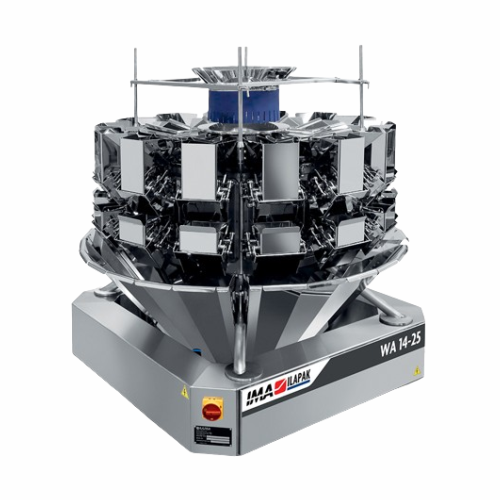

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product categories, from chocolates to frozen goods, ensuring optimal distribution and reduced waste in high-speed production environments.

Weighs and Counts Diverse Food Products

The WA 14-25 from IMA Group is a precision multihead combination weigher that revolutionizes portion control for confectionery, bakery, and snack products. Utilizing high-speed stepper motors and advanced vibratory or rotary distribution systems, it accurately weighs and counts products from chocolate candies to frozen chicken nuggets. With a processing capacity of up to 25 grams per single dump, it operates continuously for high throughput. The WA 14-25 is constructed from hygienic AISI 304 stainless steel with optional special coatings, ensuring durability and cleanliness. Its user-friendly interface supports efficient operation and integration into processing and final conditioning lines. Additionally, its quick-release components facilitate easy maintenance and wash-down cleaning, supporting compliance with stringent food safety standards.

Benefits

- Enhances accuracy, minimizing product giveaway with its high-precision weighing algorithm.

- Simplifies cleaning and maintenance with quick-release, hygienic components.

- Increases operational efficiency by supporting both weighing and counting modes.

- Decreases food waste through precise portioning for diverse product types.

- Integrates seamlessly into existing production lines with flexible configuration options.

- Applications

- Snacks, Confectionery, Bakery, Dry products, Fresh products, Frozen products

- End products

- Bread rolls, Gummy bears, Sliced vegetables, Hard candies, Fresh berries, Sugar cookies, Potato chips, Frozen peas, Mixed nuts, Frozen chicken nuggets, Chocolate candies, Dried fruits, Pretzels

- Steps before

- Product Sorting, Initial Weighing, Product Preparation

- Steps after

- Packing, Sealing, Labeling

- Input ingredients

- dry products, fresh products, frozen products, confectionery, bakery items, snacks

- Output ingredients

- weighed product, counted product

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Max. speed

- 14 weigh heads

- Max. discharge volume (single dump)

- 25 g – 1500 g

- Discharge weight range (single dump)

- 120 mm

- Product distribution

- Vibratory or rotary distribution cone with loadcell

- Product contact parts material

- Stainless steel AISI 304, embossed plate, and special coatings

- Drive

- Springless, high speed stepper motors

- Loadcells

- C3 accuracy class, OIML approved R76 class

- Electronic platform

- Industrial PC

- HMI

- 12” (18” *) colour touch screen with remote control capability

- Program memory

- over 1000 recipes

- Power supply

- 230 Vac±5%, 1 ph, neutral, GND, 50/60 Hz, 1.2 kW, 6 A (3 A @ 480 V)

- Compressed air

- 180 l/min @ 7 bar

- Machine dimensions (W x D x H)

- 1402 x 1402 x 1474 mm (55.2 x 55.2 x 58.03’’)

- Machine weight

- 650 kg

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- PLC / SCADA

- Changeover time

- Quick-release components for easy sanitation and quick maintenance

- CIP/SIP

- Sanitary and wash-down execution

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- 1402 x 1402 x 1474 mm

- Machine weight

- 650 kg

- Hopper volume

- Small, medium, large

- Discharge method

- Vibratory or rotary distribution

- Control panel type

- 12” (18” *) colour touch screen with remote control capability (augmented reality feature*)

- Integration possibilities

- Remote control capability

- HMI type

- User-friendly HMI with easy interface

- Detachable parts

- Easy detachable product contact parts available in plain execution, embossed or special coatings

- Hopper volume options

- Small, medium, and large hopper volume