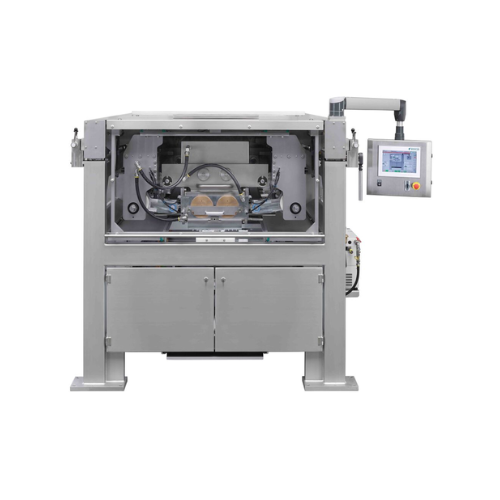

One-shot chocolate depositing system

Enhance your confectionery line with precise, high-speed depositing technology designed for seamless integration into existing production environments, perfect for creating intricate chocolate pralines and filled bars.

Deposits and Moulds Chocolate Confectionery

The PowerShot from Bühler Group is a state-of-the-art one-shot chocolate depositor designed to address the challenges of high-volume, precise confectionery production. This versatile equipment caters to chocolate manufacturers and food processing companies, offering seamless depositing of chocolates, fillings, and inclusions. Suitable for manufacturing a range of end-products such as pralines, truffles, and nut-filled bars, the PowerShot integrates effortlessly into existing production lines with options for spot, ribbon, and one-shot depositing.

Utilizing the latest drive technology, the PowerShot enhances energy efficiency by recycling servo drive energy, reducing operational costs. Its design prioritizes hygiene, allowing easy access for cleaning and maintenance, meeting the highest food safety standards. High-quality depositing tools facilitate swift changeovers between chocolate masses and product types, maximizing throughput with minimized downtime.

Automation is supported by PLC control, enabling integration into broader production systems and ensuring consistency across batches. Customized configurations allow parameters to be tailored to specific product needs, offering flexibility and ensuring the unit functions optimally for your unique requirements. The PowerShot’s robust build, with available corrosion-resistant materials, ensures longevity even under rigorous conditions, making it an invaluable asset for high-speed, continuous operations in the confectionery industry.

Benefits

- Enhances production efficiency with high-volume, precise depositing capabilities.

- Minimizes energy costs by utilizing servo drive energy recycling.

- Facilitates swift product changeovers with user-friendly depositing tools.

- Maintains stringent hygiene standards, simplifying cleaning and maintenance.

- Integrates seamlessly into existing lines, supporting versatile confectionery production.

- Applications

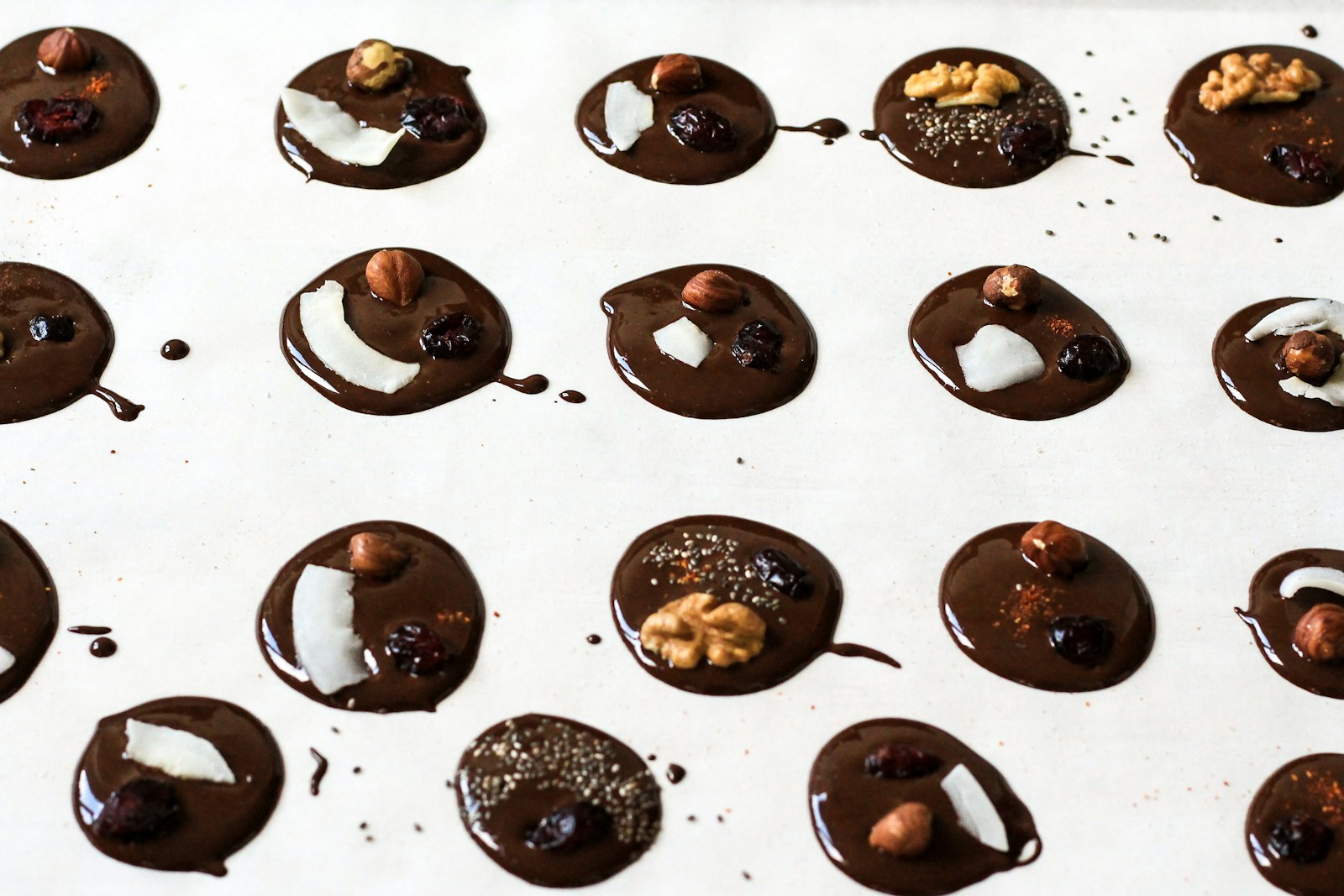

- Snacks, Confectionery, Chocolates, Bars, Moulded products, Tablets, Chocolate, Blocks

- End products

- Filled chocolate bars, Chocolate truffles, Nougat bars, Candy-coated chocolates, Cocoa-based confectionery blocks, Marzipan-filled chocolates, Chocolate pralines, Chocolate blocks, Caramel-filled chocolates, Nut-filled chocolate bars, Assorted chocolate tablets, Chocolate drops, Solid chocolate tablets

- Steps before

- Dough prep, extrusion, shaping, Moulding, forming, Cooling, buffering

- Steps after

- Cooling, buffering, Packing, Palletizing, Sorting, drying

- Input ingredients

- solid chocolate, premixed inclusions

- Output ingredients

- drops, bars, chocolates, tablets, blocks

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Deposit types

- Spot, ribbon, one-shot

- Food safety standards

- Hygienic design

- Energy efficiency

- Intrinsic energy recycling

- Drive technology

- Latest servo drive

- Product flexibility

- Compatible with multiple chocolate products

- Operator safety

- Smart design for maximum safety

- Accessibility

- High accessibility for cleaning

- Changeover time

- Tool change while running

- Production throughput

- High throughput

- Integration capability

- Compatible with existing lines

- Depositing type

- Spot / Ribbon / One-shot

- Automation level

- Manual / PLC / SCADA

- Energy efficiency

- Excellent / Optimized

- Changeover time

- Fast / Minimal downtime

- Cleaning method

- Easy access / Hygienic design

- Integration capability

- Suitable for existing lines

- Flexibility

- High throughput / Multifunctional

- Safety features

- Smart cladding design

- Cleanability

- Easy access for cleaning

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Variable

- Product shape versatility

- Spot, Ribbon, One-shot

- Cladding design

- Smart design with good visibility

- Accessibility

- High accessibility to all areas

- Customizable parameters

- Yes

- Control panel type

- HMI

- Integration possibilities

- Compatible with existing lines

- Flexibility in depositing

- Spot / Ribbon / One-shot

- Hygienic Design

- High accessibility for cleaning