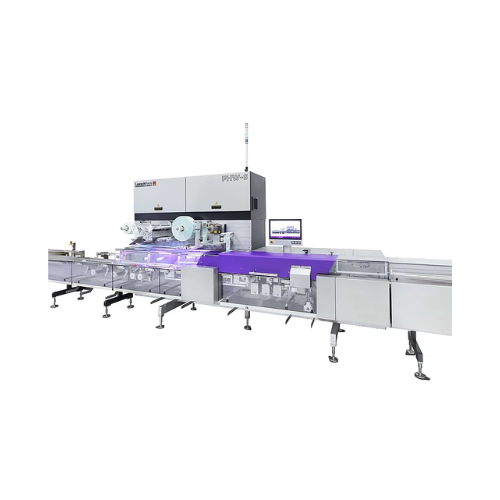

Horizontal flow wrap solution for chocolate bars

Achieve high-speed precision in packaging with a machine designed to handle diverse products and flexible pack styles, optimizing your production line and ensuring efficient wrapping of everything from chocolate bars to soap bars without compromising on quality.

Efficiently Packs and Wraps Diverse Products

The FHW-S Horizontal Flow Wrap Machine from LoeschPack is engineered to offer unparalleled flexibility and efficiency in high-speed packaging. It features an innovative feeding system capable of processing up to 2,100 products per minute, making it ideal for confectionery, food, and pharmaceutical industries. This machine seamlessly handles various products, including chocolate bars, cookies, and pharmaceutical tablets, with easy transitions between packaging materials like plastic and paper-backed wrappers. Integrated automation ensures precise and continuous operations, while the modular design allows for easy integration with upstream and downstream systems. Built for efficiency, the FHW-S minimizes energy consumption and is equipped with auto-splice technology for uninterrupted film feeding. Available materials include durable stainless steel for robust performance, and it adheres to strict hygiene and ergonomic standards, ensuring low maintenance with accessible working areas for easy cleaning.

Benefits

- Achieves high-speed packaging with a throughput of up to 2,100 products per minute.

- Offers seamless material transition at the touch of a button, enhancing operational flexibility.

- Reduces downtime with quick changeover capabilities and auto-splice technology.

- Ensures top hygiene standards with easy-to-clean design and accessible work areas.

- Integrates effortlessly with existing production lines, optimizing overall line efficiency.

- Applications

- Food, Cookies, Wafers, Granola bars, Pharmaceuticals, Confectionery, Non-food, Chocolate, Protein bars

- End products

- Fruit gum rolls, Chocolate bars, Multivitamin tablets, Cleaning pellets, Soap bars, Chewing gum sticks

- Steps before

- Feeding, Distribution, Buffering

- Steps after

- Secondary Packaging, End-of-Line Packaging, Cartoning

- Input ingredients

- chocolate tablets, chocolate bars, granola bars, protein bars, chewing gum sticks, chewing gum tabs, chewing gum pellets, pressed candy, fruit gum rolls, cookies, wafers

- Output ingredients

- packaged chocolate tablets, packaged chocolate bars, packaged granola bars, packaged protein bars, packaged chewing gum sticks, packaged chewing gum tabs, packaged chewing gum pellets, packaged pressed candy, packaged fruit gum rolls, packaged cookies, packaged wafers

- Market info

- Loesch Pack Piepenbrock Group is known for its expertise in manufacturing innovative packaging machinery, particularly for confectionery, pharmaceuticals, and food industries, emphasizing high efficiency, precision, and customization, with a strong reputation for quality and reliability.

- Speed

- Up to 2, 100 products per minute

- Film Speed

- Up to 205 meters per minute

- Automation

- High-performance feeding system

- Flexibility

- Single or multipacks, taut or loose packs

- Packaging Material

- Plastic and paper-backed wrappers, laminates

- Changeover Time

- Touch-of-a-button changeover

- Operation Type

- Designed for three-shift operation

- Automation level

- PLC / High-Speed Operation

- Changeover time

- Short / Quick

- Packaging flexibility

- Single packs / Multipacks

- Material adaptability

- Plastic / Paper / Laminates

- Operating speed

- Up to 2, 100 products/min

- Film speed

- Up to 205 meters/min

- Feeding system

- Innovative / High-performance

- Operation shift capacity

- Three-shift operation

- CIP/SIP

- High hygienic standards

- Cleaning method

- Easy maintenance

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Packaging material flexibility

- Plastic, paper-backed wrappers, laminates

- Changeover to paper from plastic

- At the touch of a button

- Product Shape

- Tablet / Bar

- Packaging Flexibility

- Single / Multipack / Taut / Loose

- Cut Style

- Zigzag / Straight

- Packaging Material

- Plastic / Paper-backed / Laminates

- Product State

- Pre-packed / Unpacked / Single / Pre-grouped

- Operation Mode

- Three-shift operation

- Footprint

- Compact, space-saving modular design

- Machine Type

- Horizontal flow wrap machine

- Product Flexibility

- Handles single and pre-grouped products

- Format Range Flexibility

- Wide variety of pack styles and format ranges

- Pack Style Options

- Single packs, multipacks, taut or loose

- Pack Style Cuts

- Zigzag or straight cut

- Gusset Fold

- Available

- Film Speed

- Up to 205 meters per minute

- Feeding System

- Innovative high-performance feeding

- Product Types Handled

- Chocolates, bars, tablet-shaped products

- Control Panel Type

- easyMI interface

- Packaging Material Flexibility

- Plastic, paper-backed wrappers, laminates

- Changeover Mechanism

- Switch from plastic to paper at the touch of a button

- Pack Style Options

- Single packs, multipacks, taut, loose, with/without gusset fold, grooved, zigzag/straight cut