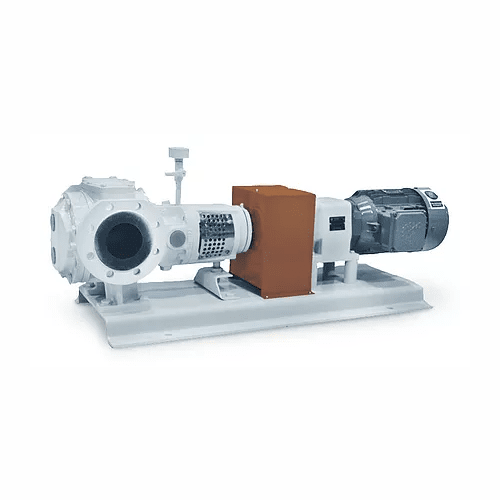

Chocolate pump for confectionery production

Effortlessly pump and convey a range of chocolate-based products with precision, ensuring smooth flow without overheating, making it ideal for maintaining product integrity during confectionery processing.

Pumps and Conveys Liquid Chocolate Efficiently

The Chocolate Pump by MacIntyre Chocolate Systems is an essential component for chocolate manufacturers and confectionery producers. Constructed with a robust cast iron jacketed body, the pump features an impeller and main drive shaft made of steel, supported by interchangeable liners and both cast iron and bronze bearings, ensuring durability and reliability. Its positive displacement design can be operated in both directions for versatile integration into your production line. Capable of managing various chocolate consistencies, including pure chocolate, compound, couverture, praline, and cream fillings, it operates at slow speeds to prevent chocolate burning. Suitable for vertical pumping up to 4 meters or horizontal runs over 100 meters, it maintains a low energy footprint. Its optional stainless steel configuration and jacketed chocolate pipework cater to specific needs, while advanced pump control options enable efficient operation. This unit seamlessly fits into processes demanding continuous or variable speed operations in food, confectionery, and chocolate manufacturing industries.

Benefits

- Enhances production efficiency with gentle and consistent chocolate transfer, preventing product degradation.

- Minimizes energy costs through low-speed operation and optimal motor control.

- Customizable to meet specific production needs with optional stainless steel and pump control configurations.

- Capable of long-distance and vertical pumping, supporting flexible facility layouts.

- Reduces maintenance downtime with interchangeable liners and continuously lubricated bearings.

- Applications

- Couverture, Truffle, Praline, Compound, Sweets, Creme fillings, Chocolate

- End products

- Praline candies, Chocolate truffles, Couverture chocolate blocks, Chocolate coated biscuits, Coated nuts, Chocolate creams, Filled chocolate pralines, Chocolate bars, Chocolate spreads, Chocolate caramels

- Steps before

- Block Melting, Chocolate Storage, Chocolate Filtering

- Steps after

- Chocolate Rework, Chocolate Packaging, Cooling

- Input ingredients

- pure chocolate, compound, couverture, praline, truffle, creme fillings

- Output ingredients

- pumped pure chocolate, pumped compound, pumped couverture, pumped praline, pumped truffle, pumped creme fillings

- Market info

- Macintyre Probat is known for manufacturing specialized industrial machinery, particularly in the cocoa and chocolate processing industry, offering engineered-to-order solutions with a reputation for innovation and reliability in their equipment designs.

- Material

- Cast iron jacketed body, steel shaft

- Liner Material

- Interchangeable liners

- Bearing Material

- Cast iron and bronze

- Inlet/Outlet Size

- 50mm / 80mm / 100mm, BS 4504 PN16

- Flow Rate Variability

- Dependent on pipeline length and height

- Driving System

- Geared engine

- Suction Type

- Flooded suction

- Speed Control

- Fixed or Variable Speed

- Directional Usage

- Can be used in either direction

- Pumping Capability

- Heavy duty, up to 4 meters vertically and 100 meters horizontally

- Energy Consumption

- Low energy consumption

- Construction Type

- Bare shaft positive displacement

- Working mechanism

- Bare shaft positive displacement

- Inlet / outlet sizing

- 50mm / 80mm / 100mm, BS 4504 PN16

- Flow rate

- Dependent on pipeline length and height

- Suction type

- Flooded suction

- Speed control

- Fixed or Variable Speed

- Bidirectional operation

- Can be used in either direction

- Operation speed

- Run at slow speed

- Height capability

- Higher than 4 meters vertically

- Length capability

- Longer than 100 meters horizontally

- Abrasion resistance

- Yes

- Biological compatibility

- Food grade

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes

- Construction Material

- Cast iron jacketed body

- Main Drive Shaft Material

- Steel

- Bearing Material

- Cast iron and bronze

- Interchangeable Liners

- Yes

- Inlet / Outlet Size

- 50mm / 80mm / 100mm, BS 4504 PN16

- Speed control

- Fixed or Variable Speed

- Direction of operation

- Can be used in either direction

- Optional extras

- Pump control, Jacketed chocolate pipework, Stainless steel manufacture

- Higher output pumps

- Available if required