Flowpack packaging machine for chocolate products

Effortlessly wrap and preserve large quantities of chocolate and sweet snacks, ensuring enhanced shelf life and product protection, while optimizing packing speed and material flexibility for diverse formats.

Wraps and Seals Chocolate and Food Products Efficiently

The SELMI WRAP 400 PLUS is a compact flow pack machine designed to optimize the packaging process for chocolates and a variety of food products. Its standout feature is the use of Box Motion technology, ensuring precise cutting and sealing for diverse product sizes. Capable of wrapping and sealing chocolate bars, truffles, pralines, and more, it enhances shelf life and presentation. With a throughput of up to 100 packs per minute, the machine’s continuous, high-speed operation is tailored for chocolate manufacturers and confectionery producers. Engineered with an innovative thermal sealing system and an integral cooled surface, it minimizes chocolate melting during the sealing phase. The pneumatically expandable reel holder with caliper positioning, customizable forming box, and integrated thermal printer streamline the process, enhancing operational efficiency. Ideal for small laboratories and large-scale packaging facilities, the WRAP 400 PLUS supports films up to 400mm wide and operates seamlessly in environments up to 32°C. Its durable stainless steel finish ensures easy cleaning and maintenance, while the ‘No Product-No Bag’ detector prevents material waste, making it a cost-effective solution for modern food packaging needs.

Benefits

- Maximizes production efficiency with a high-speed capacity of up to 100 packs per minute.

- Enhances shelf life and product integrity through precise Box Motion cutting and sealing.

- Minimizes material waste with the 'No Product-No Bag' detector, optimizing resource use.

- Ensures easy integration into diverse production lines with customizable components.

- Facilitates sustainable operations with options for eco-friendly wrapping materials.

- Applications

- Chocolate, Sweets, Food products, Snacks

- End products

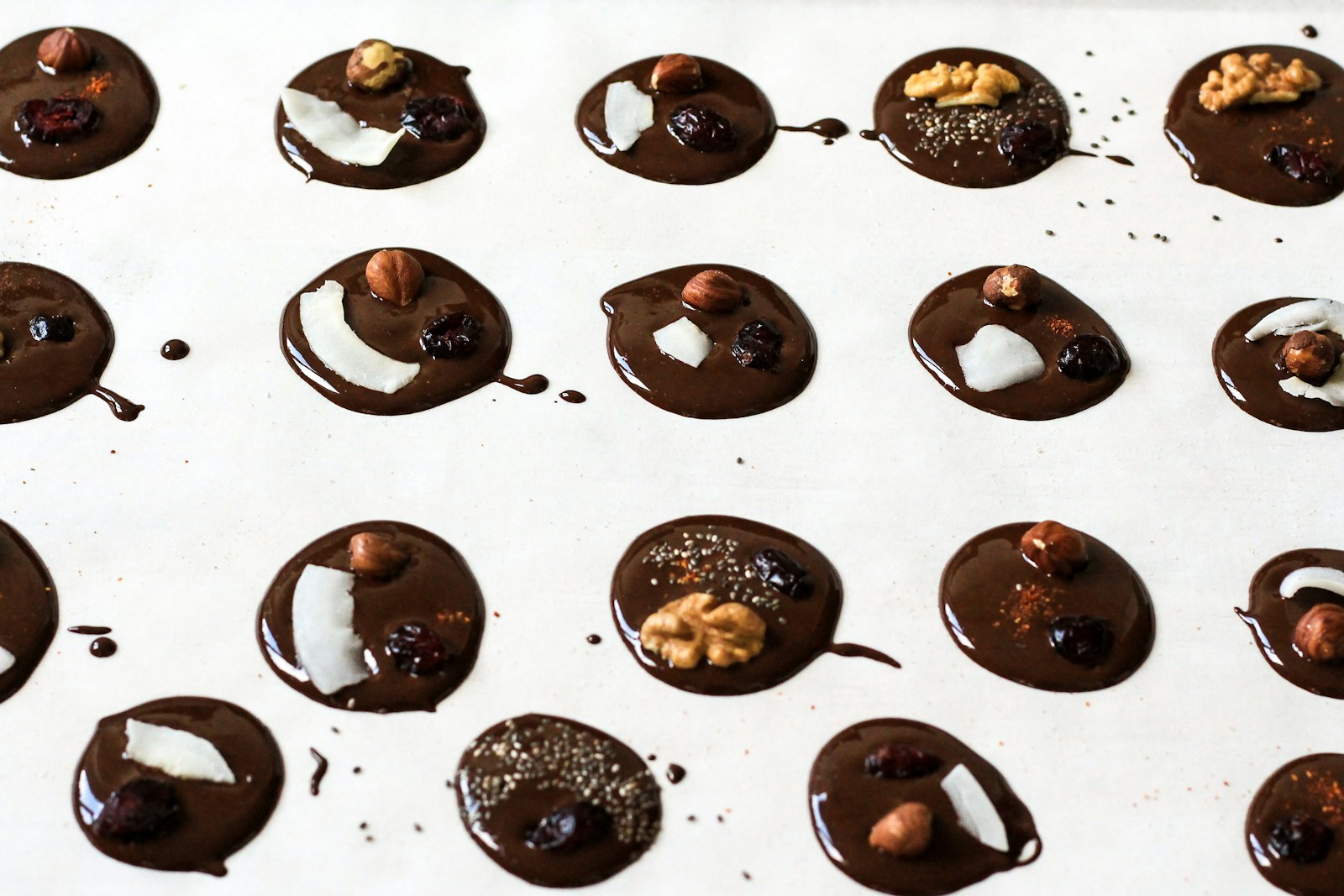

- Packed chocolate bars, Pralines, Chocolate bars, Ganache-filled chocolates, Truffles, Chocolate-coated snacks, Packed sweet snacks, Chocolate drops

- Steps before

- Batch Preparation, Product Alignment, Temperature Control

- Steps after

- Packaging Inspection, Labelling, Dispatch

- Input ingredients

- chocolate, food products, flow wrap materials, wrapping material, paper, environmentally friendly products

- Output ingredients

- wrapped chocolate, packaged food products, sealed flow packs, flow packed products

- Market info

- Selmi is renowned for manufacturing high-quality chocolate processing equipment, such as tempering, enrobing, and cooling machines, with a strong reputation for precision, innovation, and reliability in the confectionery and chocolate industry.

- Maximum Product Width

- 130 mm

- Maximum Product Height

- 45 mm

- Maximum Speed

- 100 ppm

- Film Width

- Up to 400 mm

- Electrical Specification

- 220 V monofase - 50/60 Hz

- Power Required

- 3 Kw - 16 A - 3 poles

- Optimal Room Temperature

- 20/25°C, maximum 32°C

- Dimensions

- h. 1800 mm, l. 2500 mm, p. 720 mm

- Compressed Air Requirement

- 100 litres/min - minimum 6 bar

- No Product-No Bag Detector

- Standard

- Thermal Transfer Printer

- Included

- Sealing System

- Box Motion Technology

- Cutting and Closing System

- Innovative cam design

- Product Exit Belt

- Made with straps/cords

- Jaws/Sealing Jam Width

- 150 mm

- Working mechanism

- Flow pack system

- Packaging speed

- Up to 100 ppm

- Automation level

- PLC

- Product detection system

- No Product-No Bag detector

- Film width capability

- Up to 400 mm

- Product size compatibility

- Various sizes and formats

- Sealing technology

- Innovative thermal sealing system

- Loading area configuration

- Customizable length

- Motion technology

- Box Motion

- Cleanability

- Easy to clean with stainless steel finish

- Corrosive resistance (e.g. acids)

- Stainless steel offers resistance to corrosion

- Density/particle size

- Handles various formats and sizes

- Machine footprint

- h. 1800 mm, l. 2500 mm, p. 720 mm

- Reel holder

- Pneumatically expandable

- Loading area length

- 1 metre (extendable)

- Discharge method

- Packaged product exit belt with straps/cords

- Control panel type

- User interface for customisation

- Control panel type

- Integrated HMI

- Integration possibilities

- Customizable forming box

- Customizable loading area

- Extendable on request

- Customizable film width

- Up to 400mm

- Product exit direction

- Left to right or right to left