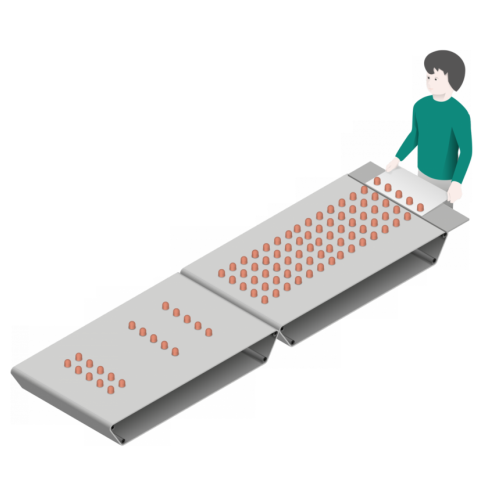

Overflow conveyor for efficient product handling

Streamline your production with overflow conveyors that manage excess product flow, ensuring seamless integration and reducing downtime within your packaging line.

Stores and Transports Overflow Products

The Overflow Conveyor from Theegarten-Pactec offers a robust solution for managing product overflow in confectionery and food production lines. Designed with a three-phase motor driven by an integrated frequency controller, it ensures precise control over product flow and seamless integration with packaging systems. Its key applications include handling excess goods like gummy bears, milk chocolate bars, and peppermint hard candies, maintaining an efficient packaging process.

This conveyor supports continuous and manual operations, featuring quick-access removable support plates for easy cleaning and maintenance. With its pneumatic web tracking control and quick tensioning devices, it guarantees smooth product transfer and reduced downtime. Built with corrosion-resistant materials, it is ideal for environments requiring high hygiene standards. Additionally, the conveyor integrates easily upstream and downstream with existing systems, reducing bottlenecks and optimizing line efficiency. Whether dealing with soft caramels or dishwasher tablets, this conveyor accommodates a wide range of products, backed by Theegarten-Pactec’s engineering expertise and support.

Benefits

- Enhances production flow by efficiently managing overflow, preventing bottlenecks.

- Minimizes downtime with easy access for cleaning and maintenance.

- Ensures precise product handling with pneumatic web tracking and frequency-controlled motors.

- Supports high hygiene standards with corrosion-resistant construction.

- Seamlessly integrates with existing packaging lines for streamlined operations.

- Applications

- Fudge, Hard candies, Caramels, Chocolates, Bouillon cubes, Bubble gum, Toffee, Sweets, Cereals, Jelly products, Effervescent tablets, Dishwasher tablets, Chewing gum

- End products

- Gummy bears, Granola clusters, Fizzy vitamin c tablets, Chocolate fudge pieces, Lemon-scented dishwasher tablets, Caramel chews, Bubble gum balls, Beef bouillon cubes, Peppermint hard candies, Milk chocolate bars, Caramel toffees, Chewing gum sticks, Fruit-flavored jelly beans

- Steps before

- Product processing, Product conveyance, Product sorting

- Steps after

- Packaging, Manual take off, Distribution to packaging machines

- Input ingredients

- bouillon cubes, cereals, chewing gum, bubble gum products, chewy sweets, chocolate products, dishwasher tablets, eclairs, effervescent tablets, hard candies, preformed products, jelly products, krówki, soft caramels, toffee, fudge

- Output ingredients

- packaged bouillon cubes, packaged cereals, packaged chewing gum, packaged bubble gum, packaged chewy sweets, packaged chocolates, packaged dishwasher tablets, packaged eclairs, packaged effervescent tablets, packaged hard candies, packaged preformed products, packaged jelly products, packaged krówki, packaged soft caramels, packaged toffee, packaged fudge

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Motor Type

- Three-phase motor

- Automation

- Frequency controller integrated

- Cleaning Access

- Easy access through removable conveyor support plates

- Maintenance

- Quick tensioning devices for conveyor belts

- Product Transfer

- Smooth transfer with return shafts of 10 mm diameter

- Waste Management

- Underneath sliding waste trays

- Operation Control

- Foot-operated switch for product removal

- Pneumatic Control

- Pneumatic web tracking control

- Working Mechanism

- Three-phase motor driven conveyor

- Speed Control

- Frequency controller integrated

- Cleaning Method

- Manual

- Removable conveyor support plates

- Ease of Maintenance

- Quick tensioning devices for conveyor belts

- Automation Level

- Food-operated switch for product removal

- Product Overflow Handling

- Manual take off of product overflow

- Waste Management

- Underneath sliding waste trays

- Pneumatic Control

- Pneumatic web tracking control

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Pneumatic and manual

- Conveyor belt tensioning

- Quick tensioning devices

- Conveyor support plates

- Removable

- Return shaft diameter

- 10 mm

- Drive mechanism

- Three-phase motor

- Control panel type

- Integrated within the switch cabinet

- Conveyor support plates

- Removable

- Conveyor belt tensioning

- Quick tensioning devices

- Conveyor drive

- Three-phase motor driven

- Pneumatic control

- Web tracking control

- Waste tray design

- Underneath sliding waste trays