Tray and lid forming solution for food packaging

For manufacturers needing precision packaging, this machine seamlessly forms and seals trays and lids, optimizing product display while accommodating diverse shapes and sizes.

Forms, Loads, and Glues Trays and Lids

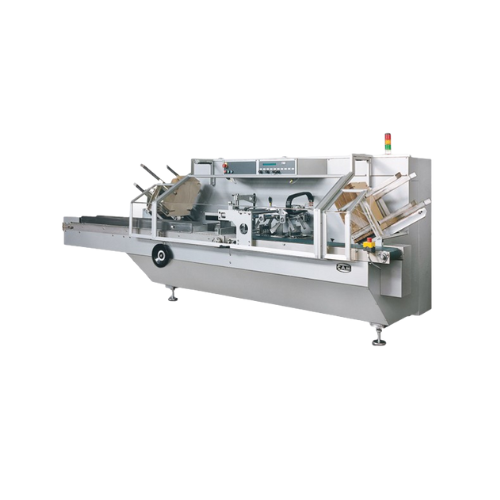

The FCE tray and lid forming machine from CAM offers a seamless solution for packaging lines in the food and confectionery industries. Designed to handle a variety of products including jars, bottles, and bags, the FCE ensures precise loading and gluing with a reliable hot-melt application system. It operates by forming a tray with high or shaped low edges, integrating seamlessly into production lines with its automatic product feeding and collation. The machine handles package sizes ranging from 100 x 25 x 100 mm to 400 x 200 x 320 mm, reaching speeds up to 20 cycles per minute. Its cantilever structure allows for easy maintenance and cleaning, while housing critical components in the rear to separate them from the working area. Customizable feeding systems accommodate products with regular or irregular shapes, providing flexibility for diverse packaging requirements.

Benefits

- Enhances packaging efficiency with high-speed operations of up to 20 cycles per minute.

- Customizable product feeding systems increase flexibility for diverse packaging needs.

- Simplifies maintenance and reduces downtime with an accessible cantilever design.

- Ensures secure packaging with precise hot-melt glue application.

- Offers versatility in handling both standard and non-standard package sizes.

- Applications

- Food, Snacks, Jars, Confectionery, Sweets, Ampoules, Chocolate bars, Granulates, Powders, Bottles

- End products

- Chocolate truffles, Assorted candy boxes, Spice jars, Energy drink bottles, Cooking oil bottles, Fruit jelly jars, Cereal bars, Multi-pack chips, Nutritional supplements bottles, Vitamin ampoules, Protein granulates, Sugar packets, Chocolate-coated nuts, Honey jars, Seasoning powder packs, Coffee granules jars, Flavored granola bags, Protein powder containers

- Steps before

- Product sorting, Blanks loading, Glue preparation, Product arrangement

- Steps after

- Package sealing, Quality inspection, Labeling, Distribution

- Input ingredients

- open blanks, products, regular sizes, sticks, small cartons, jars, bottles, ampoules, irregular shapes, pillow bags, Doypack bags, flat bottom bags, snacks, chocolate bars, corrugated cardboard, compact cardboard, monomaterial pack

- Output ingredients

- formed tray and lid, finished packages, multi packages

- Market info

- CAM Packaging is known for its expertise in designing and manufacturing advanced packaging machinery tailored to client specifications, with a strong reputation for reliability and innovation in the engineered-to-order equipment market.

- Package Size Range

- 100 x 25 x 100 mm to 400 x 200 x 320 mm

- Speed

- Up to 20 cycles per minute

- Automation

- Automatic feeding and collation systems

- Structure Type

- Cantilever structure

- Material Compatibility

- Compact or corrugated cardboard

- Glue Type

- Hot-melt glueing

- Working mechanism

- Tray and lid forming with glue application

- Integrated steps

- Packing, loading, glueing, and assembly

- Operation speed

- Up to 20 cycles per minute

- Handling capability

- Regular and irregular shaped products

- Customization options

- Automatic feeding and collation systems

- Material handling

- Corrugated or compact cardboard

- Batch vs. continuous operation

- Batch

- Cleaning method

- Open structure for easy cleaning

- Machine footprint

- Varies

- Accommodates packages from 100 x 25 x 100 mm to 400 x 200 x 320 mm

- Cantilever structure

- Yes

- For easy operator access and cleaning

- Discharge method

- Hot-melt glueing

- Package dimensions

- 100 x 25 x 100 mm to 400 x 200 x 320 mm

- Cycle speed

- Up to 20 cycles per minute

- Magazine capacity

- Capacious magazines for blanks

- Control panel type

- HMI / PLC

- Integration possibilities

- Customized product feeding and collation systems

- Packaging material

- Compact or corrugated cardboard

- Package size range

- 100 x 25 x 100 mm up to 400 x 200 x 320 mm

- Machine speed

- Up to 20 cycles per minute

- Product type compatibility

- Sticks, small cartons, jars, bottles, ampoules, pillow bags, Doypack bags, flat bottom bags, snacks, chocolate bars