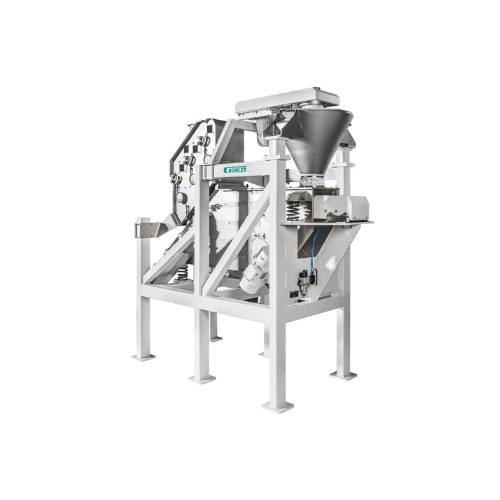

Laboratory winnowing system for cocoa beans

Efficiently crush cocoa beans and separate shells from nibs with precision and control, streamlining your pre-processing phase and enhancing product quality. Ideal for scaling operations or refining product formulations.

Crushes and Separates Cocoa Beans

The LAB Winnower from Bühler Group is designed for precision in cocoa processing, providing a compact solution for labs and small-scale production environments. It employs a frequency-controlled crusher and adjustable air classification to efficiently crush cocoa beans and separate nibs from shells, minimizing product fines and maximizing yield. Capable of processing up to 150 kg/h, this winnower is ideal for producing cocoa nibs, cocoa mass, and chocolate liquor. With its stainless steel construction, the LAB Winnower ensures cleanliness and meets high food safety standards. Its closed design reduces dust pollution, enhancing safety and maintenance ease. Equipped with sampling capabilities, it facilitates process optimization and quality control, integrating seamlessly into pilot and continuous operations within cocoa and chocolate processing industries.

Benefits

- Ensures maximum cocoa yield with precise crushing and separation.

- Enhances food safety and hygiene with stainless steel construction.

- Facilitates process optimization and quality control through sampling capabilities.

- Reduces product waste and increases efficiency with adjustable air classification.

- Minimizes maintenance efforts with dust-reducing closed design.

- Applications

- Chocolate, Cocoa

- End products

- Chocolate couverture, Chocolate liquor, Cocoa nibs, Chocolate bars, Cocoa mass

- Steps before

- Roasting, Grinding

- Steps after

- Quality analysis, Packing

- Input ingredients

- cocoa beans

- Output ingredients

- cocoa nibs, cocoa shells

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Throughput

- up to 150 kg/h

- Material

- Stainless steel processing zone

- Automation

- Frequency-controlled crusher

- Adjustable air classification

- Yes

- Working mechanism

- Sieving and air classification

- Integrated steps

- Crusher and separator

- Automation level

- Frequency-controlled crushing

- Batch vs. continuous operation

- Continuous mode

- Cleaning method

- Minimal dust pollution due to closed design

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Hygienic design

- Stainless steel

- Cocoa Processing

- Cocoa beans, Cocoa nibs

- Separation Efficiency

- High

- FDA materials

- Yes

- EHEDG certification

- Yes

- 3A Sanitary Standards

- Yes

- CE marking

- Yes

- GMP Compliance

- Yes

- Machine footprint

- Compact

- Discharge method

- Sieving and air classification

- Control panel type

- Frequency-controlled

- Material of construction

- Stainless steel

- Cocoa bean processing capacity

- Up to 150 kg/h

- Aspiration channel adjustment

- Adjustable

- Vacuum control

- Precise control

- Hygienic design

- Closed, reduces dust pollution

- Control panel type

- Frequency-controlled crusher

- Crushing intensity adjustment

- Matches cocoa bean characteristics

- Air classification adjustment

- Adjustable aspiration channel and vacuum

- Machine design

- Closed design