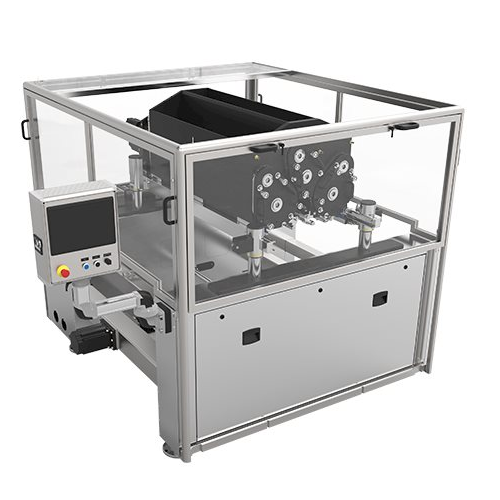

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, this solution minimizes product waste while handling masses with various viscosities and inclusions. Its flexibility in adjusting head movements and extrusion options ensures seamless integration into diverse production lines, fostering creativity and efficiency.

Processes and Deposits Diverse Masses with Precision

The Alice™ from AASTED is a versatile extruder and depositor designed for the bakery, confectionery, and chocolate industries. Crafted to handle masses ranging from high to low viscosity, it precisely processes and deposits various formulations, including those with inclusions or different temperatures. The unique FlexBooster™ and CamRotor™ technologies ensure gentle mass handling, reducing shearing and product waste. Applications span from chocolate bars to cream-filled doughnuts, with options for single, double, or triple head configurations, allowing multi-mass product creation. Capable of continuous operation and adjustable for manual or automated processes, it integrates into existing lines with ease. The Alice™ supports efficient energy use with reduced booster speeds and enables thorough cleaning with offline hosing and easy disassembly, ensuring minimal downtime. Customizable configurations are available to meet specific production needs, backed by AASTED’s engineering expertise.

Benefits

- Optimizes production flexibility with multi-head configuration for diverse product ranges.

- Minimizes product loss through advanced mass handling technologies, ensuring quality output.

- Enhances line efficiency with seamless integration and continuous operation.

- Lowers energy usage via reduced booster speeds, promoting cost-effective production.

- Streamlines maintenance with easy cleaning and quick disassembly, decreasing downtime.

- Applications

- Baked goods, Bakery, Confectionery, Chocolate products, Sweets

- End products

- Filled chocolates, Layered pastries, Cream-filled doughnuts, Truffles, Jelly-filled treats, Chocolate coated confections, Energy bars with inclusions, Marzipan candies, Fudge, Custard-filled tarts, Biscuit-based products, Caramel-centered pastries, Chocolate-coated fruits, Soft nougat, Pralines, Chocolate bars, Caramel-filled chocolates, Mousse desserts, Nougat sweets

- Steps before

- Feeding, Mixing, Melting

- Steps after

- Depositing, Enrobing, Cooling, Cleaning, Packing

- Input ingredients

- high viscosity masses, low viscosity masses, masses with inclusions, tempered chocolate mass, chocolate mass

- Output ingredients

- extruded masses, deposited masses, products with inclusions, chocolate products, with different shapes, with different fillings

- Market info

- Aasted is known for its expertise in manufacturing equipment for the chocolate, bakery, and confectionery industries, offering solutions like tempering, molding, and baking machinery with a strong reputation for innovation and quality.

- Capacity

- Up to 2.5 tons/hr

- Melting Tank Capacity

- 150 kg to 3, 000 kg

- Head Movement

- Vertical and Horizontal

- Head Options

- Single, Double, Triple

- Cleaning Method

- Manual and In-line

- Automation

- Manual and Automated

- Extrusion Precision

- Exceptionally precise

- Working mechanism

- Extrusion and deposition

- Automation level

- Manual / Automated with vertical and horizontal head movement

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual / Off-line hosing-down / In-line cleaning

- Shearing control

- Minimized to prevent waste

- Inclusion handling

- Handles masses with inclusions

- Quick changeover capability

- Easy and quick changeover

- Head configuration

- Single, double, or triple head

- Cleanability

- Easy cleaning, hosedown capability

- Density/particle size

- Handles high to low viscosity

- Tank capacity

- 150 kg to 3, 000 kg

- Discharge method

- Various head movements

- Head configuration

- Single, double, or triple head

- Weight handling

- Light weight parts

- Head Movement

- Manual / Automated Vertical / Vertical and Horizontal

- Head Configuration

- Single / Double / Triple

- Cleaning Method

- Easy Cleaning / Quick Changeover / Hosedown / In-line Cleaning

- Tool Customization

- QuickShift™ Tools / Customized Tools