Metal detector for packaging lines

Ensure product purity and safety with precision metal detection, seamlessly eliminating contaminants and ensuring flawless alignment in high-speed packaging lines.

Detects and Rejects Metal Contaminants

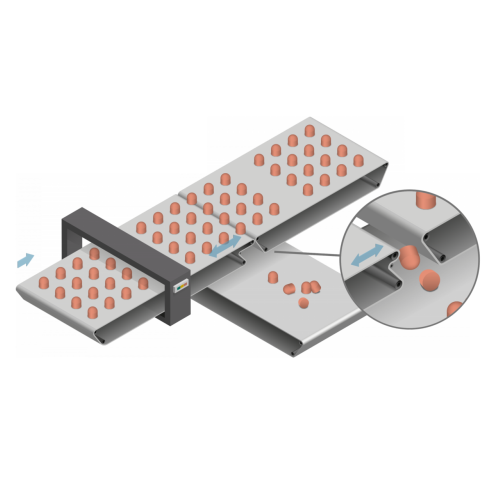

The Metal Detector from Theegarten-Pactec is engineered for food and confectionery producers seeking to maintain high standards of product safety and quality. This equipment specializes in the detection and automatic rejection of metal contaminants in sweets, chocolates, caramels, and other solid products, ensuring compliance with food safety regulations. Its integrated cross reject conveyor efficiently separates contaminated items from properly aligned products, optimizing high-speed packaging lines. The system features a three-phase motor-driven conveyor with frequency control and pneumatic web tracking, allowing seamless integration into continuous operations. Designed for ease of maintenance, the detector includes removable conveyor support plates and quick tensioning devices, while the robust stainless-steel construction ensures durability and corrosion resistance, meeting the rigorous demands of the food industry.

Benefits

- Enhances product safety by efficiently removing metal contaminants.

- Minimizes manual inspection time, increasing overall throughput.

- Integrates seamlessly into existing packaging lines for streamlined operations.

- Facilitates easy maintenance with quick-access components and tensioning devices.

- Durable construction ensures long-term reliability in demanding industrial environments.

- Applications

- Fudge, Hard candies, Caramels, Confectionery, Bouillon cubes, Chocolate products, Toffee, Cereals, Sweets, Jelly products, Effervescent tablets, Dishwasher tablets, Chewing gum

- End products

- Gummy bears, Granola bars, Cornflakes, Lemon effervescent tablets, Chocolate toffees, Peppermint chewing gum, Salted caramels, Vanilla fudge, Dishwasher pod capsules, Chicken bouillon cubes, Rice cereal puffs, Dark chocolate truffles, Milk chocolate bars, Fruit-flavored hard candies

- Steps before

- Processing, Purification, Drying

- Steps after

- Rejection of Contaminated Products, Packing, Distribution, Alignment, Transfer to Packaging Machines

- Input ingredients

- metal contaminated product rows

- Output ingredients

- rejected contaminated products, non-properly aligned products for wrapping

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Detection Type

- Metal

- Rejection System

- Cross Reject Conveyor

- Conveyor Drive

- Three-phase Motor

- Conveyor Control

- Frequency Controller

- Web Tracking Control

- Pneumatic

- Cleaning Access

- Removable Conveyor Support Plates

- Conveyor Maintenance

- Quick Tensioning Devices

- Product Transfer

- Underneath Sliding Waste Trays

- Return Shafts Diameter

- 10 mm

- Product Flow Direction

- Right angles to direction of product flow

- Automation Level

- Three-phase motor driven

- Conveyor Belt Tensioning

- Quick tensioning devices

- Cleaning Access

- Removable conveyor support plates

- Row Alignment

- Optional row aligner

- Product Rejection Method

- Integrated cross reject conveyor

- Compact footprint

- Yes

- Control panel type

- Integrated

- Discharge method

- Cross reject conveyor

- Conveyor type

- Three-phase motor-driven

- Conveyor belt tensioning

- Quick tensioning devices

- Sliding waste trays

- Underneath product transfer

- Metal Detection System

- Integrated cross reject conveyor

- Conveyor Alignment

- Optional row aligner

- Motor Type

- Three-phase motor driven conveyor

- Pneumatic Control

- Pneumatic web tracking control

- Maintenance Ease

- Quick tensioning devices for conveyor belts

- Cleaning Access

- Easy access through removable conveyor support plates

- Product Transfer Mechanism

- Return shafts with diameter 10 mm