of film, variety of products, chocolate, biscuits, baked goods, bars, frozen food, solid goods, detergent tabs, pharmaceutical products, BFS cards, tablets in blisters

- Output ingredients

- horizontal bag, sealed pouches, packaged products, sealed flow wraps, hermetically sealed packs, multi packs, packaging for variable shapes and textures, sealed vials, pens, or inhalers

- Market info

- Syntegon is known for its expertise in processing and packaging technology, offering innovative solutions for the food and pharmaceutical industries. It has a strong reputation for advanced equipment, sustainability, and customer-oriented service.

- Maximum production speed

- Up to 1, 500 packages/min

- Minimum production speed

- 80 packages/min

- Entry-level speed

- Up to 150 packages/min

- Sealing method

- Heat or ultrasonic technology

- Automation level

- Fully automated

- Pack format flexibility

- On edge / stacked

- Sealing competence

- High-quality sealing

- Material types

- Recyclable mono-materials / paper-based

- Control platform

- Uniform control platform

- HMI features

- Real-time information and maintenance instructions

- Output rate for HML

- 200 to 250 packages/min

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Rapid changeovers

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- Easy and quick disassembly

- Recyclable mono-materials

- Yes

- Paper-based packaging

- Yes

- Bio-based materials

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Yes

- Product size

- Various

- Shape variability

- Yes

- Type of product

- Food, pharmaceutical

- Product composition

- Solid, Liquid

- Packaging format

- Customizable

- Machine footprint

- Compact

- Control panel type

- New HMI

- Discharge method

- Horizontal

- Frame construction

- Robust

- Modular design

- Yes

- Control panel type

- HMI with real-time information

- Integration possibilities

- System integration with uniform control platform

- Modular design

- Configurable modular bakery systems

- Material compatibility

- Supports paper and mono-materials

- Sealing technology options

- Heat, ultrasonic, and cold sealing

- Automation level

- From entry-level to fully automated systems

- Packaging format flexibility

- On edge or stacked, multi packs

- Product arrangement

- Customizable for various product types

- Output capacity variations

- 80 to 1, 500 packages per minute

- Film type compatibility

- Paper and recyclable mono-materials

- Material switching options

- Retrofit kit for paper-ON-form

- Feeding and distribution systems

- Advanced feeding integration

- Cleaning accessibility

- Easy cleaning and hygienic design