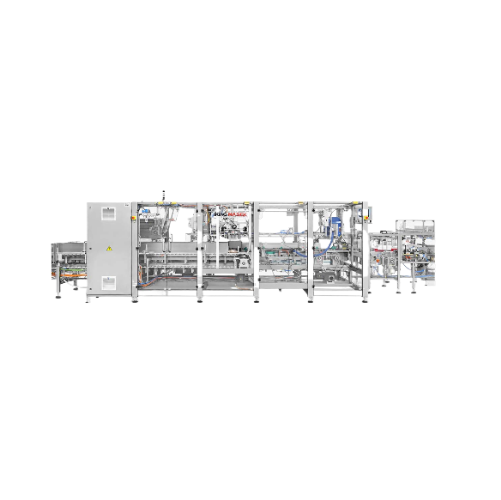

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for efficiently handling a wide range of product sizes and types while maintaining consistency through servo-driven, continuous, or intermittent operations.

Packages Products with Precision and Flexibility

The Endload Cartoner CAM from Viking Masek is a fully servo-driven cartoning solution tailored for industries spanning from food and beverage to medical manufacturing. This versatile machine excels in both continuous and intermittent motion, ensuring seamless integration into varied production environments. It efficiently packages a wide array of products, such as coffee pods, protein powder packets, and medical devices, thanks to its flexible carton size adjustments and servo-driven precision. With a throughput of up to 220 cartons per minute, it is designed for high-efficiency output, whether you are working with solid, liquid, or powder product types. The robust stainless steel construction and user-friendly design simplify maintenance and allow for effortless changeovers, making it an essential component for streamlined and reliable production lines. Options for enhanced customization include remote diagnostics, various closure systems, and extended carton magazine capacity.

Benefits

- Enhances packaging efficiency with variable speed adjustments for diverse products.

- Streamlines production with quick format changeovers, minimizing downtime.

- Ensures product integrity through precise servo-driven motion control.

- Facilitates easy maintenance with ergonomic design and accessible components.

- Adapts to specific requirements with customizable closure systems and diagnostics options.

- Applications

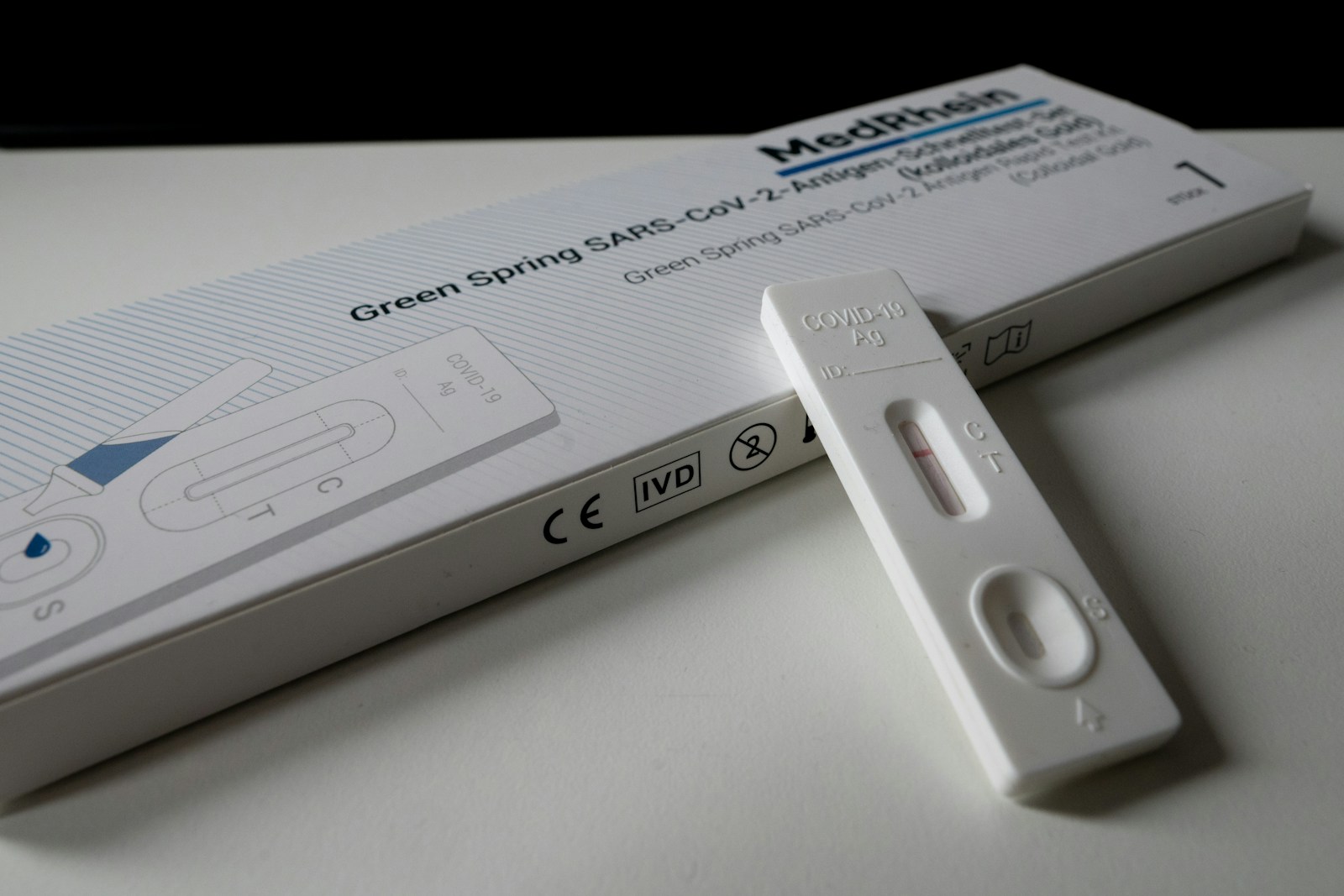

- Treats, Medical devices, Snacks, Bakery, Cheese, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Candy, Pasta, Pet food, Natural, Powder, Rice, Health, Beverage, Meat, Coffee, Medical, Vegetables, Poultry, Organic foods

- End products

- Canned beans, Vitamin pills, Dog kibble, Bottled water, Cheddar blocks, Protein powder packets, Potato chips, Packaged carrots, Spaghetti packages, Organic quinoa packs, Insulin syringes, Salmon fillets, Granola bars, Croissants, Marinated chicken packages, Herbal capsules, Coffee pods, Juice cartons, Rice bags, Surgical masks, Cat treats, Covid-19 testing kits, Sliced apples, Cannabis oil vials, Chocolate bars, Stationery sets

- Steps before

- Product sorting, Feeding

- Steps after

- Case packing, Carton sealing, Palletizing

- Input ingredients

- carton blanks, products for cartoning, packaging materials

- Output ingredients

- endload cartons, packaged products, cartoned items

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Max Speed - Intermittent

- 60 cpm

- Max Speed - Continuous

- 220 cpm

- Carton Size (Intermittent) Min

- 50 mm x 80 mm x 30 mm

- Carton Size (Intermittent) Max

- 400 x 600 x 300 mm

- Carton Size (Continuous) Min

- 50 mm x 80 mm x 20 mm

- Carton Size (Continuous) Max

- 225 x 300 x 100 mm

- Machine Footprint Width

- 1400 - 2300 mm

- Machine Footprint Length

- 4000 - 7500 mm

- Machine Footprint Height

- 1900 - 2300 mm

- Weight

- 1500 - 2500 kg

- Air Pressure

- 6 bar (15–18 CFM at 90 PSI)

- Power Supply

- i

- Working Mechanism

- Continuous or Intermittent

- Automation level

- Fully servo-driven

- Changeover time

- Easy format changeover

- Batch vs. Continuous Operation

- Continuous or Intermittent

- Jogging Control

- Included

- Cleanability

- Yes (stainless steel construction)

- Corrosive resistance (e.g. acids)

- Yes (stainless steel construction)

- Density/particle size

- Various (accommodates a wide range)

- Product adaptability

- Variety of products

- Machine Footprint

- 1400 - 2300 mm W x 4000 - 7500 mm L x 1900 - 2300 mm H

- Weight

- 1500 - 2500 kg

- Material

- Stainless Steel

- Closure Systems

- Hot melt, hot air systems or tuck closure

- Carton Magazine

- Inclined

- Carton Supply Control

- Controlled

- Drive Type

- Servo-driven

- Component Type

- Off-the-shelf components

- Control System

- Siemens or Allen Bradley controls

- Design

- Ergonomic

- Control panel type

- Siemens or Allen Bradley

- Motion type

- Continuous or Intermittent

- Frame sizes

- Various sizes to accommodate large carton sizes

- Closure systems

- Hot melt, hot air, or tuck closure

- Size changeover

- Fully motorized

- Diagnostics

- Remote diagnostics

- Washdown

- IP65 washdown construction

- Electronics and voltages

- Special electronics and voltages