Fifo inflow buffer for efficient production lines

Optimize your production flow with a solution that seamlessly absorbs downstream stoppages while maximizing efficiency using advanced curve conveyor technology.

Buffers and Conveys High-Speed Product Flow

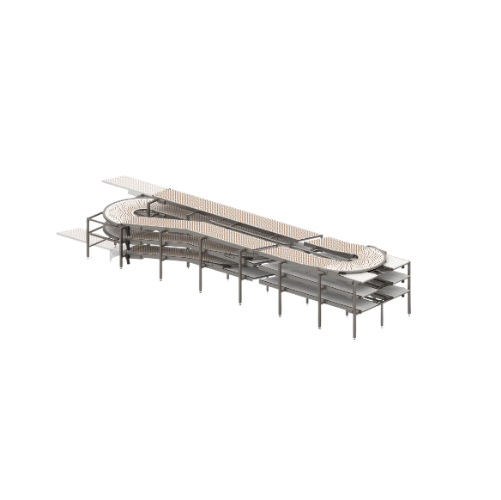

The FIFO Inflow Buffer from Royal Houdijk is engineered to optimize continuous and high-speed product flow in food production, packaging, and manufacturing lines. Featuring a unique u-shaped conveyor configuration, this system is equipped with a movable 180-degree curve conveyor that adjusts to varying buffer levels, effectively managing production halts due to downstream stoppages. Ideal for snacks, sweets, cereals, bakery products, and confectionery, it processes solid, granules, and powder forms, culminating in end-products like potato chips, chocolate bars, and biscuits.

In environments where space is a premium, the Inflow Buffer can be suspended from the ceiling or configured across multiple levels, offering enhanced buffer time without a large footprint. It seamlessly integrates into existing lines, supported by PLC-controlled automation for precise operation.

The buffer handles products efficiently, ensuring minimum downtime through surge mode emptying and is constructed from durable materials to suit food production needs. Maintenance is streamlined with easy access points, ensuring long-term operational reliability while adhering to industry standards.

Benefits

- Enhances line efficiency by absorbing downstream interruptions, promoting uninterrupted production.

- Space-saving design with ceiling suspension and multi-level configurations, ideal for compact manufacturing environments.

- PLC-controlled automation reduces manual oversight, minimizing labor costs.

- Versatile application for various product forms, optimizing production capability.

- Constructed for durability and easy maintenance, ensuring long-term operational consistency.

- Applications

- Snacks, Confectionery, Cereals, Sweets, Bakery products

- End products

- Biscuits, Toffees, Potato chips, Chocolate bars, Puffed rice cereals

- Steps before

- Product Assembly, Process Line Assembly, Pre-buffer Preparation

- Steps after

- Product Sorting, Packing, Distribution, Quality Control

- Input ingredients

- Output ingredients

- Market info

- Houdijk is known for designing and manufacturing advanced handling and processing equipment for the biscuit and bakery industry, specializing in automated systems to improve efficiency and maintain product quality.

- Buffer Configuration

- U-shaped conveyor

- Conveyor Movement

- Movable 180 degree curve

- Buffer Levels

- Minimum to Maximum

- Footprint

- Minimal with multi-level configuration

- Installation Method

- Suspended from ceiling

- Space Efficiency

- Maximizes buffer time

- Operating Mode

- Surge mode for emptying

- Buffer configuration

- U-shaped conveyor

- Buffer level control

- Movable 180 degree curve conveyor

- Buffering mode

- Surge mode

- Space optimization

- Ceiling suspended / Multi-level configuration

- Density/particle size

- Variable depending on product

- Conveyor configuration

- U-shaped

- Movable conveyor

- 180 degree curve

- Buffer level movement

- Minimum to Maximum buffer level

- Space-efficient installation

- Ceiling-suspended / Multi-level

- Conveyor Configuration

- U-shaped

- Movable Conveyor

- 180-degree curve

- Installation Type

- Ceiling-suspended

- Configuration Levels

- Multi-level