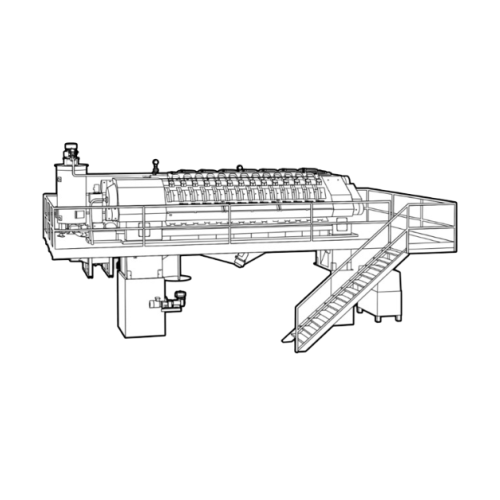

Cocoa pressing plant for high-capacity cocoa liquor processing

Optimize your cocoa processing by converting cocoa liquor into high-quality cocoa butter and cocoa cake efficiently, catering to the high demands of chocolate production.

Presses and Separates Cocoa Liquor into Butter and Cake

The Cocoa Pressing Plant HHP 14 from Petzholdt-Heidenauer is engineered to streamline high-capacity cocoa processing. This plant is equipped with advanced “Coriolis” Flowmeter Measurement Technology, ensuring consistent cocoa liquor press results. It features a programmable control system that tailors pressing conditions to specific cocoa mass qualities. Operating with capacities up to 2700 kg/h at varying residual butter contents, the HHP 14 is optimal for producing cocoa butter and cake with precision. Its integration in automated processing lines is simplified through high-performance “Radial-Piston” pumps and adaptable filling systems, allowing for seamless scalability. With a connected load of 38 kW and designed to occupy a space of 10800 x 6000 mm, it supports efficient energy utilization while handling intensive production demands. Enhanced monitoring capabilities, such as scale-based butter weight control and electronic ram positioning, ensure reliable performance for chocolate manufacturers and cocoa producers.

Benefits

- Maximizes production efficiency with capacities up to 2700 kg/h, accommodating high-demand operations.

- Tailors production parameters with programmable control, ensuring consistent product quality.

- Minimizes energy use with optimized motor design and hydraulic systems.

- Enhances operational flexibility through adjustable pressing conditions and filling systems.

- Facilitates seamless integration into existing lines, promoting continuous, automated workflows.

- Applications

- Cocoa products, Sweets, Chocolate, Snacks

- End products

- Cocoa butter, Chocolate truffles, Filled chocolates, Cocoa powder, Chocolate coatings, Cocoa liquor, Cocoa cake, Chocolate bars

- Steps before

- Cleaning, Pre-Treating, Winnowing, Sterilising, Alkalising, Roasting, Grinding

- Steps after

- Chocolate Making, Mixing, Pre-Refining, Refining, Conching, Sugar Grinding

- Input ingredients

- cocoa liquor

- Output ingredients

- cocoa butter, cocoa cake

- Market info

- Hamburg Dresdner Maschinenfabriken GmbH is known for expertise in manufacturing industrial machines for the cocoa, chocolate, and confectionery industries, particularly focusing on roasting, grinding, and refining processes. They have a strong reputation for quality and innovation.

- Capacity

- up to 2700 kg/h

- Residual Butter Content

- 22 to 24%

- Residual Butter Content

- 10 to 12%

- Residual Butter Content

- 8-10%

- Number of Pots

- 14

- Pot Diameter

- 500 mm

- Filling Weight per Pot

- 18.5 kg

- Total Filling Weight

- 260 kg

- Hydraulic Pressure

- up to 580

- Pressure on Cocoa Mass

- up to 850

- Maximum Speed of Main Ram

- 320 mm/min

- Required Space

- 10800 x 6000 mm

- Connected Load

- 38 kW

- Automation level

- Programmable press control

- Batch vs. continuous operation

- Batch

- Measurement technology

- Coriolis Flowmeter

- Pressing cycles control

- Variable, based on weight, ram way, or time

- Filling system

- High throughput capable

- Filling time optimization

- Special matched Filling Pumps

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- 10800 x 6000 mm

- Control panel type

- Programmable press control

- Filling system

- Latest Coriolis Flowmeter Technology