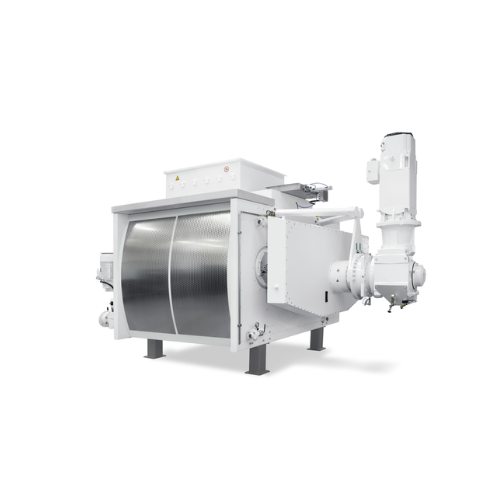

Double-overthrow conche for chocolate production

Achieve precise taste and texture in chocolate production with reduced energy costs and footprint, all while maintaining outstanding hygiene standards and ensuring fast, efficient conching.

Refines and Modifies Chocolate Texture and Flavor

The Frisse DÜC S Double-Overthrow Conche from Bühler Group revolutionizes chocolate processing with its sophisticated conching technology. It employs a dual overthrow mechanism to enhance shearing and kneading, ensuring rapid texture development and flavor maturation. Specially tailored for chocolate and confectionery producers, it manages a variety of applications including chocolate bars, truffles, and coatings. The conche’s direct-drive system optimizes energy consumption, reducing costs by up to 10% compared to traditional systems, and integrates seamlessly into high-speed, automated production lines with Profinet and Ethernet connections. It offers precise temperature control for assured product consistency, and the reduced machine footprint saves valuable factory space. Constructed with food-grade materials, it meets stringent hygiene standards and includes improved maintenance access, facilitating quick servicing and minimizing downtime. Customize your conching solution with Bühler’s global engineering expertise to enhance efficiency and plant performance.

Benefits

- Enhances product quality with precise rheological adjustments and efficient volatile removal.

- Lowers operational costs with a direct-drive system, reducing energy consumption by up to 10%.

- Increases productivity with improved machine availability and reduced maintenance time.

- Optimizes factory space with a compact design and reduced machine footprint.

- Ensures compliance with high hygiene standards using food-grade materials.

- Applications

- Snacks, Compounds, Confectionery, Sweets, Chocolate mass

- End products

- Chocolate truffles, Filled chocolates, Chewy sweets, Confectionery coatings, Candy bars, Chocolate bars, Cocoa butter-based compounds, Chocolate chips, Chocolate spreads, Chocolate snacks

- Steps before

- Grinding, Mixing, Blending, Emulsification

- Steps after

- Cooling, Tempering, Packing, Moulding, Sorting

- Input ingredients

- cocoa, chocolate mass, compounds

- Output ingredients

- liquid chocolate, chocolate mass, compounds, bars

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Energy Efficiency

- Saves up to 10% in energy costs

- Automation

- Profinet and Ethernet connectivity

- Footprint

- Reduced footprint for factory space efficiency

- Temperature Control

- Compact rack with ConcheOS software

- Shear Force Application

- High application for short conching times

- Drive System

- Direct drive with variable frequency

- Service Access

- Improved access to product room seals

- Working mechanism

- Double-overthrow conche

- Automation level

- PLC / SCADA with Profinet and Ethernet

- Batch vs. continuous operation

- Inline continuous

- Energy efficiency

- 10% energy savings with direct drive

- Changeover time

- Faster service with improved access to parts

- CIP/SIP

- Meets highest hygiene standards

- Cleaning method

- CIP

- Precise temperature control

- ConcheOS software controlled

- Integrated steps

- Rheology adjustment and volatile removal

- Cleanability

- Hygienic design, food-grade materials

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Yes

- Abrasion resistance

- High due to durable engineering

- Compact footprint

- Reduced footprint

- Discharge method

- Double-overthrow

- Control panel type

- Profinet and Ethernet connectivity

- Control panel type

- Profinet / Ethernet connectivity

- Integration possibilities

- SmartFactory solutions compatibility

- Customization support

- Yes, tailored solutions based on requirements

- Drive system

- Direct drive with seal exchange system

- Automation level

- Fully automated with ConcheOS software

- Temperature control

- Compact rack with improved serviceability