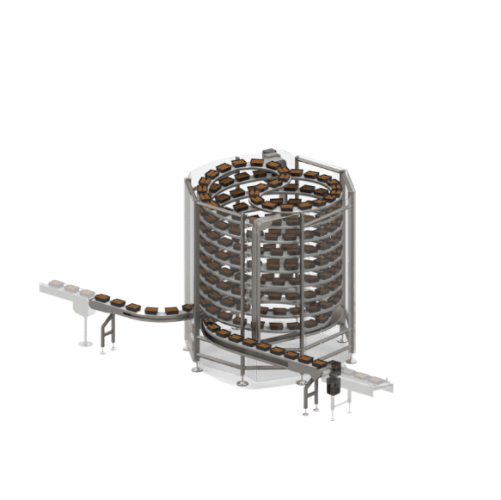

Tray buffering system for downstream absorption

Handle production line disruptions effortlessly by temporarily absorbing trays during packaging flow interruptions, ensuring consistent operation and reducing downtime in your high-speed food processing and packaging operations.

Buffers and Accumulates Loaded Trays

The Tray Buffer from Royal Houdijk is an engineered solution designed to enhance the efficiency of food packaging lines by seamlessly managing downstream interruptions. Incorporating a dynamic spiral accumulator, it occupies minimal floor space while efficiently buffering and accumulating loaded trays. This system is ideal for food manufacturers and packaging companies dealing with products like potato chips, chocolate bars, and cereals. The FIFOTRAY Buffer absorbs operational interruptions by extending its track to store excess trays when a connected wrapper halts. Once the downstream capacity is restored, the system rapidly empties the stored trays, maintaining continuous operation. The buffer is PLC-controlled, ensuring smooth integration with existing production lines and allowing real-time adjustments. Its construction supports high-speed processes, accommodating the packaging of solid end-products efficiently. Customization options are available to fit specific production requirements, with engineering support provided for seamless implementation within your facilities.

Benefits

- Ensures continuous packaging operations by effectively managing stoppages.

- Maximizes production efficiency with minimal floor space footprint.

- Reduces operational costs with rapid buffer emptying and restoration.

- Enhances line productivity with high-speed, automated accumulation.

- Seamlessly integrates into existing systems with flexible PLC control.

- Applications

- Baked goods, Snacks, Confectionery, Packaged food, Sweets

- End products

- Canned soups, Cookies, Hard candies, Cupcakes, Cereal bars, Potato chips, Packaged nuts, Chocolate bars, Crackers, Chewing gum

- Steps before

- Tray Loading

- Steps after

- Wrapping, Packaging

- Input ingredients

- loaded trays

- Output ingredients

- excess trays

- Market info

- Houdijk is known for designing and manufacturing advanced handling and processing equipment for the biscuit and bakery industry, specializing in automated systems to improve efficiency and maintain product quality.

- Buffering Type

- Dynamic spiral accumulator

- Space Requirement

- Minimum required floor space

- Operation Mode

- Automatic/Continuous

- Flexibility

- Absorbs excess trays during downstream stoppages

- Operating Mechanism

- Spiral accumulator adjusts (extends and shortens)

- Working mechanism

- Dynamic spiral accumulator

- Buffering capability

- Absorbs downstream stoppages

- Floor space efficiency

- Minimum required space

- Automation level

- Automatic tray handling based on availability

- Operation flow

- FIFO (First In, First Out)

- Adaptability to stoppages

- Automatically adjusts operation speed

- Batch vs. continuous operation

- Continuous

- Changeover time

- Not specified

- Cleaning method

- Not specified

- Compact footprint

- Minimum required floor space

- Accumulator type

- Dynamic spiral

- Tray absorption mechanism

- Dynamic spiral moves upwards

- Buffer system

- FIFOTRAY BUFFER

- Compact footprint

- Minimum required floor space