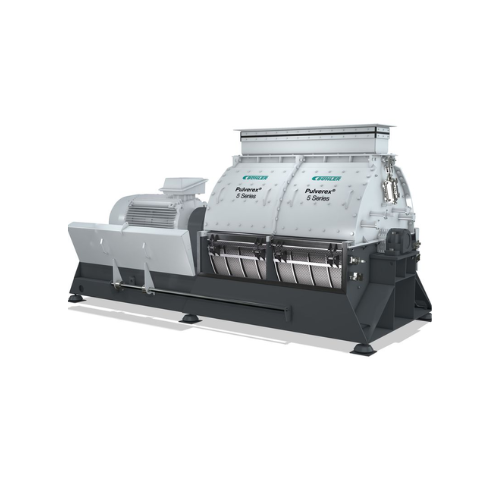

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, utilizing a unique hybrid design that merges pulverizing efficiency with the versatility of traditional hammer mills, ideal for continuous operations.

Delivers Energy-Efficient Fine Grinding and Pulverizing

The Pulverex™ 5 Series from Bühler Group is a hybrid hammer mill and pulverizer engineered to enhance efficiency across diverse industrial applications. Maintaining the screen structure of a conventional hammer mill, it integrates pulverizer impact plates, ensuring very fine particle grinding at high throughput levels. Designed for continuous operation, it is ideal for an array of applications, delivering optimal performance in processing fish pellets, soy protein isolates, semiconductor wafers, and more. This machine efficiently handles up to several tons per hour, significantly reducing energy consumption through a hybrid design. Its robust construction features abrasion-resistant materials, with wear parts like impact plates absorbing most of the grinding, which minimizes maintenance downtime. Compatible with a wide range of materials, from food products to electronic materials, it ensures low wear and easy maintenance. Customizable options are available, supported by Bühler’s engineering expertise, to suit specific industry requirements.

Benefits

- Ensures consistent product quality with fine and uniform particle size distribution.

- Increases production efficiency by combining hammer milling and pulverizing in one machine.

- Lowers operational costs through reduced energy consumption and wear-resistant parts.

- Adapts to diverse industrial needs with versatility in grinding a wide range of materials.

- Minimizes maintenance time thanks to quick-change wear parts and robust construction.

- Applications

- Snacks, Grain, Cosmetics, Chocolate, Chemicals, Printing inks, Pulses, Spices, Aqua feed, Biomass, Batteries, Pulse processing, Cocoa, Animal feed, Pasta, Pet food, Paints, Electronic materials, Baked goods, Oilseeds, Wheat, Confectionery, Coatings

- End products

- Spaghetti, Dog kibble, Whole wheat flour, Wood pellets, Lithium-ion battery components, Lithium-ion batteries, Potato chips, Cocoa powder, Candy coatings, Curry powder, Fish pellets, Semiconductor wafers, Soy protein isolate, Pelleted livestock feed, Lentil flour, Inkjet printer cartridges, Rye bread, Sunflower oil, Cosmetic emulsions, Chocolate bars, Automotive coatings

- Steps before

- Dehulling, Dough prep, Conditioning, Sorting, Weighing, Dosing

- Steps after

- Packing, Palletizing, Sifting, grading, Optical sorting, Moulding, forming

- Input ingredients

- raw materials, aqua feed ingredients, pulse ingredients, pet food ingredients, biomass, cocoa beans, coffee beans, oilseeds, wheat, grain

- Output ingredients

- fine granulation products, aqua feed, processed pulses, processed pet food, ground biomass, cocoa powder, coffee grounds, processed oilseeds, milled wheat, milled grain

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Abrasion resistance

- Yes

- Capacity

- High capacity

- Energy Consumption

- Efficient / Low energy

- Granulation

- Fine granulation

- Operation type

- Continuous

- Particle size distribution

- Uniform

- Screen area

- Large

- Tip speed

- Optimized

- Wear parts

- Quick change

- Working Mechanism

- Hammer mill and pulverizer hybrid

- Integrated Steps

- Single-stage grinder or dedicated fine grinder

- Automation Level

- Manual / PLC / SCADA

- Energy Efficiency

- More efficient grinding, less energy consumed

- Changeover Time

- Quick change of wear parts

- Wear and Maintenance

- Low wear and maintenance

- Abrasion resistance

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Easy to clean

- Discharge method

- Air-swept design

- Screen area

- Large

- Hybrid design

- Hammer mill and pulverizer

- Rotor configuration

- Staggered

- Clustered hammers

- Yes

- Impact plates

- Double

- Control panel type

- PLC / HMI

- Integration possibilities

- SCADA / DCS

- Screen structure

- Hybrid

- Rotor configuration

- Staggered

- Impact plates

- Modular / Quick-change